Почти новый гидравлический листогибочный станок с ЧПУ для листового

- Категория: >>>

- Поставщик: Nanjing,Chiming,Machinery,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 11900.79 $* | 12495.49 $* |

| Aug-15-2025 | 11800.53 $* | 12390.54 $* |

| Jul-15-2025 | 9900.93 $* | 10395.39 $* |

| Jun-15-2025 | 11600.80 $* | 12180.91 $* |

| May-15-2025 | 10100.54 $* | 10605.46 $* |

| Apr-15-2025 | 11400.16 $* | 11970.97 $* |

| Mar-15-2025 | 11300.6 $* | 11865.35 $* |

| Feb-15-2025 | 11200.19 $* | 11760.72 $* |

| Jan-15-2025 | 11100.55 $* | 11655.66 $* |

Характеристики

Products Description

Product parameters

Model | Nominal pressure(KN) | Length of table(mm) | Distance between columns(mm) | Throat depth(mm) | Stroke(mm) | Open height(mm) | Main motor(KW) | Overall dimensions L×W×H(mm) | ||||||||

63t/2500 | 630 | 2500 | 1905 | 300 | 150 | 420 | 5.5 | 2700*1700*2300 | ||||||||

63t/3200 | 630 | 3200 | 2700 | 300 | 150 | 420 | 5.5 | 3400*1700*2300 | ||||||||

80t/2500 | 800 | 2500 | 1900 | 300 | 150 | 420 | 5.5 | 2700*1700*2400 | ||||||||

80t/3200 | 800 | 3200 | 2700 | 300 | 150 | 420 | 5.5 | 3400*1700*2300 | ||||||||

100t/3200 | 1000 | 3200 | 2700 | 350 | 180 | 420 | 7.5 | 3400*1800*2600 | ||||||||

100t/4000 | 1000 | 4000 | 3100 | 350 | 180 | 420 | 7.5 | 4200*1800*2600 | ||||||||

125t/3200 | 1250 | 3200 | 2700 | 350 | 200 | 420 | 11 | 3400*1900*2600 | ||||||||

125t/4000 | 1250 | 4000 | 3090 | 350 | 200 | 420 | 11 | 4200*1900*2600 | ||||||||

160t/3200 | 1600 | 3200 | 2600 | 350 | 200 | 450 | 15 | 3400*2000*2800 | ||||||||

200t/3200 | 2000 | 3200 | 2600 | 400 | 200 | 450 | 18.5 | 3400*2200*2850 | ||||||||

250t/3200 | 2500 | 3200 | 2600 | 400 | 250 | 520 | 22 | 3500*2100*3800 | ||||||||

300t/4000 | 3000 | 4000 | 3200 | 400 | 250 | 580 | 22 | 4300*2500*3900 | ||||||||

300t/6000 | 3000 | 6000 | 4600 | 400 | 250 | 580 | 22 | 6300*2500*4800 | ||||||||

400t/4000 | 4000 | 4000 | 3200 | 400 | 250 | 580 | 30 | 4200*2700*4200 | ||||||||

400t/6000 | 4000 | 6000 | 4600 | 400 | 250 | 600 | 30 | 6300*2700*4300 | ||||||||

500t/4000 | 5000 | 4000 | 3200 | 400 | 250 | 600 | 37 | 4300*2700*4200 | ||||||||

500t/6000 | 5000 | 6000 | 5050 | 400 | 300 | 600 | 37 | 3600*3300*4800 | ||||||||

600t/5000 | 6000 | 5000 | 3800 | 500 | 320 | 640 | 45 | 5300*3300*4500 | ||||||||

700t/6000 | 7000 | 6000 | 4900 | 500 | 320 | 700 | 55 | 6300*3500*5500 | ||||||||

800t/6000 | 8000 | 6000 | 4600 | 500 | 320 | 800 | 55 | 6300*3500*6000 | ||||||||

The above parameters and configuration is for reference only,specific configuration by mutual agreement shall prevail. | ||||||||||||||||

Characteristic:

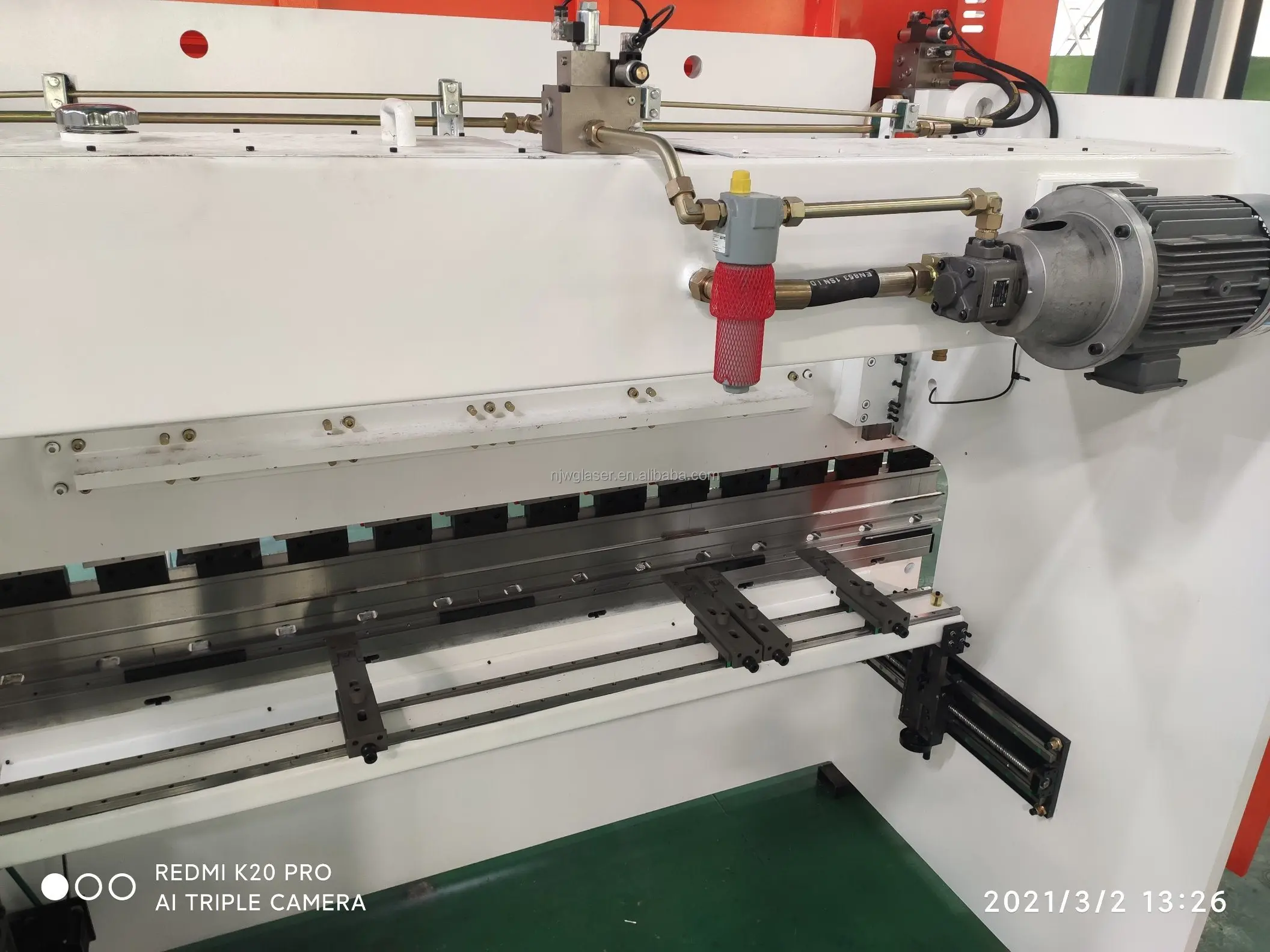

CNC Press Brake The CNC press brake uses the mold (general or special mold) to bend a cold metal sheet into a workpiece of various geometric cross-section shapes. It is a sheet metal forming machine designed for cold rolling sheet metal processing. It is widely used in sheet metal bending, such as automobile, aircraft manufacturing, light industry, shipbuilding, container, elevator, railway vehicles and other industries.

1. High bending precision,fast working speed, and efficient,operational safety,performance stably.

2. Good antiknock frame(welded-steel plate construction),whole frame is been tempering,reduce modification,using large-scale CNC milling machine,process in one time,insure high-precision.

3. Using international brand parts and cnc. 4. Visual operating system,easy operation,convenient,multi-functions and practical.

5. Power safeguard design,with light curtain protection,open door power-off function,more safety when operating.

6. All parts are produced by cnc produce center,according to standard drawing. 7. High executive force,high standard and high professional machine assembled team.

8.Replaceable worktable and the upper and lower mound,no welding,forging and precision grinding.

9. Fashion outlook,delicate,and beautiful,machines are compact design,small floor space,easy operation. 10. Providing comprehensive bending program for all press brake,shearing machine user.

11.In time fast delivery.

12.Thickening the slider and the vertical plate, to ensure the stability of the machine tool and reduce the elasticity.13.Rational layout of the oil pipeline design, to prevent the oil temperature rise quickly.

Why Choose Us

1. CE certified product and test machine with materials before delivery

CE certified products, Before leaving the factory, all machines must be debugged with materials to reach the normal trial

production status, and the goods can be delivered only after the customer's remote video acceptance .

2.Provide equipment drawings

We will provide electrical drawings, installation drawings for equipment placement, videos and documents for solving common machine failures, so as to facilitate customers' later installation and debugging.

3. Good after-sales service

In addition to providing equipment installation videos for customers, we will set up a service team for customers about

after-sales needs, including the company's manager, sales manager, engineers, customers and other relevant personnel, so that we can answer customers' any questions at any time. These online guidance services are completely free.

Company show

Chiming Machinery Co., Ltd. is an enterprise integrating R & D, design, production and sales. According to customer

requirements,the company selects the best technical scheme and equipment, establishes customer service archives, carries out after-sales tracking service, and ensures reliable quality, excellent performance and reasonable price to meet customer requirements. The products are exported to Southeast Asia and developed countries in Europe and America.

FAQ

1. Do you have it in stock? We have standard size in stock.

2. How long do you make the order product? Common products for 7 days,

big qty and none standard products for 15-25 days.

big qty and none standard products for 15-25 days.

3. How about the quality? We have export to many other customers from all over

the world, the feed back is good,quality is the first of our company.

the world, the feed back is good,quality is the first of our company.

4. Could you do OEM? Yes, of course. We can produce

according customers' requirement, just send us your requirements and design of drawing and sample.

according customers' requirement, just send us your requirements and design of drawing and sample.

5. Delivery? 1-2 units we could

send by EXPRESS(DHL, UPS, FEDEX, TNT, EMS), heavy weight more than 50kg,we suggest to use sea freight CIF or by air. 6. Q:How do your factory carry out quality control?

send by EXPRESS(DHL, UPS, FEDEX, TNT, EMS), heavy weight more than 50kg,we suggest to use sea freight CIF or by air. 6. Q:How do your factory carry out quality control?

A:Skillful workers take care of every details through production to packing.