Металлический папка изгиба Бендер машина для формовки NOKA 250 тонны 4 оси гидравлического CNC листовой металл гибочная пресс

- Категория: Metal Sheeting Processing Machines >>>

- Поставщик: Noka,Machine,(anhui),Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 10710.50 $* | 11246.1 $* |

| Aug-15-2025 | 10620.69 $* | 11151.53 $* |

| Jul-15-2025 | 8910.98 $* | 9356.79 $* |

| Jun-15-2025 | 10440.25 $* | 10962.97 $* |

| May-15-2025 | 9090.33 $* | 9545.63 $* |

| Apr-15-2025 | 10260.41 $* | 10773.22 $* |

| Mar-15-2025 | 10170.91 $* | 10679.7 $* |

| Feb-15-2025 | 10080.16 $* | 10584.19 $* |

| Jan-15-2025 | 9990.3 $* | 10490.72 $* |

Характеристики

Product Description

A press brake is a machine tool for bending sheet and plate material, most commonly sheet metal. It forms predetermined bends by clamping the workpiece between a matching punch and die.

Backgauge Control Axis Description

The correct back gauge for the application can have a substantial positive influence on production part volume and accuracy. The more intricate the parts, typically the more axes on the back gauge you should have. Volume of parts needs to be considered also. A smart, experienced brake press op- erator can bend, form and produce some very intricate parts without even a single axis back gauge. However, the more time it takes to form the correct part, the more costs you have in the part. So the best scenario would be to have an experienced operator with the correct back gauge system that will magnify their skills. But in today's market, smart, experienced Press Brake operators are getting hard to find. So the correct back gauge for the application will decrease costs per part by helping to make a good press operator, a great one. The less experience an operator is the more axes you should have. Also, experienced operators know the benefit of correct backgauge for applications.

More Models, Please Refer To The Technical Data Sheet

Operating Systems Can Selected

Numerical control system can be divided into digital control and computer digital control. In the numerical control system of the bending machine, digital control generally means that the user cannot modify the programmed program. Computer digital control means that the user can edit the program by himself and modify the program according to the actual operation requirements. Compared with the digital control system, the computer digital control system is more convenient.

Description Of Application Effect

WE67K/WC67K Series Cnc Press Brake Machine Is Suitable For Various Fields Of Sheet Metal Processing. Different Molds Can Be Selected. Through Programming In The Operating System, Various Shapes Of Product Bending Can Be Realized.

Detailed Images

Electrical Cabinet

The Distribution Box Has A Scientific Design And A Heat Sink. With Ground Protection. Standard Schneider Electric And Omron Power Switch Safe And Efficient

Metal Fence

The Machine Is Equipped With Metal Guardrails As Standard, Which Is Safe And Beautiful. It Guarantees The Quality Of The Machine And Gives The Worker The Protection As Much As Possible.

Four-level Stop Finger

The Four-level Stop Finger Refers To The More Extensive Use,Using 2, 3, 4-level Stoppers Refers Can Play A Supporting Role In Thin Sheet Metal Workpiece.

