Магнитный поплавковый байпас черный индикатор уровня резервуара для воды

- Категория: Measuring & Gauging Tools >>>

- Поставщик: Vacorda,Instruments,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 224.20 $* | 235.0 $* |

| Aug-17-2025 | 222.60 $* | 233.22 $* |

| Jul-17-2025 | 186.72 $* | 195.91 $* |

| Jun-17-2025 | 218.60 $* | 229.46 $* |

| May-17-2025 | 190.6 $* | 200.78 $* |

| Apr-17-2025 | 214.71 $* | 225.46 $* |

| Mar-17-2025 | 212.25 $* | 223.49 $* |

| Feb-17-2025 | 211.78 $* | 222.14 $* |

| Jan-17-2025 | 209.86 $* | 219.79 $* |

Характеристики

Magnetic Float Bypass Black Water Tank Level Indicator With Sensor

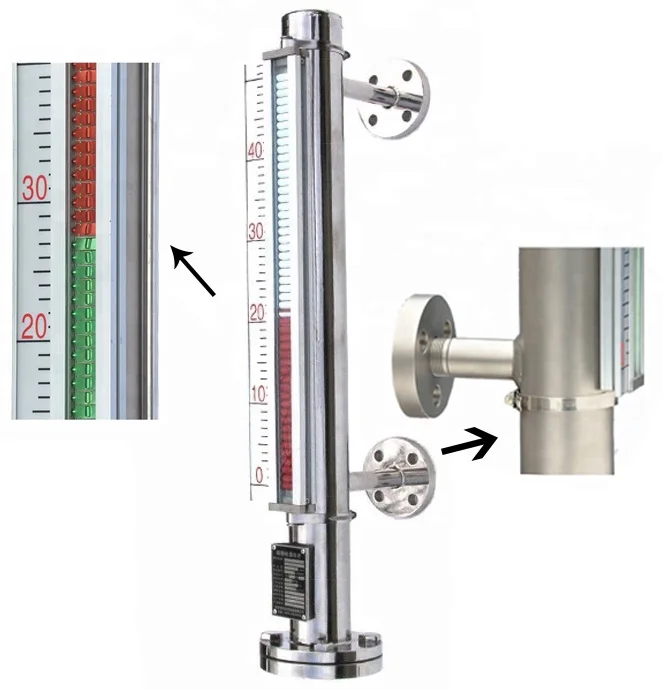

The UHC type magnetic column liquid level gauge is made up of measuring body,double colored display cylinder, ruler, magnetic float and level sensor(4-20mA output). Based on buoyance principle, the magnetic ball in the body of the level gauge is up or down with the liquid level changing and makes dual-colored turning to show the level of medium. Each cylinder is with two-color axisymmetric structures. The distance of two cylinders is 10mm. Red side of display cylinder indicates liquid and white side display cylinder indicates air. Besides measuring liquid level, it also could measure the interface level of the two kinds of liquid.

Advantages

1. High precision sied-mounted magnetic level liquid level gauge has simple structure, good stability and reliability.

2. Independent of medium’s physical and chemical states such as conductivity, dielectric constants, foam etc.

3. Appliable for all kinds of medium environment such as corrosive, toxic and explosive one.

4. Interface measurement or level measurement of 2 kinds of medium with different density.

5. Two-wire 4~20mADC signal output, 0.8’’ or 0.56” LED digital display of intelligent digital side-mounted magnetic level gauge

Intelligent digital side-mounted magneticflap liquid level gauge is widely used in petroleum, chemical industry, oil field, pharmaceuticals industry, food, wine industry etc., suitable for level measurements under the environment of high/low temperature, high pressure, strong corrosion, toxicity.

The magnetic flap level gauge can be directly used to observe the liquid level of media in various containers. It is suitable for liquid level indication in petroleum, chemical and other industrial fields. The liquid level gauge has the advantages of simple structure, intuitive and clear observation, no blockage and leakage, convenient installation and simple maintenance. The upper and lower flanges of the glass plate level gauge are connected with the container to form a connector. The actual height of the liquid level in the container can be directly observed through the glass plate. The upper and lower valves are equipped with safety steel balls. When the glass is accidentally damaged, the steel balls will automatically seal under the action of internal pressure in the container to prevent liquid overflow in the container and ensure the safety of operators.

Product features

1. Simple structure, good stability and reliability.

2. Independent of medium’s physical and chemical states such as conductivity, dielectric constants, foam etc.

3. Appliable for all kinds of medium environment such as corrosive, toxic and explosive working condition.

4. Interface measurement or level measurement.

5. Two-wire 4~20mADC signal output, 0.8’’ or 0.56” LED digital display.

Product Parameters

(1) Center-center distance: | 150~6000mm |

(2) Medium density: | More than 0.45g/cm3 |

(3) Nominal pressure: | PN2.5~PN40, PN40~PN320(x 0.1MPa) |

(4) Material: | SS304, SS316L, PP, SS304+PTFE, or customized |

(5)Operating temperature: | -190 ~ +425 °C |

(6) Process connection: | DN20~DN80/RF/14,DN80~DN250/RF/14 |

(7)Indicator types: | |

A: Al &ABS flap cylinder | B: Al flap plate |

C: PVC ABS flap cylinder | D: PP&ABS flap cylinder |

E: AL &LED | F: PP&LED |

(8) Structure of top chamber: | 1.Welding cap 2.Welding cap with M14*1.5 plug screw 3.Flange 4.Flange with M14*1.5 plug screw 5.Welding cap with DN20 flange 6.Flange with DN20 flange 7.Welding cap with air valve 8.Flange with air valve |

