Станок для выпрямления и резки стальных стержней по заводской цене высокоскоростная

- Категория: Other Construction Machinery >>>

- Поставщик: Chengdu,Gute,Machinery,Works,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-16-2025 | 131982.28 $* | 134622.20 $* |

| Jul-16-2025 | 107041.59 $* | 109182.41 $* |

| Jun-16-2025 | 129904.75 $* | 132502.37 $* |

| May-16-2025 | 128865.93 $* | 131442.33 $* |

| Apr-16-2025 | 102884.37 $* | 104942.63 $* |

| Mar-16-2025 | 126786.57 $* | 129322.36 $* |

| Feb-16-2025 | 125747.68 $* | 128262.45 $* |

| Jan-16-2025 | 124708.37 $* | 127202.15 $* |

Характеристики

Numerical Control Steel Bar Straightening and Cutting Machine SGT5-12

Specifications of Common Accessories

Description | Model & Specs | Quantity | |

Hydraulic accessories | Gear pump | CBN-F314G/ Flat shaft /Left turning | 1 |

Solenoid valve | 4WE6G-220V | 1 | |

Pressure regulating valve | DG-02-22H | 1 | |

63×51×14 | 1 for each | ||

Lower oil seal of cylinder | 40×48×10 | 1 | |

Dust ring of cylinder | 40×48×6.5/5 | 1 | |

O-ring of solenoid valve and pressure regulating valve | Φ12.5×1.9 | 4 | |

O-ring of cylinder | 63×3.5 | 2 | |

Electric parts | Transformer | BK-50VA | 1 |

AC contactor | 1218-220v | 2 | |

Power switch | D47-63 25A3P | 1 | |

Bearing | Straitening wheel, lower pinch wheel | 6201 | 18 |

Straightening frame | VCP210 | 2 | |

Electronic ruler | 6201 | 2 | |

Cutter trolley | 6204 | 4 | |

I. General

Welcome to use GUTE products,

“GUTE” Automatic NC Hydraulic Bar Straightening Cutter is known for its experience, efficiency and satisfaction.

What is your expectation for a type of highly-efficient machine?We think it should be reliable, powerful, user-friendly and conforming to engineering technology. Your expectation is also our goal. We aim to provide user-friendly machines for our customers!

Efficiency means to avoid unnecessary work and wasting of time, whether in preparation or in work. High-efficient machine helps you to enhance competitiveness and profitability. This is why we provide our machine with advanced technical solutions and well-deliberated design of hydraulic-pressure system details.

Before being launched on the market, each of our products has to accept thorough test in strict standards. Our expertise and strong R&D capability enable us to gain an advantage over our competitors, offer you more efficient products and more professional service.

Tips

To ensure your personal safety and normal operation of machine, please read this manual before installation and in regular maintenance and have a good understanding of knowledge about the machine, safety warning and tips. Improper operation may cause personal injury and damage of machine!

II. Performances & Features

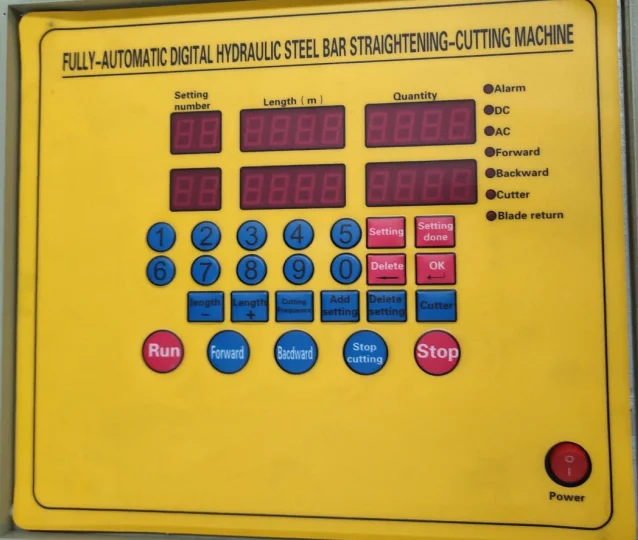

1. Micro-computer is used to control automatic straitening and hydraulic-pressure cutting of steel bar (round steel and deformed steel).

2. Intellectual operation system, anyone who knows “123” is able to operate the system (The operator shall read and understand the manual before operation).

3. Hydraulic system is of standard design and free of frequent repair.

4. Photoelectric coded ruler with more accurate length.

5. It is able to assign task orders in multiple batches, computer-assisted memory, high efficiency and convenience.

6. Remote-control shut-down within 30m.

7. The machine runs with stable operation, low fault rate and is free of frequent repair.

III. Major Parameters

1. Diameter of steel bar cut by GT4-10 Straightening Cutter: round steel: φ4-φ10mm, deformed steel: φ4-φ8mm;

Diameter of steel bar cut by GT5-12 Straightening Cutter: round steel: φ4-φ12mm, deformed steel: φ4-φ10mm;

2. Length range of steel bar cut by Straightening Cutter: 0.5-99mm

3. Straightening linear speed: 35m/min~5m/min

4. Output of each shift (based on 8 hours); φ6(3-4tons); φ8(4-6tons); φ10(8-10 tons) φ12 (10-12tons)

5. Number of batch of task orders input at the same time: 1-20 batches, number of task orders inserted: 1-20 batches

6. Number of steel bar cut in single batch: 1-9999

7. Normal length error: ±8mm for round steel

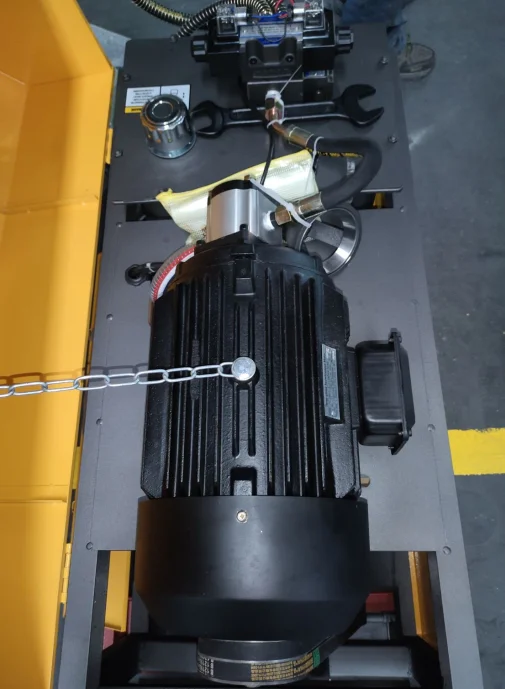

8. Power: three-phase AC 380V/50HZ

10. Power of motor (conform to national standard): 4kW-4 for type GT4-10/4kW-4; 5.5kW-4 for type GT5-12

11. Power of NC box: ≤15W

12. Size of main machine: 1300mm (L) ×530mm (W) ×830mm (H)

13. Weight of the whole machine: type GT4-10/230kg; type GT5-12/248kg