2020 гидравлический гибочный станок высокого качества для светового полюса Гарантия: 4

- Категория: Оборудование для обработки металлических листов >>>

- Поставщик: Maanshan,Durmapress,Machinery,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 31535.35 $* | 33112.34 $* |

| Aug-17-2025 | 31270.99 $* | 32834.57 $* |

| Jul-17-2025 | 26235.97 $* | 27547.35 $* |

| Jun-17-2025 | 30740.77 $* | 32277.59 $* |

| May-17-2025 | 26765.90 $* | 28103.70 $* |

| Apr-17-2025 | 30210.22 $* | 31721.78 $* |

| Mar-17-2025 | 29945.34 $* | 31442.12 $* |

| Feb-17-2025 | 29680.19 $* | 31164.33 $* |

| Jan-17-2025 | 29415.56 $* | 30886.64 $* |

Характеристики

Product Description

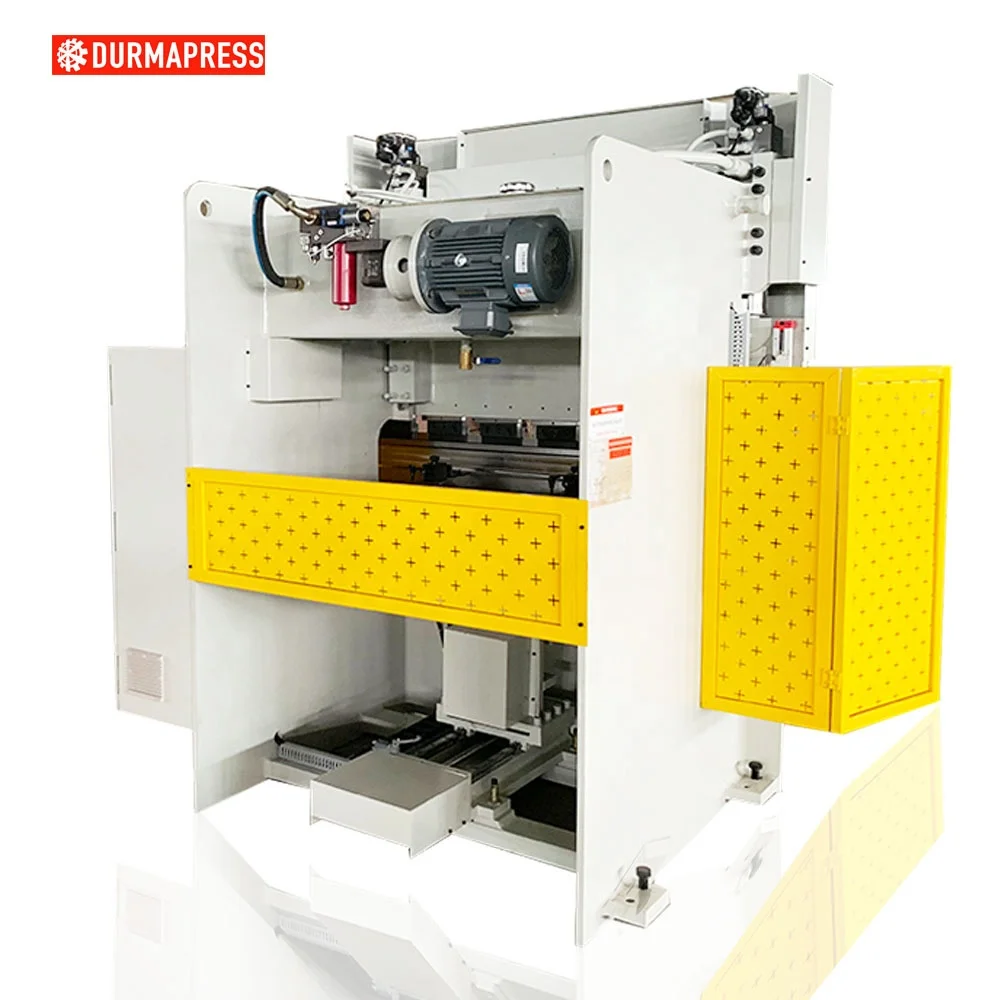

1. Main Features:

● Brand-new industry design integrated with modern aesthetic concept, high-quality fabrication technology with simple and elegant appearance.

● Latest high-frequency responding hydraulic control technology, higher speed, more efficient, higher precision.

