Линия по производству мягких пакетов Iv-solution экономичный тип автоматическая машина для розлива жидкостей LVP IV без ПВХ запечатывание герметизация

- Категория: Filling Machines >>>

- Поставщик: Huizhou,Pingfang,Trading,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 41650.77 $* | 43733.23 $* |

| Aug-19-2025 | 41300.75 $* | 43365.45 $* |

| Jul-19-2025 | 34650.34 $* | 36383.12 $* |

| Jun-19-2025 | 40600.45 $* | 42630.89 $* |

| May-19-2025 | 35350.59 $* | 37118.34 $* |

| Apr-19-2025 | 39900.31 $* | 41895.95 $* |

| Mar-19-2025 | 39550.89 $* | 41528.27 $* |

| Feb-19-2025 | 39200.31 $* | 41160.89 $* |

| Jan-19-2025 | 38850.23 $* | 40793.47 $* |

Характеристики

Soft Bag Iv-solution Production Line Economical Type LVP IV Non-pvc Automatic Liquid Filling Machine Filling Sealing SUS304/316

Main Technical Terms & Function:

1. Up slide cylinder - driving the pin cylinder, the grab cylinder and the plug cylinder (manipulator) for a reciprocating motion in and out.

2. Pin cylinder - driving the filling pin for a reciprocating motion up and down.

3. Grab cylinder - driving the manipulator which grabbing the polycarbonate plug clamping or releasing.

4. Plug cylinder - making the manipulator a movement up and down.

5. Clamping cylinder- making a movement backward and forward, clamping or releasing the bag.

6. Releasing cylinder - releasing the bag, making a movement up and down.

7. Rotating cylinder - driving bagging feeding device for 45º rotation.

8. Sliding cylinder - driving the rotating cylinder and the bag feeding device for a movement backward and forward.

9. Proximity switch - the major component for the cylinder automatic controlling

10. Fiber optical sensors 1- detect the existence of bags.

11. Flow sensor – flow counting.

12. Vibrating disk - making the polycarbonate plug arranged automatically.

13. Vibrating screen- assist to make the polycarbonate plug arranged automatically.

14. Oil-water separator - assuring the air source clean and safe; it can be adjusted to the required pressure.

15. Solenoid valve – control the cylinder moving

16. Key switch - controlling the total power supply.

17. Emergency stop button -if there is a fault, press the button for emergency stop, cut off the operation.

18. PLC etc. – in the control box.

Main Technical Parameter

Power supply: AC220V±10%,50-60Hz;

Power input: 0.8kw (including vibrating disk) ;

Working pressure: Cylinder: 0.5-0.6MPa, Filling: 0.15-0.2MPa;

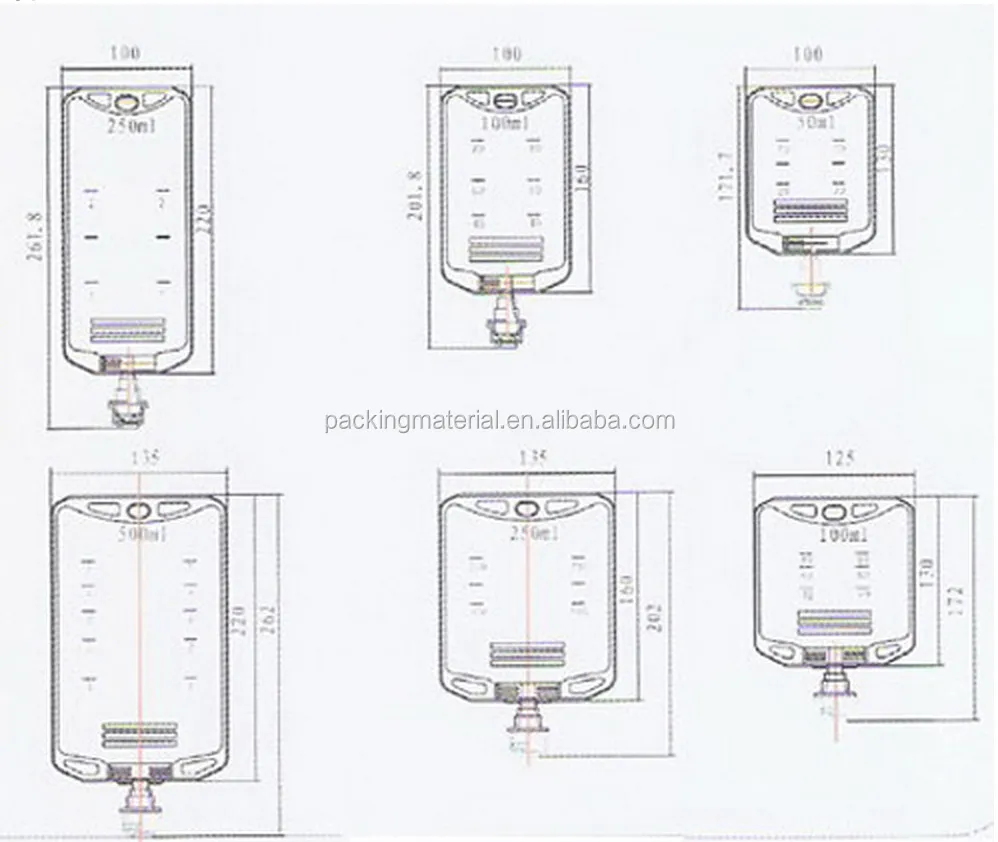

Filling capacity: 50-5000ml (adjustable);

Filling speed: 500-2500 BPH

Filling accuracy: ≤ 1.0 ± %

Flow transducer factor: 2100~3600

Using environment: Temperature: -10 ℃-65 ℃, humidity: ≤85%

Machine weight: 950kg (including vibrating disk)

Overall dimension: (L)1800×(W)1600×(H)1850mm

(Incl. vibration disk, conveyor, buffer tank)

We are using standard export plywood cases. To ensure that the transport process will not damage and safety arrived in customers' hands.

Company Introduction

Huizhou Pingfang pharmaceutical machinery co. ltd. is a professional manufacturer and supplier for pharmaceutical machinery, pharmaceutical packing material company, who is standing firmly with a good reputation in the industry of China pharmaceutical machinery.

Our company focus on fabricating efficient and technically sound pharmaceutical machines that meets or exceed our customer’ expectations. Our vast product selection caters to numerous industries, worldwide.

We are specializing in machinery including,

Pharmaceutical industry,

Food industry,

Chemical industry,

and provide customers with material, etc

Meanwhile, we can undertake turn key projects for conceptual design, process design, water treatment solutions, clean-room design, etc.

Customer service including technical support, installation & commissioning after sale.

Welcome all of friends from abroad to our company and establishing good business cooperation.

Workshop

Cooperation Case

Certificate

Installing and Commission:

We will install and test the machine in best working condition before shipment. If customer requires our technician to adjusting the machine and train technician at arrival place, we will send technician there. All our expenses including round-trip air ticket to the nearest airport, local conveyance to your factory, Lodging&Boarding expenses shall be payable by you. In case the stay of our technician, additional service fee will be charged .

Warranty period:

One year for fully machine guarantee. And in this year if the machine broken caused by mechanical problem, all of the spare part is free. The service of the machine all though the machine’s life.