Zwsj серии High speed для перемотки и резки Джамбо-роллов бумажного комбината

- Категория: Paper Processing Machinery >>>

- Поставщик: Jinan,Chengdong,Machinery,Manufacture,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 53550.32 $* | 56228.25 $* |

| Aug-17-2025 | 53100.24 $* | 55755.50 $* |

| Jul-17-2025 | 44550.87 $* | 46778.30 $* |

| Jun-17-2025 | 52200.48 $* | 54810.15 $* |

| May-17-2025 | 45450.1 $* | 47723.46 $* |

| Apr-17-2025 | 51300.70 $* | 53865.42 $* |

| Mar-17-2025 | 50850.42 $* | 53393.91 $* |

| Feb-17-2025 | 50400.33 $* | 52920.88 $* |

| Jan-17-2025 | 49950.97 $* | 52448.97 $* |

Характеристики

Product Description

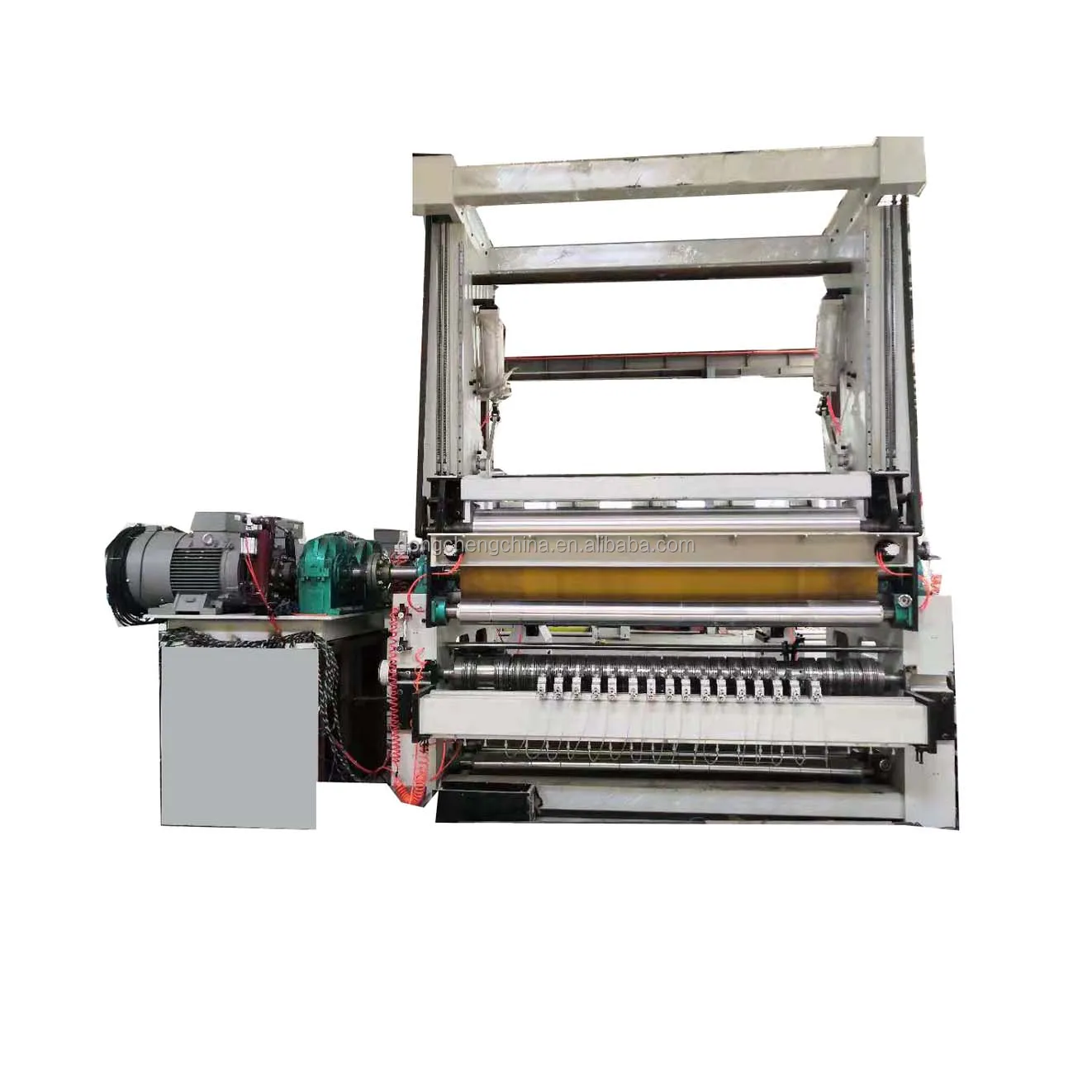

PAPER ROLL SLITTING AND REWINDING MACHINE MODEL ZWSJ-2500

Usage and Features:

ZWSJ series Jumbo roll slitting and rewinding Machine is Mainly used to slit large base paper roll into two or three or four sections as required width and diameter. Widely used in paper mills and printing industry.

ZWSJ series Jumbo roll slitting and rewinding Machine is Mainly used to slit large base paper roll into two or three or four sections as required width and diameter. Widely used in paper mills and printing industry.

Suitable for slit large base paper roll into 2/3/4 sections.

Parameters:

Parameter/Model | ZWSJ-2000 | ZWSJ-2500 | ZWSJ-2640 | ZWSJ-3600 |

Jumbo roll width | Max.2000mm | Max.2500mm | Max.2640mm | Max.3600mm |

Jumbo roll diameter | Max.1800mm | Max.1800mm | Max.1800mm | Max.1800mm |

Brake type | Pneumatic | Pneumatic | Pneumatic | Pneumatic |

Tension Control | Automatic | Automatic | Automatic | Automatic |

Slitting Width | 3~4 section | 3~4 section | 3~4 section | 3~4 section |

Rewinding diameter | Max.1500mm | Max.1500mm | Max.1500mm | Max.1500mm |

Cutting Blade | 4 sets | 4 sets | 4 sets | 4 sets |

Working speed | 400~600m/min | 400~600m/min | 400~600m/min | 400~600m/min |

More photos:

Detailed Images

Introduction of product advantages or application effect or application mode

Unwind Stand

