Rbqlty гидравлический листогибочный станок с ЧПУ полностью Автоматический

- Категория: Metal Sheeting Processing Machines >>>

- Поставщик: Anhui,Runbang,Heavy,Industry,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 660767.82 $* | 673982.32 $* |

| Jul-19-2025 | 535898.35 $* | 546616.59 $* |

| Jun-19-2025 | 650361.55 $* | 663368.56 $* |

| May-19-2025 | 645158.18 $* | 658061.9 $* |

| Apr-19-2025 | 515086.16 $* | 525388.46 $* |

| Mar-19-2025 | 634753.59 $* | 647448.29 $* |

| Feb-19-2025 | 629550.42 $* | 642141.22 $* |

| Jan-19-2025 | 624347.84 $* | 636834.39 $* |

Характеристики

Rbqlty hydraulic press brake cnc folding machine full automatic servo motor

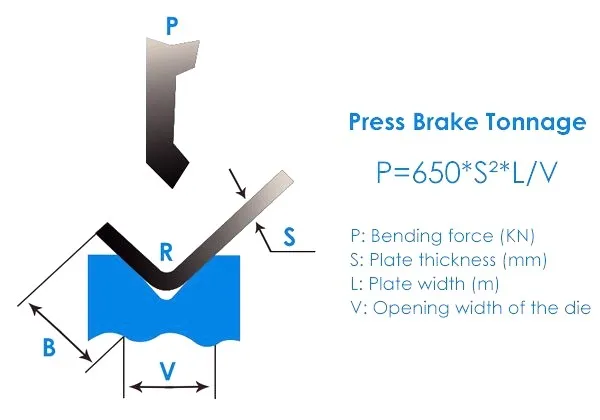

Basic parameters, such as the force or tonnage and the working length.Additional parameters include the stroke length, the distance between the frame uprights or side housings, back gauge distance, and work height.

Whole structure:

1.Machine body adopts intergrated welded structure.the main parts of the machine was analyzed by ANSYS finite element analysis software,which ensures the reliability of the machine and the precision of the entire machine;

2.The main oil cylinders fitted on both sides adopt closed loop control mode which is composed of Germany electro-hydraulic servo valve and imported grating ruler,breaking through the stroke control mode of traditional mechanical stop bending machines, ensuring the high precision of the glide position, the accurate and stable operation, the high precision of bending, and high precision of the repeated positioning of slider;

3.The functional components of the back gauge are all imported, ensuring the stopping precision.The machine also can adopt more functional multi-axis blocking according to the customers' requirements;

4.The hydraulic system adopts integrated control system imported from Germany, which decreases the installation of pipelines and ensures working stability of the machine too! and conciseness and beauty in appearance;

5.C-shaped plates are fitted on both sides of the machine body, and the high precision grating ruler is fitted on the C-shaped plate. Thus to avoid the influences on bending precision arising from distortion of machine body during bending process;

6.The lower workbench is fitted with hydraulic automatic deflection compen- sation mechanism, ensuring effective compensation without blind area and high precision of bending, so that long stability is guaranteed.

Payment Method | ||||

T/T | FOB | 30% T/T in advance, the balance paid before shipping | ||

CRF | 30% T/T in advance, paid the balance against copy of B/L | |||

CIF | ||||

L/C | L/C at sight or L/C 30 days is also accepted | |||

D/P | D/P is available for long-term cooperated customer | |||

Lead time | Normally 7-15 days after deposit or L/C received | |||

Trade Assurance Payment

100% product quality protection

100% on-time shipment protection

100% payment amount protection

Packaging & Delivery

Shipping Fee depends on size and weight

Plastic Film/wooden box/customized package

Full container load or less container load

Anhui Runbang Heavy Industry Machinery Co.,Ltd

We make sheet metal processing machine like bending machine, shearing machine, iron worker, hydraulic press, punching machine, duct manufacturing auto line, cutting machine and so on

Expert Team

With an expert team in R&D for more than 20 years, occupied the work shop of over 30,000 square meters, Runbang is able to support you with best quality machines.

Service Terms

1. Lifetime service, test before shipment

2. Online video and voice instruction

3. Online or Oversea Installation service

4. Online or Oversea Training service

5. 1 year warranty, free machine parts replacement

6. 100% response rate within 12 hours.

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com