(9) Structure of bottom chamber: | 1.Flange cap 2.Flange with drain plug screw 3.Flange with DN20 welding tube 4.Flange with DN20 flange 5.Flange with needle/ball valve |

(10)Protection class: | IP65 |

(11)Application: Widely used in petroleum, chemical industry, oil field, pharmaceuticals industry, food, wine industry etc., suitable for level measurements under the environment of high/low temperature., high pressure, strong corrosion, toxicity. | |

Note: Basic type, top mounted type, heat tracing type, LPG specialized type, anti-corrosive type, boiler steam specialized type etc, they have some differences in technical parameter. Different pressure has different flange specification. | |

Installation

Sichuan VACORDA Instruments Manufacturing Co., Ltd.is a professional production-manufacturing enterprise specialized in designing, producing and marketing of instruments and apparatuses. Our company has been established for 23 years since 1997 to grow up to be a team of high-quality, united, hard-working and truth-seeking characters. Solid foundation has been established.

Our company has got the ISO9001: 2000 international quality system certification in 2005, Import and export trading right in 2012, total 12 patents till 2016, the title of “national high-tech enterprise” and CE certificate for three categories product in 2014. Our company has owned trade marks as “vacorda”. At the same time, our company is preparing for more certificates for foreign market, such as IECEX, API, UL and so on, to lay a foundation for further international market.

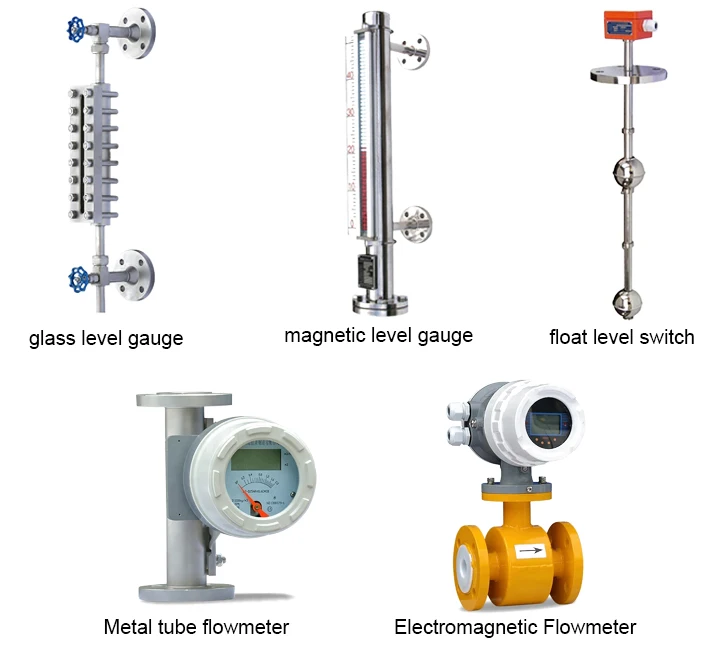

Our main products as follow

1. Magnetic level gauge, magnetic level switches, magnetic level controllers, bicolor quartz tube level gauge, boiler water level gauge and glass plate liquid level gauge, capacitance level gauge, ultrasonic level transmitter, radar level transmitter and liquid (material) level switch series;

2. Wedge-shaped flow meter, metal rota-meter, V Cone flow meter, throttling device, electromagnetic flow meter, vortex flowmeter, turbine flowmeter, ultrasonic flowmeter;

3. Pressure transmitter, differential pressure transmitter series;

4.Temperature transmitter, bimetallic thermometer, thermocouple, rtd series.

Q: The new magnetic flap liquid level gauge can't show liquid level?

A: 1.check whether there is block in by pass pipe 2.check the the density of medium 3.check whether the float ball is stucked by float ball.

Q: The longest length of magnetic flap liquide level gauge?

A: the length is customized,but in order to be convenient for transport,if the length is over 6m,we recommend

Q: If the float ball is installed at the wrong opposite direction,what's the influence?

A: reading level will be higher than true level,usually higher by length of floatball-70mm

Q: What's installation details of magnetic flap liquid level gauge ?

A: 1.before installation,check specification with label plate. 2.There shouldn't magnetic field within 400m

Q: There is problem in output signal 4--20mA?

A: 1.Check working power supply 2.check wiring 3,check load resistance 4.verify measuring range,zero point

Q: what's specification we need to know before purchasing magnetic flap liquid level gauge?

A: medium density,working temperature,working pressure,material,flange center to center distance,flange standard,whether need 4--20mA output signal;wether need level alarm