DPP-88 мини таблетки блистерной упаковочной машины в Китае (стандарты CE

- Категория: Машины для блистерной упаковки >>>

- Поставщик: Zhejiang,Leadtop,Pharmaceutical,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.97 $* | 0.22 $* |

| Aug-19-2025 | 0.7 $* | 0.26 $* |

| Jul-19-2025 | 0.74 $* | 0.8 $* |

| Jun-19-2025 | 0.45 $* | 0.99 $* |

| May-19-2025 | 0.37 $* | 0.31 $* |

| Apr-19-2025 | 0.90 $* | 0.41 $* |

| Mar-19-2025 | 0.20 $* | 0.49 $* |

| Feb-19-2025 | 0.72 $* | 0.39 $* |

| Jan-19-2025 | 0.46 $* | 0.18 $* |

Характеристики

Product Description

DPP-88 Automatic Blister Packing Machine is suitable for packaging of all kinds of liquid and solid in medium & small pharmaceutical factory, health medicine factory, hospital preparation lab, food industry, electronic industry, hardware industry, etc. It can protect the material from steam or dust, improve product packing degree, and increase the additional value.

The blister packing machine packing Tablet, Capsule, Soft Capsule, Jam, Oil, Sauce, Candy, Electronic-cigarette, Liquid, Ampoules, injection into aluminum plastic composite panel(ACP) or aluminum plate. The machine is used to produce small quality and many kinds of products.

Machine Data

Model | DPP-88 | DPP-140 | DPP-250 | ||

Blanking Frequency | 15-40/min | 5-50/min | 20-40/min | ||

Sheet’s quantity of one blanking | 1sheets | 1-4 | 1-4 | ||

Capacity | 900-2100sheets/hour | 300-12000 | 300-12000 | ||

Adjustable scope of feed travel | 10-110mm | 10-120 | 30-145 | ||

Max. Forming | 120*110*15mm | 160*120*25mm | 255 x 145 x 12mm | ||

Power Supply | 380V or 220V, 5.5kW, 50Hz, AC | 380V or 220V,5.5kW, 50Hz,AC 380V or 220V | |||

Wrapper Specification (PVC) | 120×(0.15-0.5)mm | ||||

Wrapper Specification (PTP) | 120*(0.02*0.035) mm | ||||

Overall Dimensions | 1650*500*1100mm | 2450*570*1550mm | 4200*650*1650mm | ||

Weight | 650Kg | 950Kg | 1500Kg | ||

Features

1.Travel scope can be adjusted. Mould is located by located groove so that it’s easy to change mould. The machine heats the PVC through conduction and forms it through pressing and frothing.

2.The material is fed automatically. The mould and feeding equipment can be designed as user’s requirements.

3.The heating moulds will automatically separate when the machine stops, which contributes to protect the material between them and extend the machine’s life.

4.The equipment of trace pressing, batch number printing and scrap-collecting can be chose.

5.Manipulator grip and tow wrapper, straight to-and-fro running, synchronize accurately and stably.

6.Speed is shifted by step-less transducer; the operation panel of PC cycle (can be Adopt interface of human-machine).

2.The material is fed automatically. The mould and feeding equipment can be designed as user’s requirements.

3.The heating moulds will automatically separate when the machine stops, which contributes to protect the material between them and extend the machine’s life.

4.The equipment of trace pressing, batch number printing and scrap-collecting can be chose.

5.Manipulator grip and tow wrapper, straight to-and-fro running, synchronize accurately and stably.

6.Speed is shifted by step-less transducer; the operation panel of PC cycle (can be Adopt interface of human-machine).

