Энергосберегающая небольшая НЕОБРАБОТАННАЯ нефть для дизельного нефтеперерабатывающего

- Категория: Очиститель машинного масла >>>

- Поставщик: Chongqing,Vbolt,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.4 $* | 0.82 $* |

| Aug-16-2025 | 0.22 $* | 0.55 $* |

| Jul-16-2025 | 0.84 $* | 0.8 $* |

| Jun-16-2025 | 0.54 $* | 0.61 $* |

| May-16-2025 | 0.95 $* | 0.64 $* |

| Apr-16-2025 | 0.43 $* | 0.48 $* |

| Mar-16-2025 | 0.65 $* | 0.89 $* |

| Feb-16-2025 | 0.78 $* | 0.68 $* |

| Jan-16-2025 | 0.14 $* | 0.44 $* |

Характеристики

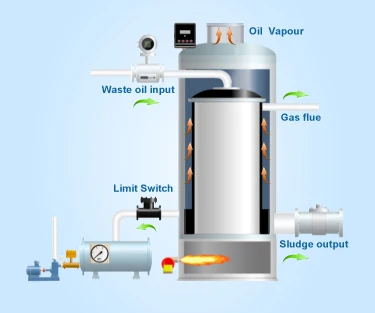

Power Saving Mini Crude Used Oil To Diesel Oil Refinery Plant

Best Quality 95% Recovery Rate Waste Vehicles Oil Recycling Refine To Diesel oil Plant. Vbolt oil distillation machine is suitable for all kinds of used oil (such as used engine oil, waste motor oil,waste industrialoil , heavy fuel oil , oil sludge etc.), pyrolysis oil (such as tire pyrolysis oil, plastic pyrolysis oil etc. ) recycling to light and heavy diesel oil or base oil.

(VBOLT supply 1 ton/day to 50 tons/day oil distillation machine, also supply demo machine with mini capacity.)

VBOLT Patent Thin Film Evaporator

Vbolt Membrane Distillation System

1.utilize high speed centrifugation to separate water content from waste oil.

1.utilize high speed centrifugation to separate water content from waste oil.

2.thin film evaporator to get rid of light components.

3.ealize oil gases dissociation via advanced membrane distillation system combining with continuously assistant heating source.

4.By catalytic cracking under different temperature collects diesel oil fragments.

First step,pump the waste oil,catalyst into the blending tank and keep stirring.In this process,a small fraction of water,impurities and mental particle will be removed.

Second step,the waste oil go through the tube furnance and flow into flash distillation tower.we need to increase the oil temperature to separate the water ,light oil and heavy oil.In this system,the oil can circulate till reach the temperature we needed.

Third step,the oil in the membrane distillation tower will forms a thin film and turns into gas at high temperature.the gas keeps rising and go to the rectifying column which can catalyze the gas into diesel oil molecules.after cooling through the condenser,the gas will become diesel oil .

Fourth step,the silica in the refinery system can remove some impurities and change the color of the diesel oil..

Third step,the oil in the membrane distillation tower will forms a thin film and turns into gas at high temperature.the gas keeps rising and go to the rectifying column which can catalyze the gas into diesel oil molecules.after cooling through the condenser,the gas will become diesel oil .

Fourth step,the silica in the refinery system can remove some impurities and change the color of the diesel oil..

used engine oil | waste tire oil | pyrolysis oil | used lubricant oil | industrial waste oil |

black oil | crude oil | plastic oil | heavy oil | hydraulic oil |

Power Saving Mini Crude Used Oil To Diesel Oil Refinery Plant | ||||||

Model Data | Working capacity | Dimension | Gross weight | |||

VBT-DD | 50-2500L/H | Model Choose | 5-65T | |||

Heating Method | Combustion machine | Fuel consume | Natural gas consume | |||

Natural gas/Gasoil/Coal/Power | 100.000Kcal | 2.0-5.6kg/hr | 3.0-6.0Nm3/h | |||

Power consume(Base) | Power onsume(heating) | Cooling mode | Cooling water volume (T) | |||

5-55KW | 18-522KW | Water cooling + air cooling, freezing liquid | 12-640T | |||

Rate of recovery | Heat exchange area | Working temperature | Working noise | |||

85%-93% | 10㎡ | (-10℃-360℃) | ≤60dB | |||

Voltage | Container specification | number of Container | 1Container | |||

220/380V(3PHASE) | 40HQ | 1Container | 1-4 | |||

Fuel supply | Light diesel fuels/Kerosenen/Heavy fuel oil/Environmental oil/Waste lube oil for burning(Molten salt furnace available) | |||||

The waste oil of 1400 PPM sulfur content can be distilled with a desulfurizing agent and a catalyst to obtain a waste oil of 100-150 ppm sulfur content. The original cetane number is 45, after distillation, you can get cetane number of 51~55. | ||||||

ADVANTAGE

1. High recovery rate of 83%to 95%. The base oil SN75-SN350 is about 82-88%, the mixture of diesel and gasoline is 5%, and the

sludge is about 5%.

2. Low cost, the cost per ton of used lube oil is about 30 dollars , 1 kind of catalyst needed only, percentage:1%-3%,through catalyzing,the harmful substances are selectively processed,for example,sludge is about 5%.

polymerization, shielding, passivation effect and discharged as residues.

3. Easy to operate,PLC control system, only 1-2 workers can operate

4. Handle different oils.diesel oil, engine oil, various engine oils, almost all waste lubricating oil.

5. Environmental protection, no harmful gas is produced, colloids, oxides, etc. in waste engine oil will become sludge, which can be used as fuel and asphalt.

Certification: ISO9001:2008, SGS, CE,BV.

6.Free design of fixtures as customers required.

7.12 months guarantee for product quality. (People damaged parts are charged)

7.12 months guarantee for product quality. (People damaged parts are charged)

8.Provide commissioning operation video.

9.White water color,about No.0.1-0.2 without bad smell and close to API II.

Refned oil

Vbolt oil distillation machine could reduce the carbon residue value for diesel oil, and increase the antioxidant stability and viscosity-temperature properties of it; the saturated hydrocarbon content also could be increased; and the color of base oil could be NO.0.1~NO 0.5 like water color and can directly used for lube oil and other engine oil.

Free sample test

VBOLT provide free sample test,we won't charge.Customers just need send your oil sample to us and tell us your requirements,we will make experiments for you and do not need any fees.

So what are you waiting for?

So what are you waiting for?

Don't hesitate to send us your waste oil for experiment!!

This is one of oil test report we made for England customer.

This is one of oil test report we made for England customer.

Visiting Customers

Cooperative customers

Our VBOLT has specialised in Oil Recycling Machine for more than 10 years.Our best sulfur level is 8ppm.

We have sold the machine to Southeastern AsiaNorth ,America,South America,Africa,Europe.

We have sold the machine to Southeastern AsiaNorth ,America,South America,Africa,Europe.

FAQ