WD67K-125T/2500 Delem DA66T system 6 + 1 axis электро-гидравлический сервопривод CNC листогибочный

- Категория: Оборудование для обработки металлических листов >>>

- Поставщик: Anhui,HuaXia,Machine,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 41055.91 $* | 43108.92 $* |

| Aug-15-2025 | 40710.98 $* | 42746.17 $* |

| Jul-15-2025 | 34155.67 $* | 35863.47 $* |

| Jun-15-2025 | 40020.98 $* | 42021.63 $* |

| May-15-2025 | 34845.49 $* | 36587.24 $* |

| Apr-15-2025 | 39330.96 $* | 41297.85 $* |

| Mar-15-2025 | 38985.4 $* | 40934.17 $* |

| Feb-15-2025 | 38640.32 $* | 40572.65 $* |

| Jan-15-2025 | 38295.67 $* | 40210.9 $* |

Характеристики

Product Description

electro hydraulic servo CNC press brake machine | ||||||

FEATURES: |

1.Totally EU streamlined design,Monoblock by welding robots & aparatus and stress relief process by Annealing treatment. |

2. Adopt integrated hydraulic system, more reliable and easy for maintenance and the hydraulic system from Bosch-Rexroth,Germany. |

6 + 1 axis: Y1 and Y2 for Oil cylinder stroke, X and R for back gauge , Z1 and Z2 for stoppers, V for Hydraulic compensation. |

4. The stroke and distance of the back gauge is adjusted by the motor and is well adjusted by hand, the adjustment is displayed by DA66T. |

5. Inch, single mode being designed for the machine and reversing and maintain time can be controlled by the time relays. |

6. Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety |

Technical analysis

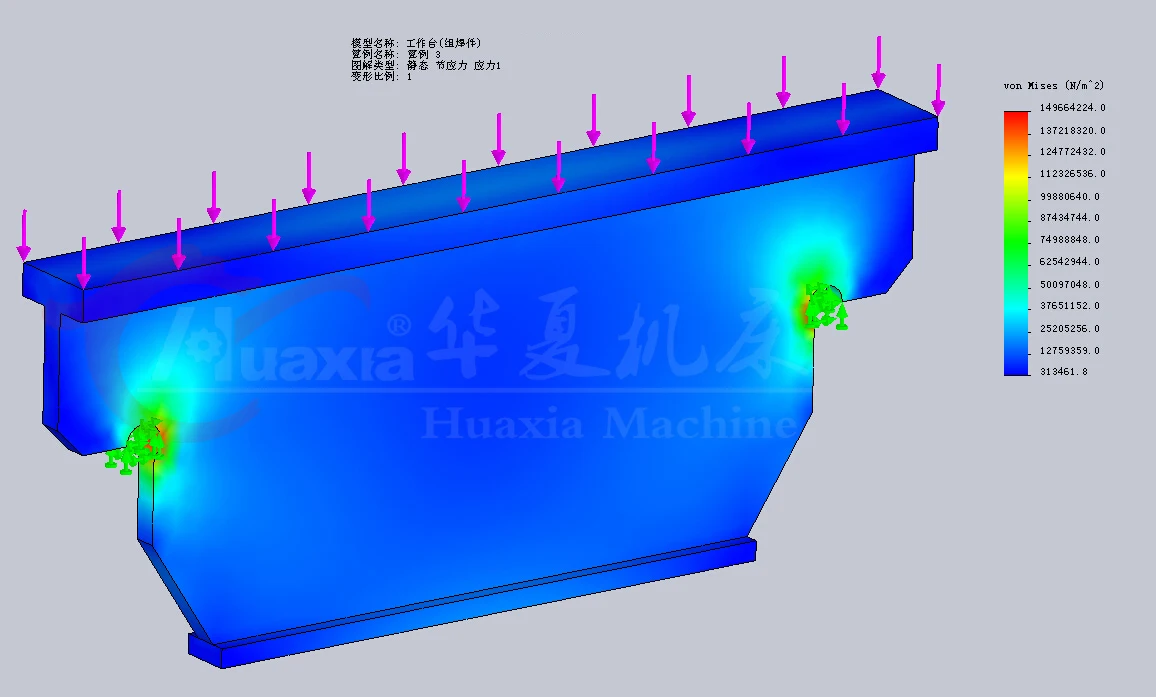

RIGID FRAME CONSTRUCTION & DUAL HYDRAULIC CYLINDERS

The machine body is in an overall welded and overall processed structure, and ANSYS finlte element analysis software is appplied to main parts of the machine body for analysis, which has ensured the reliability of machine and the precision of entire machine.

CROWNING SYSTEM |

Manual and CNC crowning ensures a constant bend angle across the full length of the machine This is achieved by pre loading the machine, to off-set any possible deflection under load or compensate for any tool wear, so that under load contacting surfaces are parallel to each other. With CNC crowning systems the press brake control is preprogrammed with machine characteristics and deflection data. With manual crowning a simple spread sheet or chart can be easily developed for each application. |

Technical Parameters

ITEM | UNIT | WD67K-125T/2500 |

system | CNC | DA66T |

nominal pressure | kN | 1250 |

workbench length | mm | 2500 |

workbench width | mm | 180 |

poles distance | mm | 1900 |

throat depth | mm | 320 |

slider stroke | mm | 120 |

max opening height | mm | 380 |

slider stroke adjust length | mm | 100 |

main motor | kW | 7.5 |

dimension(length*width*height) | mm | 2600*1750*2520 |

Detailed Images

Features of CNC system:

DA-66T

•2D graphical touch screen programming mode

•3D visualisation in simulation and production

•17" high resolution colour TFT

• Full Windows application suite

•Delem Modusys compatibility (module scalability and adaptivity)

• USB, peripheral interfacing

• Open system architecture

• Sensor bending & correction interface

•3D visualisation in simulation and production

•17" high resolution colour TFT

• Full Windows application suite

•Delem Modusys compatibility (module scalability and adaptivity)

• USB, peripheral interfacing

• Open system architecture

• Sensor bending & correction interface

MACHINE AXIS |

6 + 1 axis: V for Hydraulic compensation. Y1, Y2,for Oil cylinder stroke; X and R for back gauge ; Z1,Z2 for stoppers. |

Table compensation device----

Villa workbench ( V axis)

Villa workbench ( V axis)

The V axis is the axis of CNC control table and convex amount, can obtain the deflection compensation precise on the working table length. With convex wedge convex table by a group with an inclined plane each with convex wedge slope deflection curve designed according to the sliding work table vertical plate, finite element analysis and. CNC system according to the load force of the workpiece bending size (the force causes the slider and the work table vertical plate deflection deformationi), compensation calculation required, automatic control and relative displacement of convex wedge block, so as to effectively compensate the deflection slider and table upright plate deformation, bending workpiece can get the ideal.

BACKGAUGE AXIS:

X axis: control the bacguage move ---front to back

R axis: control the bacguage move ----up and down

Z1,Z2 axis :control the bacguage move---up and down

Configuration: |

Our factory

India exhibition in New Dehli.

Certifications

Packing & Delivery

Our Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.