4874 Ротационная Машина Для Резки Рулонов Бумаги штамповочная машина для резки

- Категория: Станки для обработки бумаги >>>

- Поставщик: Ruian,Dapeng,Printing,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 147560.51 $* | 154938.30 $* |

| Aug-17-2025 | 146320.98 $* | 153636.65 $* |

| Jul-17-2025 | 122760.0 $* | 128898.97 $* |

| Jun-17-2025 | 143840.23 $* | 151032.65 $* |

| May-17-2025 | 125240.21 $* | 131502.27 $* |

| Apr-17-2025 | 141360.97 $* | 148428.92 $* |

| Mar-17-2025 | 140120.32 $* | 147126.46 $* |

| Feb-17-2025 | 138880.16 $* | 145824.7 $* |

| Jan-17-2025 | 137640.41 $* | 144522.96 $* |

Характеристики

Product Application

The integrated DP-A4874 Rotary Die Cutting Machine is a suitable equipment for different production. It is suitable for small batch and repeated production. It use flexible mould and easy to replace. The max sheet size is 480X740mm.It is suitable for die cutting, creasing, stripping, which can realize full cutting and half cutting of printed products. Mainly suitable for stickers, tags, wine labels, playing cards, small boxes and so on. The processing materials are suitable for plain paper, coated paper, cardboard, PE film, and so on.

DP-A4055 | DP-A4874 | |||

Cut size (before processing) (width x length) | Biggest size | 400*550mm | 480*740mm | |

Smallest size | 240*280mm | 240*280mm | ||

Cut thickness | Die cutting thickness | 0.13-0.5mm | 0.2-0.5mm | |

Max indentation thickness | 0.4mm | 0.4mm | ||

Finished product size (with separator: width x length) | Biggest size | 376*530mm | 456*720mm | |

Smallest size | 50*80mm | 50*80mm | ||

Minimum waste width | 5mm | 6mm | ||

Knife size (width x length) | Knife thickness | 0.8mm | 1mm | |

Biggest size | 400*560mm | 480*750mm | ||

Smallest size | 160*100mm | 160*110mm | ||

X.Y direction die cutting accuracy | ±0.1mm | |||

Paper stacker height | 500mm | |||

Maximum operating speed of the machine (rev / hour) | 6000 | |||

Rated voltage | Simplex 200~240V, 50/60HZ | |||

Rated power | 2.5KW | 4.5KW | ||

Equipment weight | 1100KG | 2440KG | ||

Dimensions (length X width X height) | 3680*980*1250mm | 4650*1310*1620mm | ||

Main Features

1.Operation Console:

Both setup and control can be done though the intuitive touch screen. After setting upper and lower die, the system can be set up by simply inputting sheet size and product size. The graphical illustrations on the screen are simple and easy to understand.

2.Feed Section:

Vacuum belt feeding enables superior feeding with easy setup and operation. An ultrasonic sensor is used for double feed detection on a wide range of substrates.

3.Transport Section:

Sheets are registered by vacuum belt and position is firmly secured with gripper rollers for high quality finish. Servo motor driven gripper rollers ensure the die cut position without effecting processing speed.

4.Die Cutting:

Rigid magnetic upper roller and solid lower anvil roller ensure high quality die cutting. Uniquely designed die cutting section enables easy and quick die setting.

5.Separator:

The separator removes the waste from the finished product and delivers it to the waste bin. Air cylinder driven separator pins and sir jets can be used depending on size of the waste.

6.Delivery Section:

Finished products are delivered on the motorized conveyor. Intermittent conveyor movement maximizes the continuous operation in a small space. Gap can be adjusted depending on the size of the product for easy handling.