● Heat treatment of the rack, rigidity optimization verification of entire machine, research and application of hydraulic compensation mechanism jointly guarantee bending precision of MB8 series Hydralic Press Brake Machine.

● Optimal ratio of parameters and top-level core configuration ensure stable performance, easy operation.

● MB8 standard 2 axis backgauge system, as to complex shape work pieces, 4 or 5 axes back gauge system and corresponding dies are available for bending of complicated shaped workpieces.

● CNC Press Brake Machine using closed-loop electro-hydraulic servo control technology, slider position signals can be feedback to NC system by bilateral gratings, then NC system adjusts the amount of fuel tank by changing the synchronous valve opening size, hereby controlling the slider (Y1,Y2) running with same frequency, maintaining the parallel state of the worktable.

● As for different plate, CNC system can automatically control the table deflection compensation resulting in uniform length of all workpiece angles.

● The use of hydraulic deflection compensation gives access to uniform full length workpieces . Hydraulic deflection compensation consists of a set of oil cylinders, which can make the table occurs relative movement and form an ideal convex curve, ensuring the relative position relationship with slider keep unchanged. Compensation values are subject to plate thickness and properties of material to be cut.

2. Main Configuration:

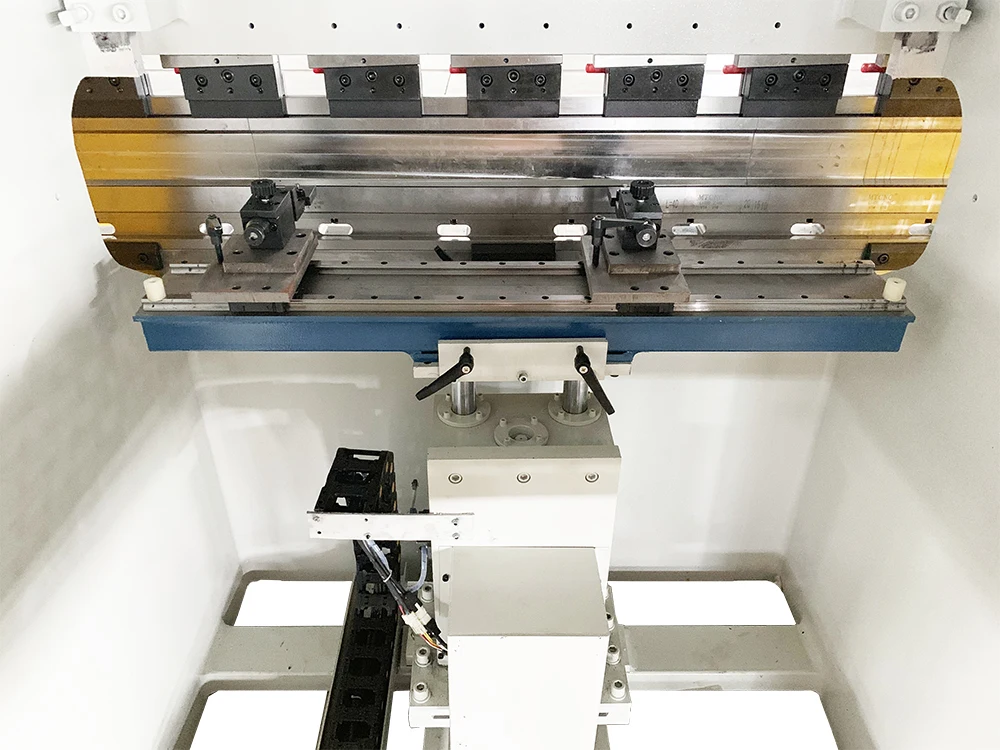

√ Holland DELEM DA66T CNC controller

√ Grating ruler controls depth of Y1 and Y2 axis( y1 / y2-axis 0.01mm )

√ Servo motor drive and control X axis(X-axis 0.05mm ), manually adjusts R axis movement up and down, stopping finger easily move along the cylindrical guide rail

√ Maintain the accuracy of HIWIN ball screw and linear guide of 0.01mm

√ Front carrier position can be adjusted along the linear guide rail in the worktable direction

√ Use Germany Rexroth closed-loop electro-hydraulic servo synchronous control system

√ Germany EMB oil tube connector

√ Germany Siemens main motor

√ France Schneider Electrics

√ Hydraulic and electrical overload protection

√ Upper are mechanical fast pinching dies. Lower are double-V replaceable dies

3. Safety Standard:

● 1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

● Front protection device for protecting finger ( safe light curtain )

● South Korea KACON Pedal switch ( 4 safety grade )

● Rear metal safeguards and CE standard

● Safety relay monitors completed with pedal switch, safety protection

● Safety standards(2006/42/EC)

● Brand-new industry design integrated with modern aesthetic concept, high-quality fabrication technology with simple and elegant appearance.

