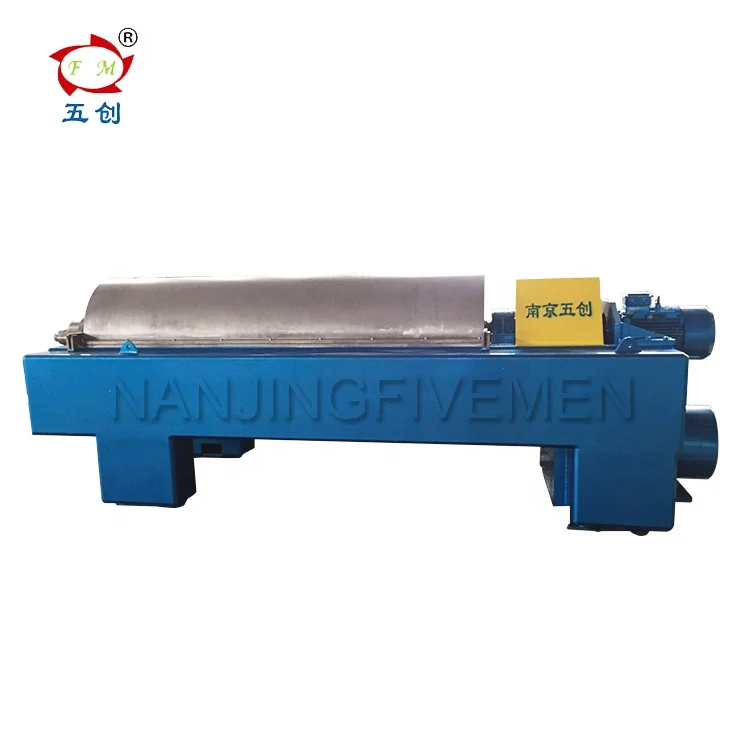

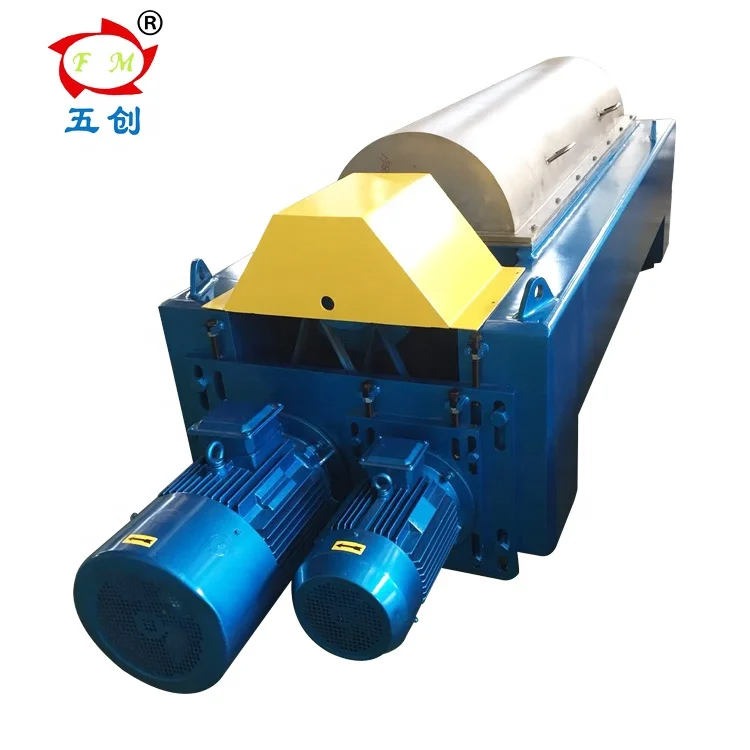

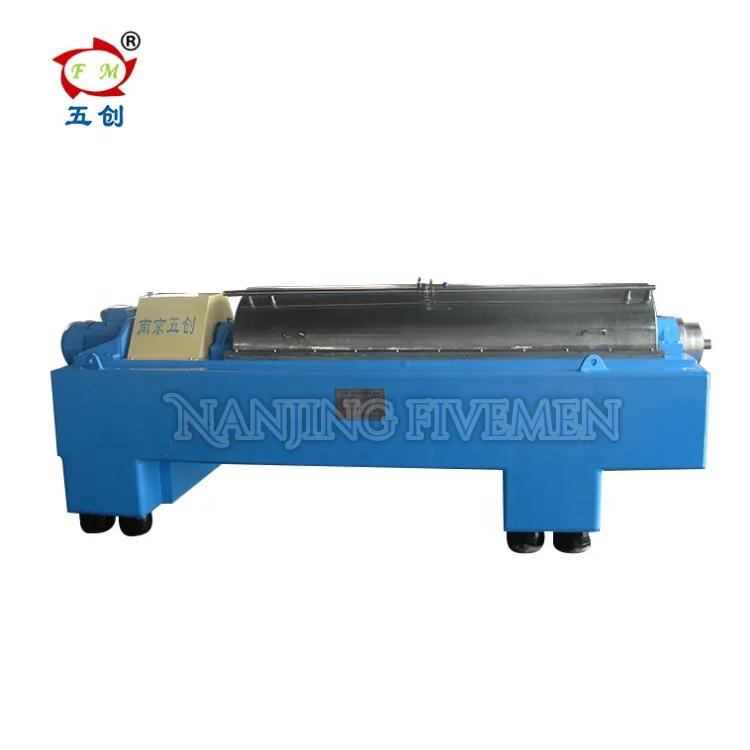

Горизонтальная непрерывная центрифуга для декантера рыбного

- Категория: Separation Equipment >>>

- Поставщик: Nanjing,FiveMen,Machine,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 0.23 $* | 0.90 $* |

| Aug-19-2025 | 0.39 $* | 0.71 $* |

| Jul-19-2025 | 0.88 $* | 0.86 $* |

| Jun-19-2025 | 0.38 $* | 0.7 $* |

| May-19-2025 | 0.83 $* | 0.92 $* |

| Apr-19-2025 | 0.54 $* | 0.29 $* |

| Mar-19-2025 | 0.76 $* | 0.30 $* |

| Feb-19-2025 | 0.61 $* | 0.55 $* |

| Jan-19-2025 | 0.47 $* | 0.28 $* |

Характеристики

Horizontal continuous fish oil decanter centrifuge

Horizontal screw centrifuge is for 0.002-3mm material for clarification, separation, dehydration, or

classify 1um-5um solid phased particles.

It is wide application range, work continuously, large processing capacity, low cost, convenient

maintenance and so on. It is the best equipment for separating solid-liquid.

The technological procedure of Three-phase Solid-bowl Centrifuge:

The fish water after fish rolling flows into the temporary storage tank, charged by pump or high level tank, before which the fish water shall be heated to 85-90 degrees by steam heater or electric heater, and then enters to the three-phase solid-bowel scroll centrifuge to be separated; The fish scraps, fish oil and waste water are separated for one time. Fish oil is canned through steam or other heating approaches, and the waste water is sent to the dryer for evaporation through pumps, while the fish scraps are also sent to the dryer, processing into fishmeal by the conveyer.

Reference standard

1. Main standard of the national machinery industry.

