Оцинкованная сталь PPGI трапециевидная машина для формовки листового металла

- Категория: Другие машины производства строительных материалов >>>

- Поставщик: Hangzhou,Zhongyuan,Machinery,Factory

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.67 $* | 0.57 $* |

| Aug-18-2025 | 0.45 $* | 0.37 $* |

| Jul-18-2025 | 0.97 $* | 0.27 $* |

| Jun-18-2025 | 0.67 $* | 0.44 $* |

| May-18-2025 | 0.17 $* | 0.4 $* |

| Apr-18-2025 | 0.43 $* | 0.3 $* |

| Mar-18-2025 | 0.29 $* | 0.52 $* |

| Feb-18-2025 | 0.92 $* | 0.27 $* |

| Jan-18-2025 | 0.11 $* | 0.65 $* |

Характеристики

Galvanized Steel PPGI Trapezoidal IBR Metal Roofing Sheet Roll Forming Machines

Why choose this machine?

Certificate: ISO, CE,

Lifetime services

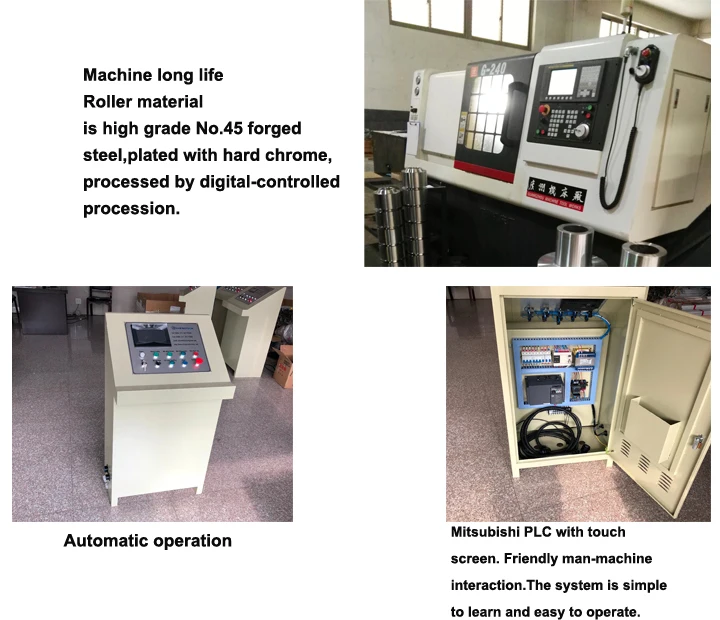

Control system: Mitsubishi PLC with touch screen.

Product cut-to-length.

Engineer overseas installing and training available

15 years skillful engneers to design and make your machines

1.Technical Parameter Of Metal Sheet Roll Forming Machines:

Item | Specification | |

Material | Type | Pre-painted steel coil & galvanized coils |

Thickness | 0.4-0.7mm | |

Yield strength | 235Mpa | |

Roller material | 45#Chrome steel | |

Forming speed | 35-40m/min | |

Speed adjusting mode | AC Frequency | |

Roller drive | Decelerating motor + Chain drive | |

Cutting mode | Hydraulic cutting | |

Cutter material | Cr12 mould steel | |

Length measurement | Encoder | |

Control mode | Mitsubishi PLC | |

Operating mode | Button + Mitsubishi Touch screen | |

Main motor power | 7.5KW | |

Hydraulic station motor power | 2.2 KW | |

2. Components of Metal Sheet Roll Forming Machines:

Decoiler | 1set |

Feeding & guiding device | 1set |

Main roll forming machine | 1set |

Hydraulic cutting system | 1set |

Controlling system | 1set |

Run out table | 1set |

Roofing forming machine with improved structure:

1) Thickness of wall panel for machine is 40mm, the structure is more stronger than old style wall, so that machine life is much longer.

2) This structure is based on European machines’ structure, the outlook of machine is also more attractive now.

3) The producing speed of our improved structure machine can reach about 25m/min, much more efficient.

4) We can insure life time of improved structure machines more than 15 years with correct operation and maintain.

Established in 003, Zhongyuan Machinery Factory is experienced manufacturer of metal forming machinery with ISO quality system.

Our R&D department is staffed with senior engineers who has more than 20 years experience in metal forming machine industry, So we are able to assist customers with professional designing and solution.

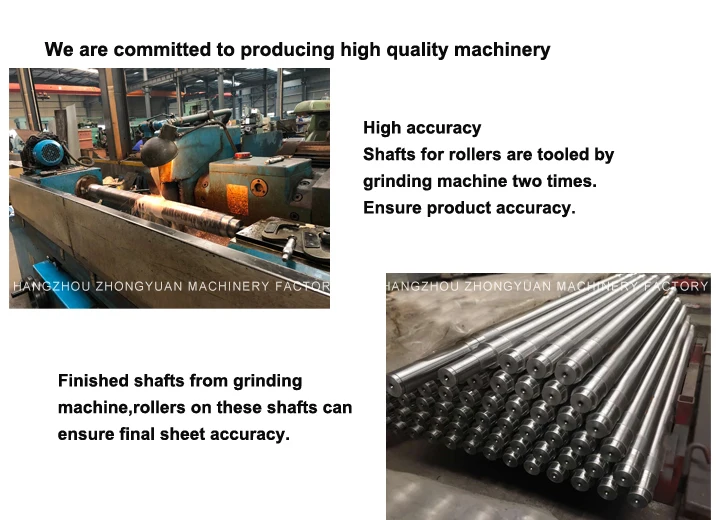

We are“All-in-house source” – from raw material to the final high-precision forming machine. Our own tooling center is equipped with CNC turning-lathes, Grinding machine for roller shaft, Heavy planing machine,etc,which allow us to complete the majority of our processing procedures on-site. So we can better control the machine quality and delivery time of machines.

Our range of products: sandwich panel production line, roof tile forming machine, cladding forming machine, metal decking forming machines,etc. We also can supply steel coils,EPS sandwich panels,PU sandwich panels to suit diverse requirements of our global customers.

Today, we have exported our machines to America, Chile, Mexico, Bolivia, Brazil, Colombia, Argentina, Ecuador, Honduras, Australia, Fiji, Papua New Guinea, Kuwait, Syria, Oman, Saudi Arabia, U.A.E, Nigeria, Tanzania,Ethiopia, Gana, Guinea,South Sudan, Algeria, Niger, Philippines,Indonesia,India, Russia, Azerbaijan and Kazakhstan.

We have rich experience for metal forming machine solution,competitive price and excellent service. We will continue to do our best to supply perfect products and service for customers. Invite you to contact us for further information.

We are professional in making roll forming machines since 2003.

Company occupies 6650, in which 5650 for workshops.

1. Capacity: 12-15 sets/month

2. Delivery: in only 5-8 weeks for urgent order

3. Have our own tool center. 12 sets CNC machines to process machine rollers.

4. Zhongyuan is a "All-in-house source"

--from raw material to the final high-precision forming machine. We have our precise tooling center.

5. Over 15 years engineers to design and make your machines.

PACKAGE:

1. need about 1*40gp container for loading one set machine completely;

2. the whole Wiped Anti Rust Oil, PLC controller covered by foam film;

3. Spare parts and some small parts packed in plastic tooling box;

4. All Components Fixed by steel wire with Container.

DELIVERY TIME:

within 120 days after getting advance payment.