The unwind stand choose hydraulic shaft less type, it could load diameter 1800mm.

Equipped with pneumatic brake system on the unwind stand,ensure automatic tension control during working.

Easy for operation

Unload Part

Equipped With unloading tipping bracket to unload the finished roll from machine body, safe and reliable.

The unloading part is controlled by hydraulic.

Cuttiing Unit

Choose good brand pneumatic blade OD150mm

Choose multi-edged bottom ring OD200mm

With Semi-automatic blade positioning function

Transmission unit for backing roller

Choose two backing roller diameter 420mm,there have torque difference between two backing roller, and the speed is controlled by two motor separately.

One backing roller surface plated Molybdenum, another backing roller is steel roller

Sample photos:

Similar model:

How to choose model:

Product packaging

Certificate

Company Introduction

JINAN CHENGDONG MACHINERY MANUFACTURE CO.,LTD. was founded in 1993 and have more than 20 years for manufacturing experience of paper-processing equipment in China. There are a group of senior engineers and technicians and R&D department to ensure the producing capacity and high quality. The company successively develops a group of leading products in homeland based on the ideology of constant development and creation. The main products including Paper roll slitting and rewinding machine, Spiral paper tube/core winding machine, Fibre/Paper drum production line, Composite can production line, Paper tube/core cutting machine, High-speed rotary paper roll to sheet cutting machine, paper board laminating machine, paper corner protector machine, Paper tube polishing machine and other different paper processing machines.

Our Advantages

Customer Photos

CONTACT US

Похожие товары

Резак для бумаги, диаметр 44 мм

US $61.00-$64.00

Ручной пресс машина книга пресс плосковязальной машине (WD-900E)

US $300.00-$400.00

Бумажная папка Письмо Конверт брошюра Складная машина производитель

US $399.00-$499.00