Переработка используемого масла в дизельном двигателе машина для переработки масляного

- Категория: Machine Oil Purifier >>>

- Поставщик: Xinxiang,Huayin,Renewable,Energy,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 53550.29 $* | 56228.54 $* |

| Aug-15-2025 | 53100.55 $* | 55755.73 $* |

| Jul-15-2025 | 44550.99 $* | 46778.4 $* |

| Jun-15-2025 | 52200.59 $* | 54810.98 $* |

| May-15-2025 | 45450.34 $* | 47723.98 $* |

| Apr-15-2025 | 51300.30 $* | 53865.18 $* |

| Mar-15-2025 | 50850.19 $* | 53393.87 $* |

| Feb-15-2025 | 50400.35 $* | 52920.54 $* |

| Jan-15-2025 | 49950.25 $* | 52448.86 $* |

Характеристики

Founded in 1993, Xinxiang Huayin Renewable Energy Equipment Co., Ltd is a leading manufacturer of large and small scale waste tire & plastic pyrolysis plants and pyrolysis oil/engine oil distillation plant. These projects convert thousands of kilograms of waste plastic & tire into high quality fuel oil or diesel. Huayin technology is economically viable & environmentally compliant. Huayin Equipment is ISO 9001:2008 certified and CE Certified.

Huayin Energy focuses on equipment manufacturing, project development and turnkey facility operations.

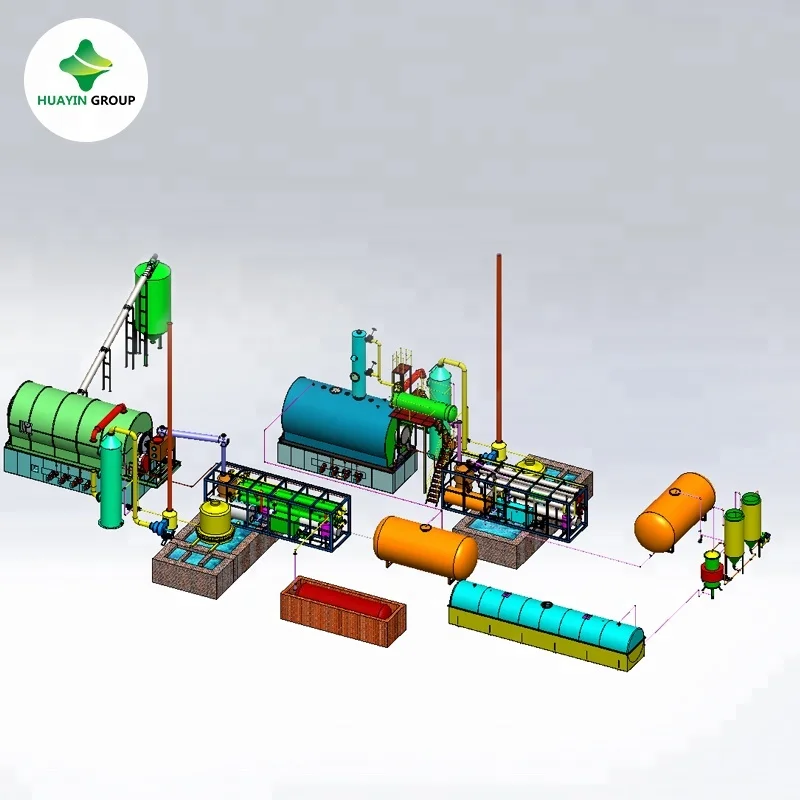

Thermal Decomposition Plants manufactured by HUAYIN are efficient at:

1. Solid Waste Management: processing of rubber and used tires, OTR tires, plastic waste and other hydrocarbons;

2. Liquid Waste Management: processing of waste muds, drilling solutions, oil sludge, waste engine oil, motor oil and lubricating oil;

3. Energy Recovery: MSW recycling to energy solution.

Huayin Group offers EPA Friendly and patent-pending system that meets or exceeds most countries' environmental standards. We are committed to bringing innovative ideas to the marketplace that redefine the way to recycle.

Below is our pyrolysis machine + distillation machine installed in Benin

Huayin has the technology to process waste engine oil, crude oil, pyrolysis oil, oil sludge materials to get diesel .

The Latest technology 5-30T oil distillation machine to diesel is amazing technical solution for different waste oil such as waste engine oil, pyrolysis oil, sludge oil, mud oil ,very thick dirty impurities oil . This technology is mainly to use steam generator to make steam which can have effection with oil gas to reduce pressure to vacuum level .then when the operation is going on, diesel can be produced at 300℃ -550℃ ,however, now the highest temperature is 300℃ -380℃ .in this way oil quality will be highly improved and also fuel can be used less.

