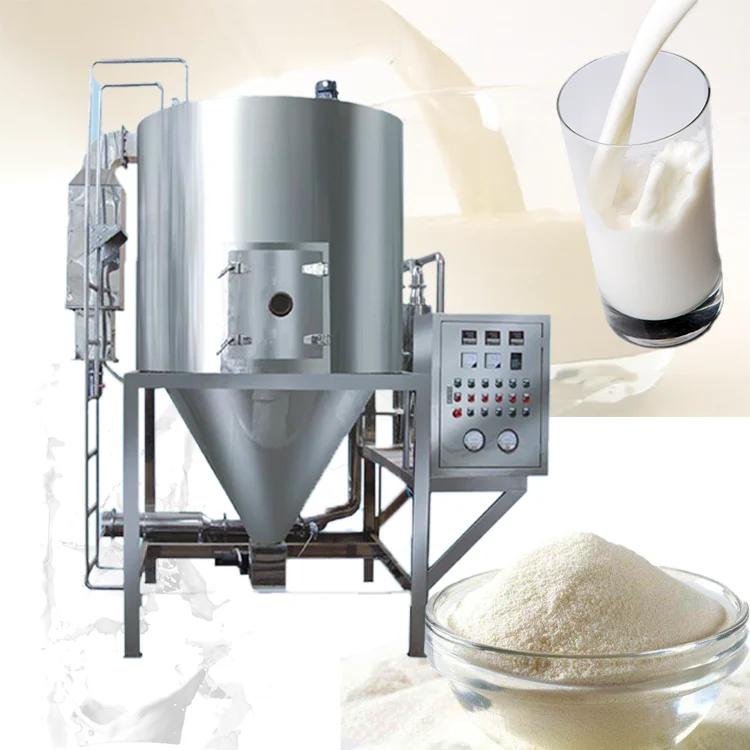

Сушильная машина для сухого молока модель сжиженного нефтяного газа высокоскоростная сушилка с

- Категория: Spray Drying Equipment >>>

- Поставщик: Zhengzhou,Great,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.15 $* | 0.5 $* |

| Aug-16-2025 | 0.87 $* | 0.94 $* |

| Jul-16-2025 | 0.59 $* | 0.81 $* |

| Jun-16-2025 | 0.26 $* | 0.99 $* |

| May-16-2025 | 0.67 $* | 0.19 $* |

| Apr-16-2025 | 0.55 $* | 0.56 $* |

| Mar-16-2025 | 0.33 $* | 0.34 $* |

| Feb-16-2025 | 0.68 $* | 0.6 $* |

| Jan-16-2025 | 0.20 $* | 0.87 $* |

Характеристики

Product Description

Spray drying equipment is widely used in liquid forming and drying industry.

Suitable for producing powder and granular solid products from solution, emulsion, suspension and paste liquid raw materials.

Therefore, when the shape of finished product must form a fixed standard, spray drying equipment can easily complete these works.

Model | Size(mm) | Tower body | Centrifugal spray atomizer | Materail | Heating Source | ||

GRT-SP-5 | 1600×1100×1750 | Φ1000mm | Φ50 mm | Electric Steam Gas Coal | |||

GRT-SP-25 | 4000×2700×4500 | Φ1750mm | Φ80 mm | ||||

GRT-SP-50 | 4500×2800×5500 | Φ2300mm | Φ120mm | ||||

GRT-SP-100 | 5200×3500×6700 | Φ2700mm | Φ150mm | ||||

GRT-SP-200 | 7500×6000×8000 | Φ3200mm | Φ150mm | ||||

GRT-SP-1000 | custom-made | ||||||

Working Principle

1.After fresh air is filtered and heated,it enters into the air distributor which on the top of the drier.The hot air in spiral form equably enters into the drying room.

2.When liquid raw material are passed through the high-speed centrifugal sprayer on the

top of the tower,it will be rotated and sprayed into the extreme slim mist liquid beads.

3.Raw material can be dried to the finalproducts instantly while it contact with heatedair.

4.Finished products are discharged continuously from bottom of the drying tower

and cyclones segregator.Wasted air is discharged from blower.

2.When liquid raw material are passed through the high-speed centrifugal sprayer on the

top of the tower,it will be rotated and sprayed into the extreme slim mist liquid beads.

3.Raw material can be dried to the finalproducts instantly while it contact with heatedair.

4.Finished products are discharged continuously from bottom of the drying tower

and cyclones segregator.Wasted air is discharged from blower.

Application Range

1.Food industry: milk powder, cocoa powder, milk substitutes, blood hunting powder, egg powder etc.

2.Food and plants: oats, chicken juice, coffee powder, instant tea, protein, peanut protein, hydrolysate, etc.

3.Sugars: corn syrup, corn starch, glucose, pectin, maltose, potassium sorbate, etc.

4.Plastic resin:Washing powder,AB, ABS emulsion,polyethylene, polyvinyl chloride, etc.

5.Ceramics: magnesium oxide, talcum powder, etc.

6.Chemical industry: basic dyes and pigments,catalysts, sulfuric acid, amino acids, white carbon black, etc.

2.Food and plants: oats, chicken juice, coffee powder, instant tea, protein, peanut protein, hydrolysate, etc.

3.Sugars: corn syrup, corn starch, glucose, pectin, maltose, potassium sorbate, etc.

4.Plastic resin:Washing powder,AB, ABS emulsion,polyethylene, polyvinyl chloride, etc.

5.Ceramics: magnesium oxide, talcum powder, etc.

6.Chemical industry: basic dyes and pigments,catalysts, sulfuric acid, amino acids, white carbon black, etc.

Product Features

1.Finished products have high quality and purity, good uniformity,good flow capability and solubility advantages.

2.Simple and stable operation,convenient control and debugging,easy to achieve automatic operation.

3.Drying speed is rapid.When liquid raw material is atomized,the surface of the material will be enlarged greatly.In the hot airflow 95% - 98% of water can be evaporated instantly.time of completing the drying is several seconds.This is especially adapt to dry heating sensitive material.

4.Process of production is simple,it is an ideal choice for liquid material which contains 40%-90% of water and want to dry it to powder once,this type of machine can reduce the procedure of smash and sieve,the operational environment is superior,always clean,and under healthful condition,it also can avoid powder flying while drying.

More Models

Company Profile

Zhengzhou Great Machinery Equipment Company Limited.is an enterprise of industry and trade with a collection of scientific researching,manufacturing,selling and serving more than 10 years' history .

It is not only an high-tech and modern enterprise which is specialized in agriculture equipment, fruit & vegetable processing equipment, different drying equipment, other food processing equipment,etc, but also one of the largest bases of technology research, development and practice of microwave energy application and hot air recycling.

FAQ

1.Are you manufacturer or trader? Where are your factory located?

We are manufacturer and we are located in Henan,China.and we can provide the competitive price and good quality.

5.How to transport equipmen?

We usually choose sea transportation. Laboratory models can be shipped by air according to customer requirements.

2.Can I use my own raw materials for extraction test?

Yes, of course. We can do extraction tests and send videos and test reports for your reference.

3.Do you have OEM service? Do you provide parts?

Yes, we will, as long as you provide us with your drawings and detailed requirements.

4.How can we visit your factory?

You can fly to Zhengzhou airport, or if you arrive in Shanghai, you can tell us your specific location. We will arrange a driver to pick you up.

5.How to transport equipmen?

We usually choose sea transportation. Laboratory models can be shipped by air according to customer requirements.