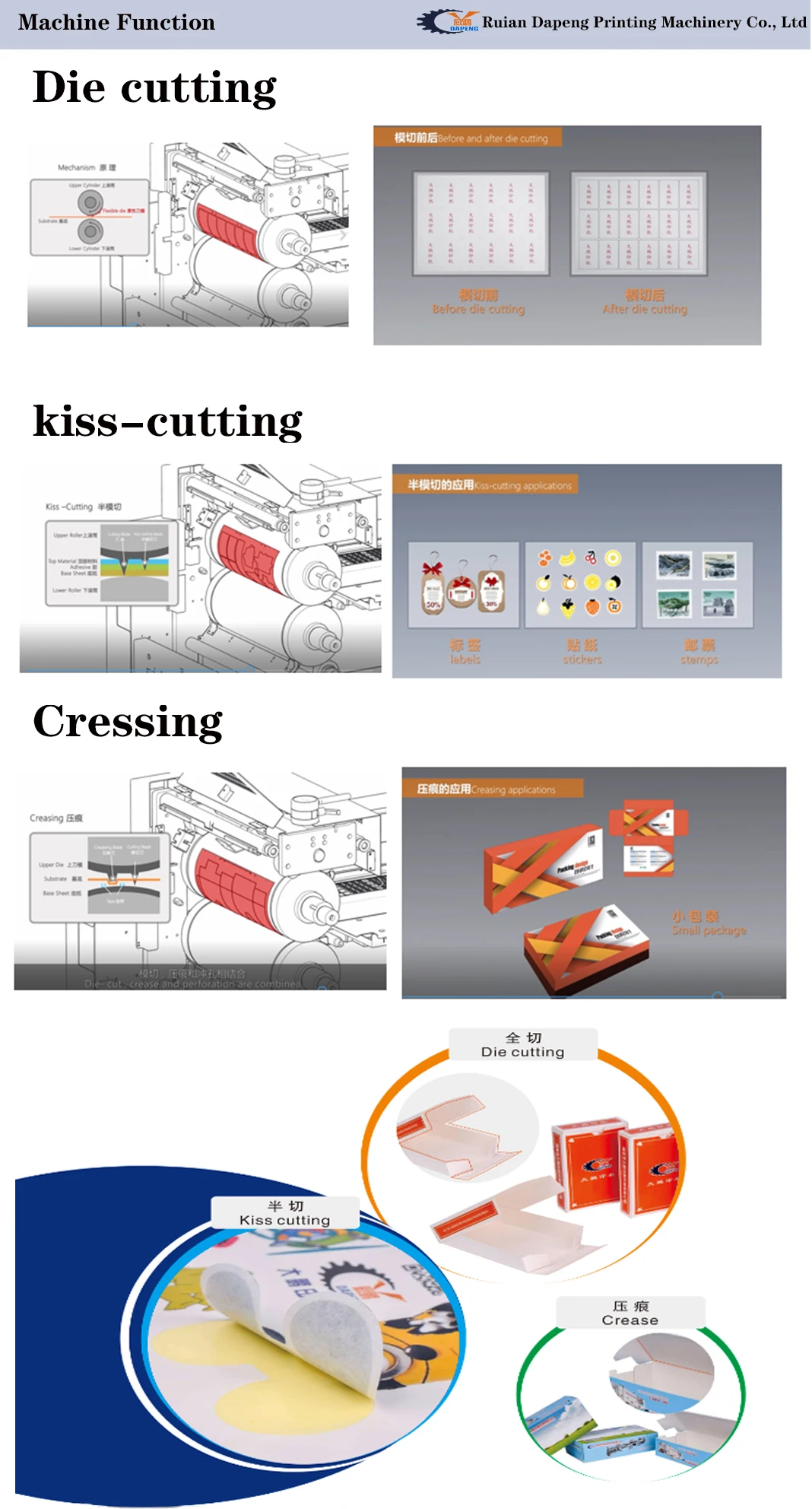

7.Multi-functional system die cutting,kiss cutting creasing,repeat cutting

8.Flexible substrate-Die cut, Crease, Perforation, Silt, Hole punch and round corner in various substrates up to 0.5mm(only for die cutting)thickness for digital and offset printed sheets.

9.One pass processing-Feeding, die cutting and separating are achieved in one pass at a speed of 6,000 cycles per hour.

10.Simple and easy operation-Reduces costly labor steps and increases productivity.

rotary die cutting machine/ die cutting machine/ sheet to sheet/ flexible cut/ no embossing/ play card/ boxes/ creasing/ kiss cut/ repeat die cut/ perfect cut