Полиэтилен высокой плотности волоконно-оптический microducts микро-канальные воздуховодов пакет Связки труба

- Категория: Plastic Extruders >>>

- Поставщик: Cissco,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 59381.96 $* | 62350.63 $* |

| Aug-15-2025 | 58882.48 $* | 61826.39 $* |

| Jul-15-2025 | 49401.18 $* | 51871.80 $* |

| Jun-15-2025 | 57884.3 $* | 60778.42 $* |

| May-15-2025 | 50399.69 $* | 52919.52 $* |

| Apr-15-2025 | 56886.83 $* | 59730.65 $* |

| Mar-15-2025 | 56387.49 $* | 59206.28 $* |

| Feb-15-2025 | 55888.1 $* | 58682.49 $* |

| Jan-15-2025 | 55389.91 $* | 58158.66 $* |

Характеристики

HDPE microduct bundle pipe making machine

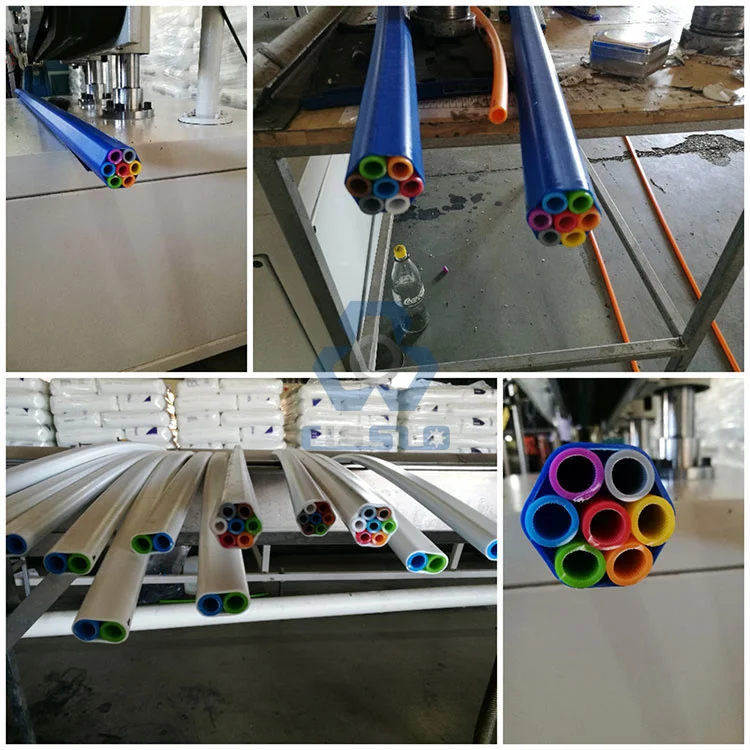

I. Final products from our machine

II. Common information of machine line

1. In view of operation safety, machine equipped with:

- E-stop switch;

- Control system to prevent machine from damaged at abnormal condition;

- Flash lamp and voice show machine is under abnormal running condition;

- The parts which probably cause damage to operation staff are all designed with protection.

2.The following technical documents included in the content of purchasing object:

- Installation layout diagram of machines;

- Circuit diagram of machines;

- Operation manual of machines;

- Certificte of machine quality;

- Certificate of machine warranty by supplier;

- Spare parts (refer to spare parts list).

3.Name and model : SJ75-GF63 HDPE micro-duct bundling pipe extrusion line

- Output: Max 160 ± 10%Kg/h;

- Environment: Indoor, humidity 0.85, no condensation point, temperature≤40℃;

- Power supply: 380V 50HZ, 3-phase 4wires; Install power ≤110KW;

- Circulation water flow: 6-8.0m3/h;

- Compressed air: 0.6-0.7Mpa.

- Operation direction of production line is from right to left direction;

- Core height of production line is 1100mm;

- Install space: 35.0m x 3.5m x 3.5m (length x width x height);

- Color of machine: RAL 7035; Or according to client appointed color.

III. Specifications of TUBE

- Raw material: HDPE granule;