This machine will need one-time catalyst which is produced by our company only, there is no need to buy from other catalyst factory as we have the catalyst formula .it is customized.

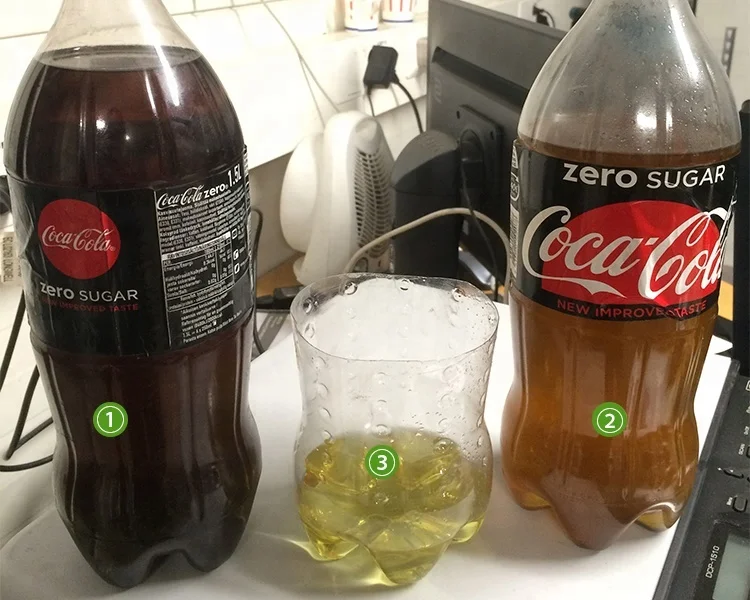

Collecting oil from the distillation machine , The yellow color oil is diesel oil after remove color and smell.

SPECIFICATION OF WASTE OIL DISTILLATION PLANT | ||

Capacity | 3 TON , 5 TON , 10 TON , 30 TON ... | |

Working type | batch type and contnuous type | |

Avaiable raw material | Pyrolysis oil ,used motor oil , furnace oil , mixed waste oil , hydrulic oil , sludge oil etc. | |

Heating fuel | coal , wood , pyrolysis oil , natural gas | |

Reactor raw material | Q245R steel plate , Q345R boiler steel plate or customized support | |

Machine landing area | 300-400 square meter (various by different capacity) | |

Operators | 2 workers per shift | |

Output product data

No. | End Production Name | oil yield | Usage |

1 | Diesel fuel | 85% | Used for diesel engines like trucks , tractors , ships ,power generators etc. |

2 | Residue oil | 9% | used for distillation machine as heating fuel |

3 | Syngas & impurities | about 6% | Recycled to distillation furnace as heating material |

Distillation plant works as follows:

1. Pump waste oil into distillation reactor by oil pump.

2. Heat the reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out first by controlling the temperature over 150 Celsius degrees.

3.The gasoline will be cooled out when the temperature is below 150 Celsius degrees, the rest of the system is same as pyrolysis system.

Item | Function |

Distilation reactor | The waste oil will be pumped into the reactor for refining. |

Distillation column | Atmospheric Fractionator Ensure differrent Fraction come Out. |

Condensing device | The oil gas will be cooled to liquid oil then flow to the oil storage tank |

Vacuum pump | Ensure the distillation machine working under normal pressure. |

Anti back fire device | Safety device , prevent the oil gas revert to the reactor. |

Non condensable oil gas recycling system | The non condensed oil gas (Syngas ) will be recycled to heating system as fuel. |

Color and smell removal system | the last step to remove bad smell and color to yellow diesel oil. |

Dedust system | 3 layers of ceramic packing dedusting to remove dust and acidity, non- pollution. |

Safety devices | Auto releasing pressure device , alarm, safety valve , etc to ensure safety operating. |

Huayin's plants have been exported to over 50 countries including india , Romania , Srilanka , Greece , Poland , Italy , Bulgaria , Chile , South Korea , Finland , Benin , indonesia , Thailand , England ...etc. over 50 countries.

The machine delivery from our factory .

The delivery time is 25 working days after received deposit .

1. Huayin's plants enjoy one-year guarantee, after which, we still offer lifelong technical support for your plant.

2.Our After-sales Service Department will pay you regular visits for any feedback, opinions or suggestions. For any question, just call:+86 371-55917087.

3.For any tiny plant problem you cannot solve after one-year guarantee finishes, please feel free to Email or call our salespeople, who will wholeheartedly help you solve your problem.

For problems that cannot be solved via email or phone-call, our engineers may be dispatched to do plant maintenance and debugging (which usually takes as short as one day) until your plant resumes normal operation. Such service shall be paid at your expense after one-year guarantee finishes.

Environment friendly

Energy-saving

Installation&worker training

Technical support&update

Service

training as well as Technical support&update Service.