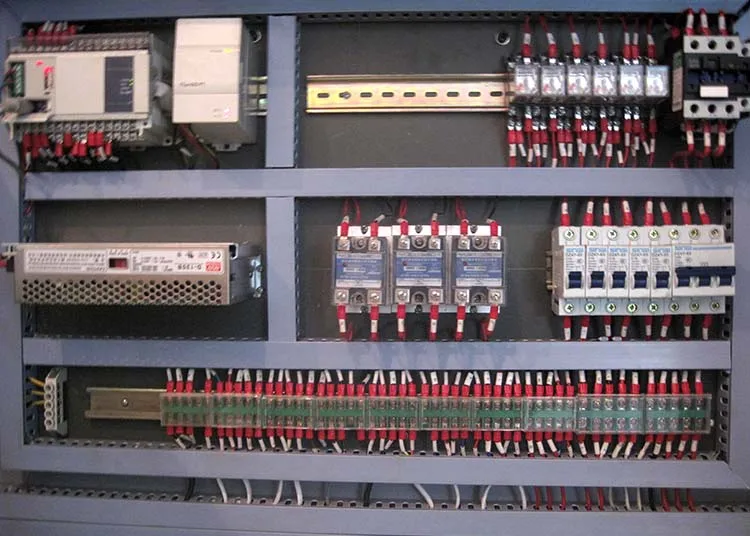

Details Images

Related Products

Company Introduction

Our Company

- Since year 1996, LTPM CHINA had started manufacturing Pharmaceutical and food packaging machines such as Capsule Filling Machine, Ampoule Filling and Sealing Machine, Blister Packaging Machine, Pill Counting and Bottling Line, Cartoning Machine, Bag Packaging Machine, Liquid Filling and Capping Machine etc.

- LTPM CHINA designs different types of packaging lines for customers, including standard or non-standard models.

- LTPM CHINA's machinery = High automation + High precision + More energy saving + Satisfactory warranty and after-sales service + Trusted brand

- LTPM CHINA designs different types of packaging lines for customers, including standard or non-standard models.

- LTPM CHINA's machinery = High automation + High precision + More energy saving + Satisfactory warranty and after-sales service + Trusted brand

Our Machinery Workshop

Our Certificates

ISO, CE, SGS, BV Certified Company.

Our Sales Team

Our Customers

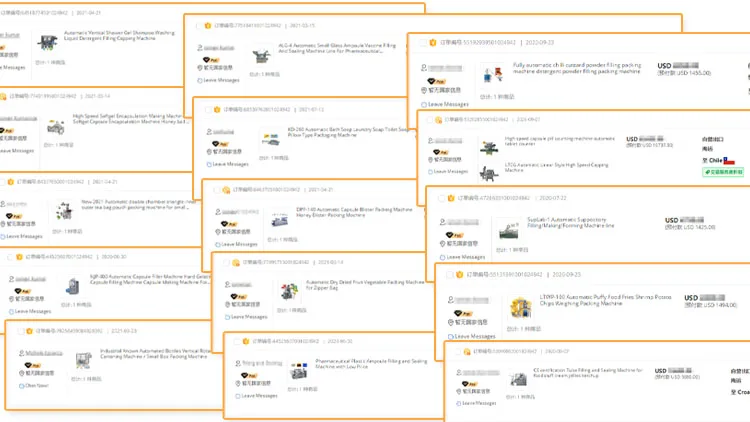

Orders from Alibaba

Packing & Shipping

All machine delivery with anti rust spray, film wrapping and Sea shiping affordable wooden box.

FAQ

Warm hint:

1 -- Because the exchange rate is changing, the specific price of the machine may also change.

2 -- Our machines can be customized according to your requirements, we also provide you with complete packaging line design services. Each of your products has its own optional solution.

3 -- Because of the time difference, online chat may not get a reply. Please click "contact supplier" or "send inquiry" to contact us.

2 -- Our machines can be customized according to your requirements, we also provide you with complete packaging line design services. Each of your products has its own optional solution.

3 -- Because of the time difference, online chat may not get a reply. Please click "contact supplier" or "send inquiry" to contact us.

Q1: What is Difference Between PLC Control and Real PLC Control?

A: PLC means programmable logic control. Such as, Blister packing machine, PLC Control change the old period in Blister Packing area. Nowadays, there are two PLC Control. One it is only used for controlling the touch screen, but when you adjust the traveling scope you need to adjust the mechanical wheel. Another is our Type, you can say PLC is my machine’s heart, you can enter everything into it to make the machine running.

Q2: How to Change Mould (Changing Parts)?

A:Nowadays we have improved our Mould changing parts, there is a groove and screw on the mould. If you want to change into different packing you can unscrew it then change. We call it convenient type mould. And we also get a video for changing mould.