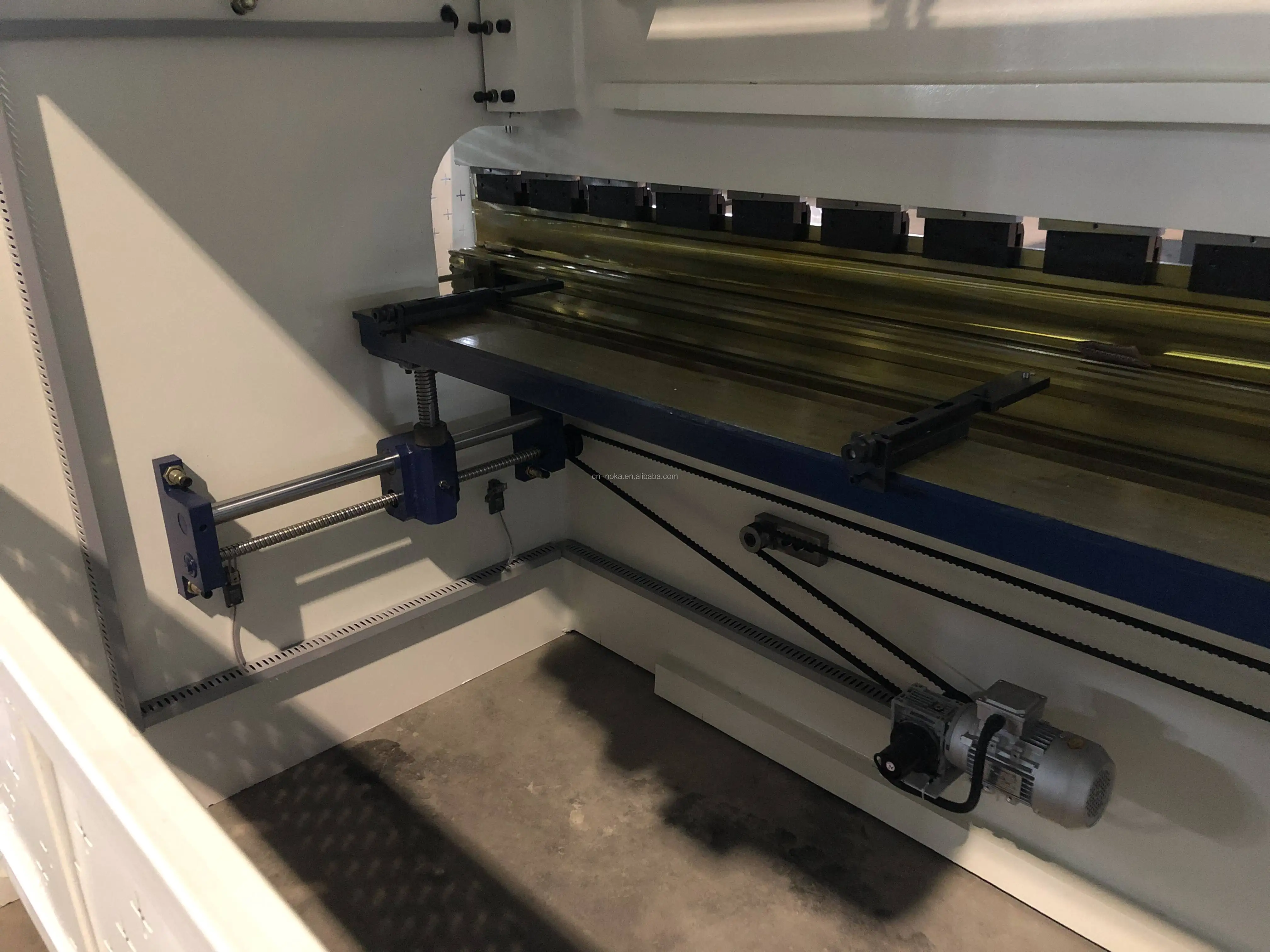

Automatic Axis

The Choice Of Automatic Axis Can Greatly Improve The Precision Of Machining, And The Combination Of X, Y, Z And V Axes Can Be Used To Form Different Combinations Of 3+1 Axis, 4+1 Axis, 6+1 Axis, Etc.

Main Motor From Siemens

Siemens motors ensure continuous and long-term reliable operation of key components. The heat dissipation ribs are horizontally and vertically distributed: all motors are designed with IP55 protection and are customized according to Siemens requirements. Excellent rotor processing technology, high surface blasting finish

Hydraulic Oil Pump from SUNNY

1. The ability to achieve high working pressure in a compact form factor ensures high power-to-weight ratio and reduced installation costs.

2. The inherent low noise characteristics of the daughter blade mechanism improve operator comfort.

3.12 The blade system ensures that the amplitude of the flow pulsation is small and the system noise characteristics are low.

2. The inherent low noise characteristics of the daughter blade mechanism improve operator comfort.

3.12 The blade system ensures that the amplitude of the flow pulsation is small and the system noise characteristics are low.

Hydraulic Valve From RexRoth

Rexroth oil pump has slotted control swashplate design, continuously variable displacement, good self-priming, allowing continuous working pressure of 350 bar, low noise, long service life, drive shaft can absorb axial and radial loads, modular Design, through-axis drive control time is short, pump position is optional, installation position can also be selected, can work with HFC liquid under reduced operating parameters.

NOK Seal

NOK seals are used in the reciprocating motion of hydraulic, air pressure and hydraulic machines. The seal made of NOK material surpasses the performance of the previous products. The sealing product series developed on the basis of this material greatly improves the sealing reliability of industrial machines.

Steel Plate Thickness

The machine's high-strength steel plate structure is very strong, the average steel plate thickness reaches the width of 4 adult fingers, about 65mm, so the machine's structural performance is perfect, the thickness of the steel plate can be comparable to armored vehicles and tanks.

Laser Protector

The laser protector protects the safety of the worker to the greatest extent. If the foreign object is detected and the working range of the machine is detected, the machine will stop working immediately, and the humanized design has won the praise of the customer.

Related Products

Packing&Shipping

Before the machine is shipped, the mould will be coated with antirust oil. Special and effective packing. The machine is

transported by standard container, and the common ones are 40 OT / 20 OT / 40 HQ / 40 GP / 20 GP. Inside the container, there will

be more wire rope and multiple angle fixing machines.

We will also make videos to let you know how the equipment is loaded into the container.

Please contact our sales consultant for the best shipping plan and accurate quotation

transported by standard container, and the common ones are 40 OT / 20 OT / 40 HQ / 40 GP / 20 GP. Inside the container, there will

be more wire rope and multiple angle fixing machines.

We will also make videos to let you know how the equipment is loaded into the container.

Please contact our sales consultant for the best shipping plan and accurate quotation

After Sales Service

After-sale Protection

1--Provide detailed operation and installation files and videos with the machine.

2--Free training for customers in the factory.

3--Engineers and sales consultants 24 hours online video with you, troubleshooting machine.

4-- Replace the problem accessories for you free of charge during the warranty period.

5-- The dealer goes to repair .

6-- The engineer goes to serve.

2--Free training for customers in the factory.

3--Engineers and sales consultants 24 hours online video with you, troubleshooting machine.

4-- Replace the problem accessories for you free of charge during the warranty period.

5-- The dealer goes to repair .

6-- The engineer goes to serve.

Company Introduction

Anhui NOKA Machinery Manufacturing Co., Ltd. was established in 1994, located in the ancient capital of Nanjing, the steel city Maanshan junction point to see a lot of industrial parks.

The company specializes in CNC machine tools, forging machinery, mechanical blade molds, mechanical parts, mechanical presses,

hydraulic presses, hydraulic presses, ironwork, mechanical bending and so on.

Here, NOKA has a long and strong engineering experience, and hopes to become a quality-oriented professional machinery

manufacturing company that serves the industry.

The company specializes in CNC machine tools, forging machinery, mechanical blade molds, mechanical parts, mechanical presses,

hydraulic presses, hydraulic presses, ironwork, mechanical bending and so on.

Here, NOKA has a long and strong engineering experience, and hopes to become a quality-oriented professional machinery

manufacturing company that serves the industry.

Customer Photos

Recommend Products