Низкая Цена Опилки Древесные щепы сушилка Поворотное оборудование для

- Категория: Сушильное оборудование >>>

- Поставщик: Zhengzhou,Dingli,New,Energy,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 23562.69 $* | 24740.8 $* |

| Aug-17-2025 | 23364.61 $* | 24532.15 $* |

| Jul-17-2025 | 19602.98 $* | 20582.91 $* |

| Jun-17-2025 | 22968.98 $* | 24116.85 $* |

| May-17-2025 | 19998.41 $* | 20998.97 $* |

| Apr-17-2025 | 22572.12 $* | 23701.76 $* |

| Mar-17-2025 | 22374.27 $* | 23493.46 $* |

| Feb-17-2025 | 22176.91 $* | 23285.71 $* |

| Jan-17-2025 | 21978.27 $* | 23077.97 $* |

Характеристики

Product Introduction

Product Application

Product Configuration

Main Features

2.The design of heat conduction pipe is simple, space-saving and convenient for maintenance and repair.

3.Short drying period. High efficiency and energy saving.

4.Large output and high heat efficiency. For unbound water, the heat efficiency can be as high as 60%.

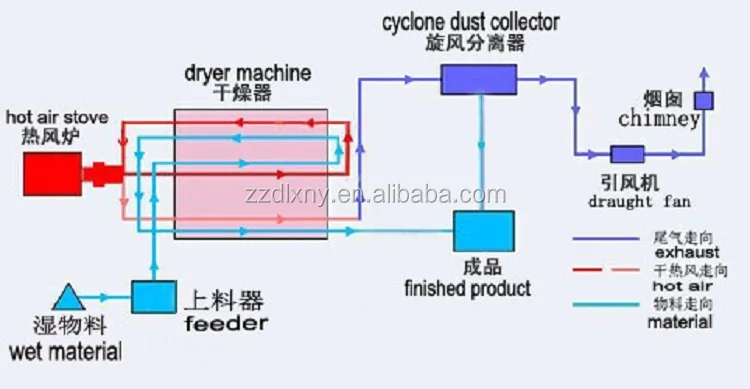

Below is Drying Process

Other Related Technical Parameters

We can help optimize the drying process according to the property of different materials, production scale, application requirements, cost control, automation level and site condition.

Model(DLSG) | 1409 | 1615 | 2008/3 | 2010/3 | 2210/3 | 2510/3 | 2512/3 | 2912/3 | ||||||||

Input Capacity(t/h) | 1.53 | 2.89 | 5.20 | 6.63 | 7.24 | 8.91 | 10.50 | 12.14 | ||||||||

Output Capacity(t/h) | 1.08 | 2.03 | 3.67 | 4.68 | 5.11 | 6.29 | 7.41 | 8.57 | ||||||||

Vaporization(t/h) | 0.45 | 0.85 | 1.53 | 1.95 | 2.13 | 2.62 | 3.09 | 3.57 | ||||||||

Early Moisture(%) | 40±5% | |||||||||||||||

Final Moisture(%) | 15%(adjustable) | |||||||||||||||

Drying Temperature(°C) | 280±30℃ | |||||||||||||||

Total Power(KW) | 34 | 45 | 78 | 90 | 105 | 125 | 140 | 155 | ||||||||

Total Weight(T) | 22 | 28 | 40 | 45 | 50 | 60 | 68 | 76 | ||||||||

Plant Area(M) | 5*15 | 6*22 | 8*16 | 8*18 | 8*20 | 10*20 | 10*24 | 10*24 | ||||||||

Except above models, we also can supply special model according to your requirements. | ||||||||||||||||

Below is Dingli Group Packaging & Shipping:

Your device will be packed well in container and suit for long ocean shipping.

Below is Dingli Group Service Items:

Pre-sale

1. According to your needs, select right model for you.

2. According to your special requirements, design customized solution and manufacture customized products for you.

3. Welcome your visit.

Sale

1. Sign contract, pay deposit, we arrange production.

2. Product acceptance.

3. Help you formulate construction scheme.

After-sale

1. Assign engineer service for you on-site freely.

2. Install and adjust device, train how to operate.

3. After installation, leaving 1-2 technical staff to help you on-site production, until achieve customer satisfaction.

Biomass Rotary Dryer

Sawdust Dryer

Chicken Manure Dryer

Beer Yeast Drum Dryer

Brewer Spent Grain Dryer

Biomass Wood Pellet Production Line

Coconut Fiber Dryer

Coal Slime Dryer

Belt Dewatering Machine

Dingli Group Advantage:

1. Over 200 employees, 98% professional technical personnel;

2. Factory size over 15,000 square meters;

3. 480 Inventions & Patents

4. Exported over 80 countries,300 global partners;

5. Rank 3rd in China Drying Industry;

6. Customize Drying Production Line.

Below are Dingli Dryer Factory & Sales Team & Production Workshop Pictures:

Below are Dingli Group Honors & Certificates & Patents:

Below are Dingli Customers Visiting:

Dingli Dryer Production Line has exported to over 80 countries with 300 foreign partners, such as Germany, Britain, United States, Italy, Israel, Chile, Thailand, Russia, Vietnam, India, Cambodia, Indonesia, Malaysia, Thailand etc.

Below are Installation Sites of Our Customers:

After reach deals, Dingli Engineer will fly to your address, install and adjust machine for you freely.

Also train you operation skills, until you are satisfied.