Hpl фанерная пленка ламинат МДФ машина для горячего прессования клея деревянный шпон ПВХ ламинирования

- Категория: >>>

- Поставщик: Foshan,Leader,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 64855.80 $* | 68098.58 $* |

| Aug-17-2025 | 64310.17 $* | 67526.80 $* |

| Jul-17-2025 | 53955.43 $* | 56653.69 $* |

| Jun-17-2025 | 63220.1 $* | 66381.64 $* |

| May-17-2025 | 55045.80 $* | 57797.97 $* |

| Apr-17-2025 | 62130.27 $* | 65237.13 $* |

| Mar-17-2025 | 61585.86 $* | 64664.78 $* |

| Feb-17-2025 | 61040.58 $* | 64092.20 $* |

| Jan-17-2025 | 60495.28 $* | 63520.36 $* |

Характеристики

PRODUCT INFORMATION

TECHNICAL CHARACTERISTICS

Overall Size | Approx. 16500*2200*2000 mm |

Weight | Approx. 15000 kg |

Power Supply | 380V 50Hz or customized |

Total Power | 65 kW |

Pneumatic Load | 6 bar |

Working Speed | Up to 18 m/min |

Profile Application Spec. | Width: Up to 1300 mm Thick: Up to 50mm |

Foil Application Spec. | Core Dia.: 3in. Foil O.D.: Up to 400mm Foil Width: Up to 1300mm |

Control System | Schneider® PLC with 10in. full color touch screen. |

Glue Melter (200-Liter Drum Melters) | Barrel Type Pail: 200 liter or 55 gallon Pail Diameter: 571 or 567mm Melt Capacity: 240kg/hr Num. of Hoses: Dual Temp. Control Sensor: PT100 Glue Type: PUR, EVA, Polyolefine etc. |

Electronic Components | Schneider® or equivalent |

Pneumatic Components | AirTac® or equivalent |

DETAILS DISPLAY

MACHINE FEATURES

DOUBLE SIDES VACUUM BRUSHES CLEANSING SYSTEM

● Effectively clean the boards from all direction to avoid the potential defect due to the dust or chips.

*compressed air cleaning is optional.

*compressed air cleaning is optional.

HEATING TUNNEL SYSTEM

● Effective Infrared heating unit.

● Independent temp. control unit.

GLUE APPLICATOR

● Applied by a roller made of ceramics which is smooth enough to ensure the uniform distribution of the application.

● With precise glue melting system, fast heating up and easy reloading glue barrel.

● Fully monitoring and error indication system to ensure the safety and smoothness of the production.

● With precise glue melting system, fast heating up and easy reloading glue barrel.

● Fully monitoring and error indication system to ensure the safety and smoothness of the production.

LAMINATION SECTION

● Fast changing design for foil loading, auxiliary device for foil loading / unloading.

● Independent magnetic powder tension control system for foil unwind shaft to make foil feeding consistent.

● Diameter of 350 mm roller group including steel roller and silicone roller to ensure the pressing force applied to the materials evenly.

● Hydraulic adjustable pressing system provides stable and powerful force to the boards.

● Multiple lamination function, foil in roll or veneers in sheet.