JB/T502-2004 "spiral discharge sedimentation centrifuge"

JB/T9095-1995 "centrifuge, separator forgings, welding conventional NDT technology standard"

2. The national main standard

GB10894-89 "separation machinery noise sound power level measurement engineering method"

Application

It is widely used in chemical industry, light industry, medicine, food, paper making, mining and other industries.

For LW decanter centrifuge, we have two different types, one is LW decanter centrifuge , which is two phase centrifuge(solid liquid centrifuge), another is three phase centrifuge (solid liquid liquid centrifuge.)

1) City tap water, domestic sludge dewatering;

2) Oil drilling mud dewatering;

3) Sludge Oil Recovery;

4) Fruit juice separation

4) Refinery sludge concentrated dehydration;

5) Distiller ‘s grains dehydration;

6) Paper, printing and dyeing wastewater separation;

7) Medical sludge dewatering;

8) Soy protein dehydration;

9) Plant oil clarification and separation;

10) Cosmetic clarification and separation;

11) Bleaching powder separation.

12)coal tar separation

LW two phase

Type No. | Length to diameter ratio | Motor power(KW) |

LW260 | 3.5-4 | 7.5-11 |

LW355 | 11-37 | |

LW420 | 2-4.5 | 15-45 |

LW450 | 2-4.5 | 18.5-45 |

LW480 | 2-4.5 | 18.5-55 |

LW530 | 2-4 | 22-75 |

LW650 | 2-4 | 37-110 |

LW750 | 2-4 | 55-132 |

Type | Bowl diameter(mm) | Bowl length/ Bowl diameter | Main Power(Kw) |

LWS355 | 355 | 3.3-4.5 | 15-18.5 |

LWS420 | 420 | 4.1 | 22 |

LWS500 | 500 | 4.2 | 30 |

LWS530 | 500 | 4.2 | 30 |

LWS580 | 580 | 4.1 | 45 |

LWS620 | 620 | 4 | 45 |

Note: In case of differences between the table and the user manual, the latter shall prevail. | |||