● Latest high-frequency responding hydraulic control technology, higher speed, more efficient, higher precision.

● Heat treatment of the rack, rigidity optimization verification of entire machine, research and application of hydraulic compensation mechanism jointly guarantee bending precision of MB8 series Hydralic Press Brake Machine.

● Optimal ratio of parameters and top-level core configuration ensure stable performance, easy operation.

● MB8 standard 2 axis backgauge system, as to complex shape work pieces, 4 or 5 axes back gauge system and corresponding dies are available for bending of complicated shaped workpieces.

● CNC Press Brake Machine using closed-loop electro-hydraulic servo control technology, slider position signals can be feedback to NC system by bilateral gratings, then NC system adjusts the amount of fuel tank by changing the synchronous valve opening size, hereby controlling the slider (Y1,Y2) running with same frequency, maintaining the parallel state of the worktable.

● As for different plate, CNC system can automatically control the table deflection compensation resulting in uniform length of all workpiece angles.

● The use of hydraulic deflection compensation gives access to uniform full length workpieces . Hydraulic deflection compensation consists of a set of oil cylinders, which can make the table occurs relative movement and form an ideal convex curve, ensuring the relative position relationship with slider keep unchanged. Compensation values are subject to plate thickness and properties of material to be cut.

2. Main Configuration:

√ Holland DELEM DA66T CNC controller

√ Grating ruler controls depth of Y1 and Y2 axis( y1 / y2-axis 0.01mm )

√ Servo motor drive and control X axis(X-axis 0.05mm ), manually adjusts R axis movement up and down, stopping finger easily move along the cylindrical guide rail

√ Maintain the accuracy of HIWIN ball screw and linear guide of 0.01mm

√ Front carrier position can be adjusted along the linear guide rail in the worktable direction

√ Use Germany Rexroth closed-loop electro-hydraulic servo synchronous control system

√ Germany EMB oil tube connector

√ Germany Siemens main motor

√ France Schneider Electrics

√ Hydraulic and electrical overload protection

√ Upper are mechanical fast pinching dies. Lower are double-V replaceable dies

3. Safety Standard:

● 1.EN 12622:2009 + A1:2013 2.EN ISO 12100:2010 3.EN 60204-1:2006+A1:2009

● Front protection device for protecting finger ( safe light curtain )

● South Korea KACON Pedal switch ( 4 safety grade )

● Rear metal safeguards and CE standard

● Safety relay monitors completed with pedal switch, safety protection

● Safety standards(2006/42/EC)

Detailed Images

Technical Parameters

Model | WC67Y- 30T/1600 |

Nominal force | 300KN |

Worktable length | 1600mm |

Poles distance | 1200mm |

Throat depth | 200mm |

Stroke | 100mm |

Max open | 300mm |

Power | 5.5KW |

Dimension | 1600*900*1600mm |

Wight | 1600kg |

Company Introduction

Nanjing Bosslaser CNC Technology Co., Ltd. Boslaser is a famous brand company in China, which is dedicated to development, production and sales of sheet metal equipment. Located in Nanjing, Jiangsu Province, After 15 years development, it has been a famous and influential modern enterprise which owns two Subsidiary corporations - Maanshan Durmapress Machinery Technology Co., Ltd and Nanjing Bosslaser CNC Technology Co.,Ltd .

Adhering to the advanced European design concept, Boslaser follow the technology of Belgian R&D center, combine with the actual needs of customers, and make well-structured and high-quality sheet metal fabrication equipment. Most importantly, it makes us be the professional sheet metal processing equipment supplier.

Adhering to the advanced European design concept, Boslaser follow the technology of Belgian R&D center, combine with the actual needs of customers, and make well-structured and high-quality sheet metal fabrication equipment. Most importantly, it makes us be the professional sheet metal processing equipment supplier.

Certification

Packing & Delivery

FAQ