Q3: When The Machine Stops, The Mould is Still Hot; Will It Heat PVC and Destroy Aluminum?

A:Our Forming Mould and Sealing mould will be separated automatically when the machine stops. It is special for protecting the unused material on the machine.

Q4: What is the Step Motor Using For?

A:We must know one thing, if you want the machine run and the material goes ahead. There must be a motor for towing. Normally saying, there are two types motor for towing the material. One is Pneumatic Clip (Air Clip), but when the machine stop the clip will loose and materials go back, you need to adjust the machine again when restart. So we adopt Step Motor, It will be never loose. And it makes the towing length unlimited if your forming mould is long enough.

Q5: The Machine Always Run Automatically, But When It Runs In a Wrong Length, What Should We Do?

A:According to this problem, we use a Camera Cell for registering the Color Point on Aluminum foil. When the machine run in a wrong length it will be found by Cameral Cell, then give a single to PLC, PLC will feedback to Step Motor, at last step motor will run in a right length to save material and time.

Q6: What Is The Warranty Period for Your Machine?

A: 5 years free warranty.

Q7: Do You Have Manual or Operation Video for Us To Know More About the Machine?

A: Yes, not only manual or operation video, 3D drawing also available to make as per your design,also the video we can make of testing the material from our packaging machine if your packing goods easier for us to find from our local market.

Q8: How Can I Trust You for The First Time Business ?

A: if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q9: Is Engineer Available to Serve Oversea?

A: Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine

installation and assist you till the end.

Q10: How Can We Make Sure About the Machine Quality After We Put the Order?

A: Before delivery, we will run the machine for half an hour - 1 hour to ensure that the machine is OK. And we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.

A: PLC means programmable logic control. Such as, Blister packing machine, PLC Control change the old period in Blister Packing area. Nowadays, there are two PLC Control. One it is only used for controlling the touch screen, but when you adjust the traveling scope you need to adjust the mechanical wheel. Another is our Type, you can say PLC is my machine’s heart, you can enter everything into it to make the machine running.

Q2: How to Change Mould (Changing Parts)?

A:Nowadays we have improved our Mould changing parts, there is a groove and screw on the mould. If you want to change into different packing you can unscrew it then change. We call it convenient type mould. And we also get a video for changing mould.

Q3: When The Machine Stops, The Mould is Still Hot; Will It Heat PVC and Destroy Aluminum?

A:Our Forming Mould and Sealing mould will be separated automatically when the machine stops. It is special for protecting the unused material on the machine.

Q4: What is the Step Motor Using For?

A:We must know one thing, if you want the machine run and the material goes ahead. There must be a motor for towing. Normally saying, there are two types motor for towing the material. One is Pneumatic Clip (Air Clip), but when the machine stop the clip will loose and materials go back, you need to adjust the machine again when restart. So we adopt Step Motor, It will be never loose. And it makes the towing length unlimited if your forming mould is long enough.

Q5: The Machine Always Run Automatically, But When It Runs In a Wrong Length, What Should We Do?

A:According to this problem, we use a Camera Cell for registering the Color Point on Aluminum foil. When the machine run in a wrong length it will be found by Cameral Cell, then give a single to PLC, PLC will feedback to Step Motor, at last step motor will run in a right length to save material and time.

Q6: What Is The Warranty Period for Your Machine?

A: 5 years free warranty.

Q7: Do You Have Manual or Operation Video for Us To Know More About the Machine?

A: Yes, not only manual or operation video, 3D drawing also available to make as per your design,also the video we can make of testing the material from our packaging machine if your packing goods easier for us to find from our local market.

Q8: How Can I Trust You for The First Time Business ?

A: if you don't trust us, then we can use Alibaba trade assurance service, guarantee your money, and guarantee your machine's on-time delivery and machine quality.

Q9: Is Engineer Available to Serve Oversea?

A: Yes, but the travel fee is paid by you. So actually to save your cost, we will send you a video of full details machine

installation and assist you till the end.

Q10: How Can We Make Sure About the Machine Quality After We Put the Order?

A: Before delivery, we will run the machine for half an hour - 1 hour to ensure that the machine is OK. And we will send you the pictures and videos for you to check the quality, and also you can arrange for quality checking by yourself or by your contacts in China.