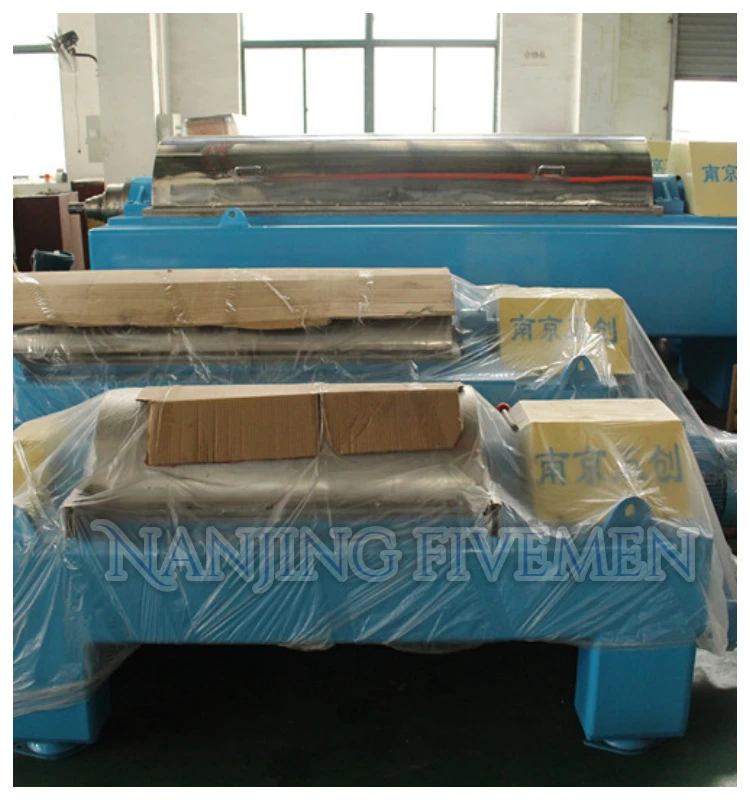

Machine freight by truck or container. Container machine be fixed by steel wire, to make sure all of them not be damage by transport jolt.

Application site:

1. 12 months guarantee period from machine arrive date.

2. Abundant spare parts in stock are available to provide.

3. Our technicians could be dispatched for overseas service.

4.7* 24 hours technical consultation.

5.Your workers could get trained both in our factory and yours.

6.Routine tracing till the machine work properly will be done timely.

7.We will remind you to do the normal maintenance.

8.Your suggestions or any comments & reflection would be treated in priority.

9.Marketing team will visit you during our visit to your country if your require.

About FAQ

In order to quota you best price, please let us know the following information:

1. What’s your raw material?

2. Material related characteristic? Does it viscous or corrosive, strong basicity or highly acid?

3. What’s the capacity per hour?

4. Water content? solid content percentage?

5. What kind of heat source? steam? electric? or fuel gas or thermal oil?

6.What kind of voltage of your country?

Any questions, pls feel free to contact us.

Whatsapp/ Wechat: 008613151637387

Quality policies: Excellent Quality, Leading Technology, Sincere Operation and Customer Satisfaction.

Core tenet: Sincere Operation, Mutual Benefit

Nanjing Fivemen machine CO., LTD is a professionally engaged in design, manufacturer, testing,and installation of centrifuges and separators.

Over the years, our products have beensuccessfully applied in the mineral oils, dairies, fruit and vegetable juices,pigments, animal and plant oils, starches, bio-pharmacy, fermentation broth,additives, foods, oil extraction, fish oil feeds, grading of non-metallicminerals, petroleum chemistry, sewage treatment and other industries. Ourcustomers spread through the whole nation except Tibet, and our products aresuccessfully exported to Japan, North Korea, South Korea, Taiwan, Thailand,Malaysia, Vietnam, Burma, India, U.S.A., Africa and some Latin Americancountries.

We have passed ISO9000 quality system certificationawarded by China Classification Society; our mineral oil separators used ininland rivers, offshore and ocean shipping have achieved CCS approvalcertificate, and the products used in fishing boats also passed the fisheryinspection. In the past years, we have been awarded a number of honors such as "High-qualityProducts in Jiangsu Province", "Grade AAA Demonstration Unitin Quality, Service and Credit of Jiangsu Province", "StarEnterprise in Jiangsu Province", "Grade AAA Brand Enterprisein Quality and Integrity of Jiangsu Province" and so on.

Q1: Where can I get product & price information?

A1: Send us inquiry or email directly, then we will contact you ASAP.

Q2: How can I make sure your machinery is suitable for me?

A2: Please tell all the separation information you know, such as your raw liquid,

two-phase or three-phase separation, solid content in liquid, solid size, the purpose, etc. After analyzing your information, we will to choose a suitable model for you, and send the details and videos to you.

Q3: What should I do if I want to see the separation effect?

A3: If you can come to our factory with the raw liquid, we will provide test service. Or you deliver the raw liquid to us, and we will do a test, and supply you the testing videos.

Contact Information:

Contact name: Sunny Cheng

Phone: +86-13151637387

WhatsApp: +86-13151637387

Wechat:+86-13151637387