- Size of pipe: OD 10-63mm

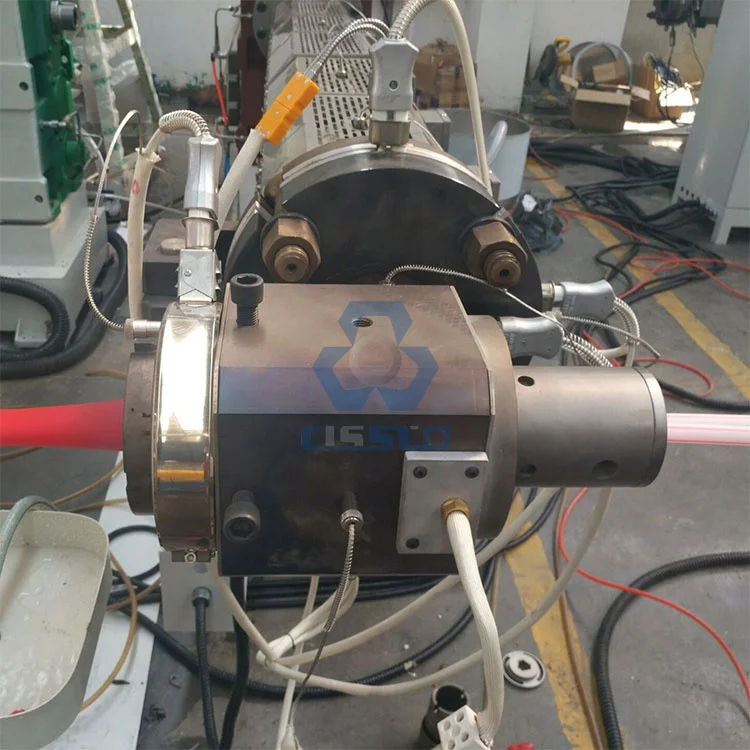

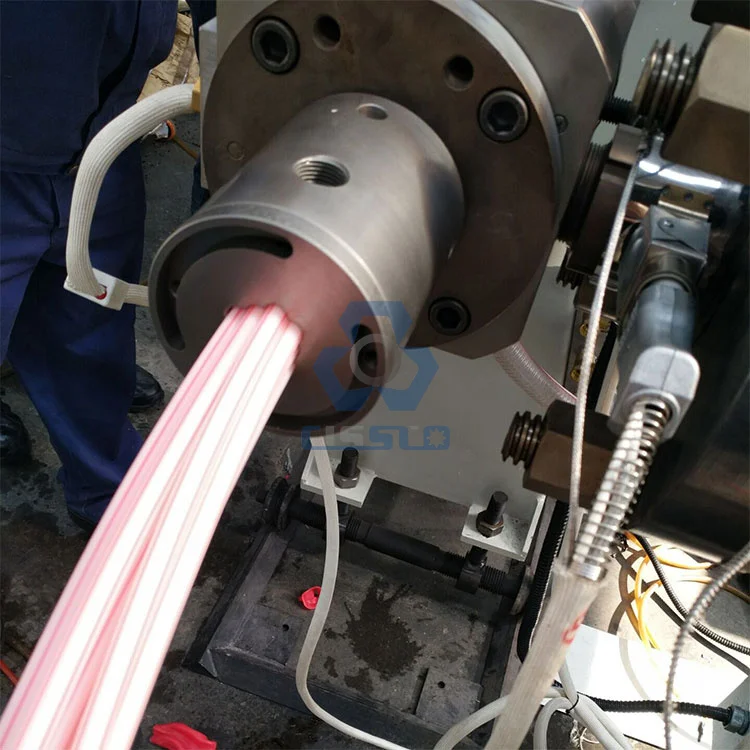

IV. Configuration of Bundle tube extrusion line

| Item. | Equipment Name | Model | QTY/set |

| 1 | Unreeling frame (coiling frame) | FJ-1400-4GW | 1 |

| 2.1 | Automatic loader | JLD30 | 3 |

| 2.2.1 | Hopper dryer | GZ-200E | 1 |

| 3.1 | HDPE Single screw extruder | BDSJ-75/33 | 1 |

| 3.2 | HDPE Single screw extruder | BDSJ-65/30 | 1 |

| 3.3 | Silicon Single screw extruder | BDSJ-45/25 | 1 |

| 3.4 | Volumetric type co-extrusion mold | GM-75BF-G | 1 |

| 4.1 | Vacuum spraying cooling tank | ZDX-6000P | 1 |

| 4.2 | Spraying cooling tank | PLX-6000 | 1 |

| 4.3 | Chiller (Air cooling) | LS-210F | 1 |

| 5 | Multi cylinder clamping belt puller | QYP-1250-5 | 1 |

| 6 | Gantry type single peck reeling machine | SJQ-2000L | 1 |

V. Machine photos:

- what about the size of bundle pipe?

- what's the size of microduct?

- do you need mark line one the out surface of bundle pipe?

- do you also need microduct machine?

1. We design, engineer and manufacture and customized the extrusion line.

2. Choosing the right solution: In plastics manufacturing, process is everything. We carefully evaluate each project's requirements, weigh the options and recommend the best solution for the client.

3. Training & Development: we offer extensive start-up assistance, comprehensive training. As well as Engineers for training and installation at our client’s factory

4. Support: We support the client in all the stages of the project life cycle, as well as the constant spare parts supply in a time efficient manner.

CissCo Machinery Co., has been engineering and manufacturing a series of EXTRUSION MACHINERY for more than 20 years and has thus acquired an extensive expertise in the supply of manufacturing machinery; having based ourselves on the features demanded by large companies in more than 30 countries.

Comparing with the low price low quality machine, please note our strong advantages:

1. 20 Years Experiences;

2. European Latest Technology;

3. Easy to Operate, Stable Performance, Good Quality Products, Low Production Cost;

4. Quicker Production Speed, Big Output;

5. Good Material and Well-Known Brand Electrical Parts;

6. Beautiful Appearance;

7. Free Training for Technical Process, Formula and Know-How;

8. Full Time and High Level After-Sale Services.

l Contactor: Mr. Louies Liu

l Skype: louies.cissco

l Cellphone/Whatsapp/WeChat: +86 18917527205

l Web: www.cisscomachinery.com

l Add: No. 58, New Jinqiao Road, Pudong, Shanghai, China