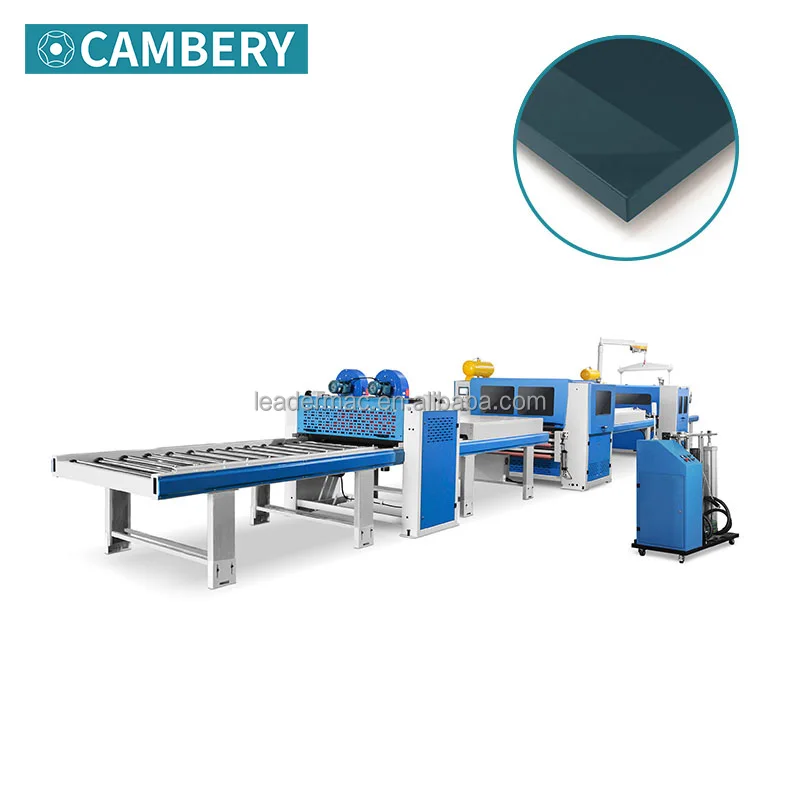

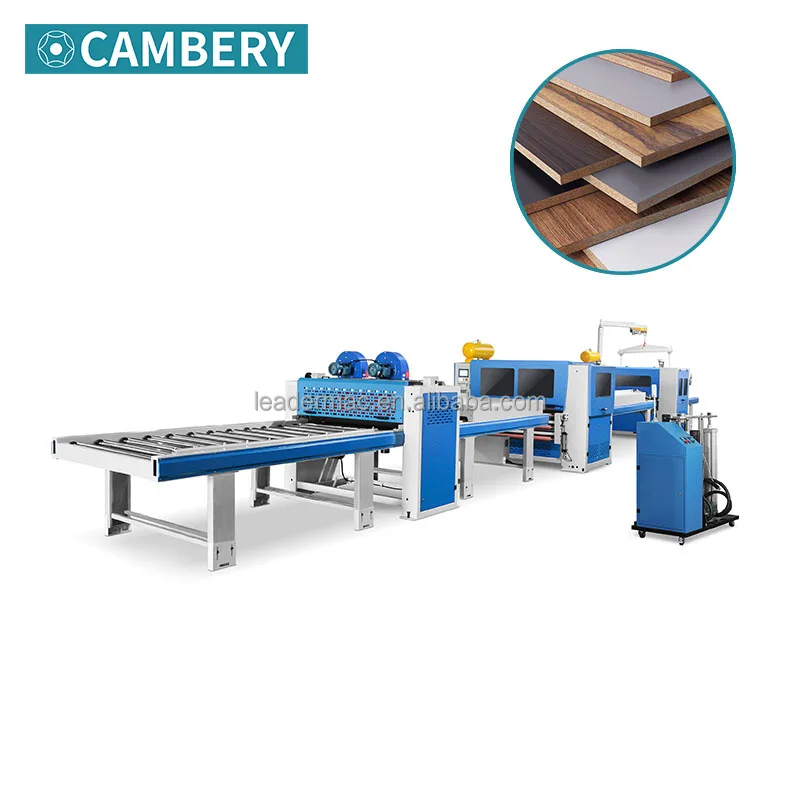

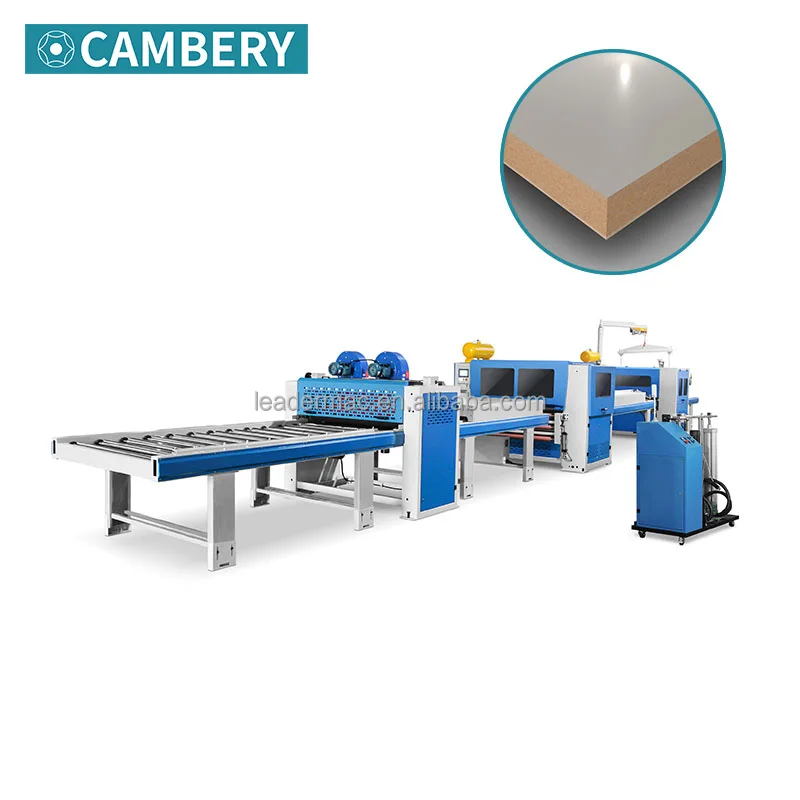

APPLICATION

Multi-functional for the roll form of PVC and sheet forms like HPL, CPL, aluminum foils and veneer.

HOT SALE

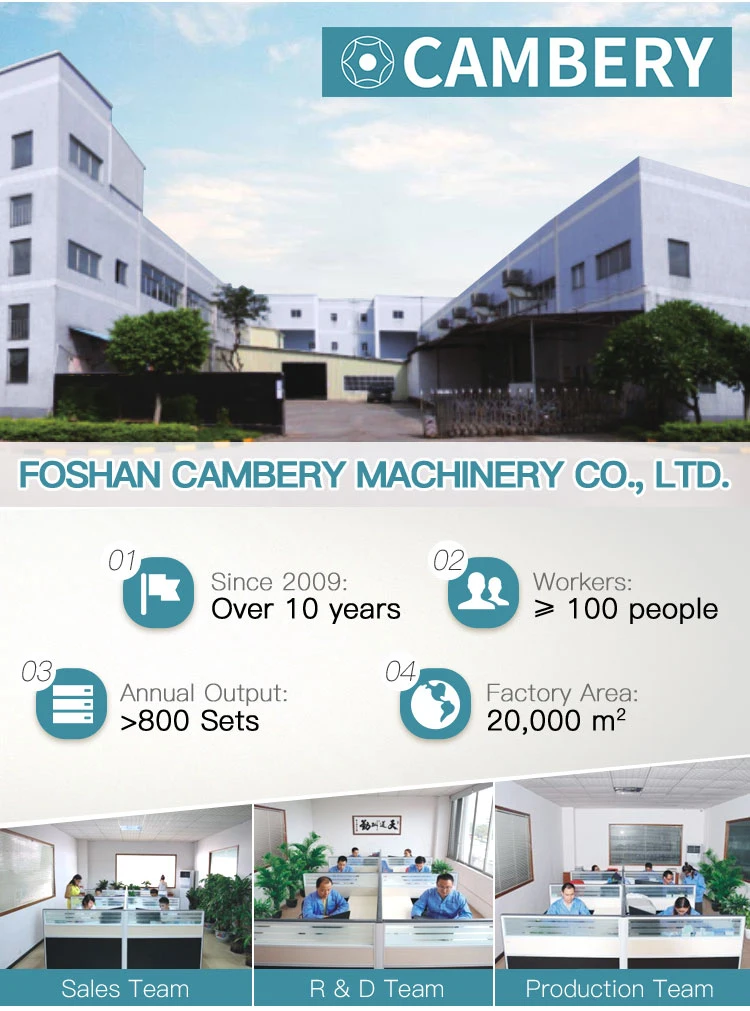

COMPANY OVERVIEW

WELCOME TO VISIT US

Cooperation with up to 50 countries around the world.

Cooperation with up to 50 countries around the world.

OUR CERTIFICATION

FAQ

Q1. Warranty

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

A1. 12 months warranty is effective from the date of acceptance of the machine.

Q2. Payment Terms

A2. TT 30% down payment, 70% before shipment.

Q3. Delivery Time

A3. 15-30 working days from the receipt of the down payment.

Q4. Machine installation

A4. Cambery could assign the technician to the place for the on-site installation if requested by the purchaser.

Q5. Technical Support

A5. Every machine is assigned by a specialist. The response is available within 12 hours while the solution for the

troubleshooting is provided within 48 hours.

Q6. Demo and Testing

A6. Cambery built a training center for the clients and employees to study the machines operation. You are welcome to visit our factory anytime for the machines’ demo. Furthermore, we could run the machine with the materials provided by you and help you achieve your business efficiently.

Похожие товары

Машина для ламинирования мягкой пленки с жидким клеем

US $11000-$12000

Высокоскоростная машина для ламинирования рулонов без растворителей

US $80000-$120000

Деревообрабатывающая машина для ламинирования ПВХ пленки МДФ

US $8300-$52000