Полностью автоматическая Взрывозащищенная битумная барабанная стальная цилиндрическая линия для 150л 200л 210л металлический барабан

- Категория: >>>

- Поставщик: Wuxi,Longterm,Machinery,Technologies,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 714000.48 $* | 749700.74 $* |

| Aug-15-2025 | 708000.18 $* | 743400.92 $* |

| Jul-15-2025 | 594000.94 $* | 623700.60 $* |

| Jun-15-2025 | 696000.13 $* | 730800.94 $* |

| May-15-2025 | 606000.72 $* | 636300.54 $* |

| Apr-15-2025 | 684000.6 $* | 718200.68 $* |

| Mar-15-2025 | 678000.72 $* | 711900.93 $* |

| Feb-15-2025 | 672000.97 $* | 705600.71 $* |

| Jan-15-2025 | 666000.28 $* | 699300.44 $* |

Характеристики

Fully Automatic Explosion Proof Bitumen Drum Steel Barrel Filling Line for 150L 200L 210L Metal Drum^

Product Overview

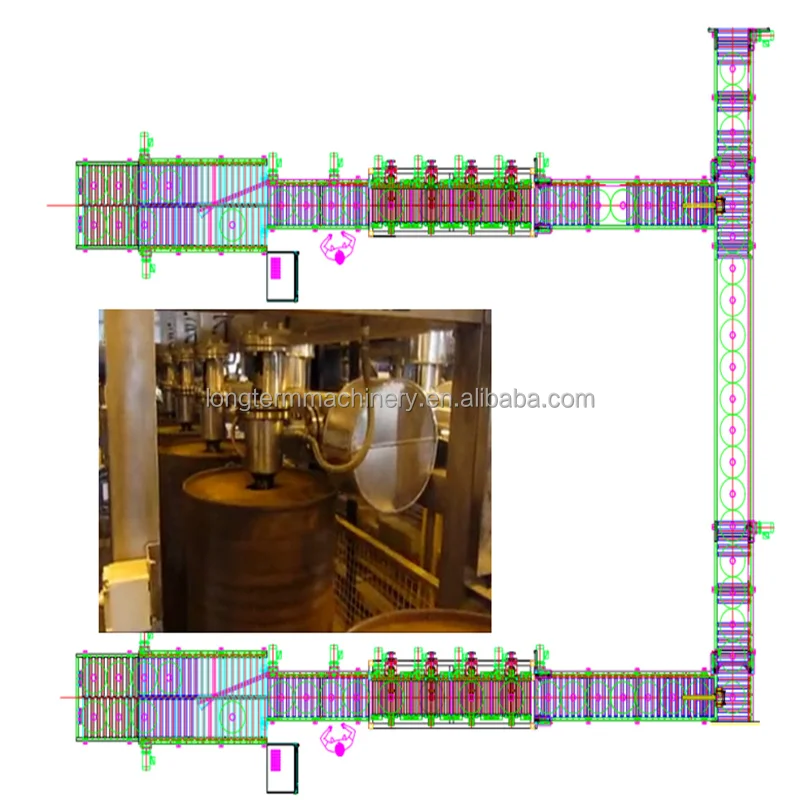

Introduction to Design Scheme

According to the characteristics of viscosity, temperature and density of customer materials, our technical research and

development department suggests to use the GZM-YCS series automatic flow quantitative filling machine (designed with 2 sub-loading heads) developed and produced by our company to complete the quantitative packing work. The contact material is made of 304 stainless steel, the other parts are made of high quality carbon steel, and all the materials pass through the pipeline with fast loading joints, which fully conforms to the requirements of chemical and oily liquid materials. At the same time, select well-known brand electronic, pneumatic components, PLC touch screen control man-machine interface, high measurement accuracy, beautiful appearance, exquisite processing, easy operation, low maintenance cost, The whole production line is equipped with bucket platform / vertical clamping channel / automatic filling / manual cover / pneumatic cover/automatic separation / forklift handling / automatic transportation production line.

According to the characteristics of viscosity, temperature and density of customer materials, our technical research and

development department suggests to use the GZM-YCS series automatic flow quantitative filling machine (designed with 2 sub-loading heads) developed and produced by our company to complete the quantitative packing work. The contact material is made of 304 stainless steel, the other parts are made of high quality carbon steel, and all the materials pass through the pipeline with fast loading joints, which fully conforms to the requirements of chemical and oily liquid materials. At the same time, select well-known brand electronic, pneumatic components, PLC touch screen control man-machine interface, high measurement accuracy, beautiful appearance, exquisite processing, easy operation, low maintenance cost, The whole production line is equipped with bucket platform / vertical clamping channel / automatic filling / manual cover / pneumatic cover/automatic separation / forklift handling / automatic transportation production line.

FEATURES AT A GLANCE

Design Index of Filling Production Line

* Packaging container: 150 and 180KG chemical iron drums.

* Filling nozzles:16 nozzles

* Filling range :150 and 180KG Drum

* Production capacity :60-70 drum per hour/per nozzle.

* Filling accuracy : ±0.2% repeat filling accuracy

* Packaging Material: Chemical Resin

* Packaging container: 150 and 180KG chemical iron drums.

* Filling nozzles:16 nozzles

* Filling range :150 and 180KG Drum

* Production capacity :60-70 drum per hour/per nozzle.

* Filling accuracy : ±0.2% repeat filling accuracy

PRODUCT SPECIFICATIONS

No. | Name | Part Name | Specification Type | Unit | Quantity (single set of equipment) | Manufacturers |

1 | Drum loading conveyor | Roller conveyor | 700-60-2 | pcs | 5 | Shanghai |

2 | Filling machine | Photoelectric sensor | E3Z-T61A | set | 5 | Omron |

3 | Air switch | Schneider | OSMC32N | set | 3 | Schneider |

4 | Relay | Schneider | RXM2LB2BD | set | 5 | Schneider |

5 | Proximity switch | Proximity switch | set | 3 | Omron | |

6 | Solenoid valve | Solenoid valve | TGX08 | set | 5 |

PRODUCT CONFIGURATION

Explosion Proof Device

Control System:

Industrial computer PLC control system, electronic, pneumatic integration, intelligent color touch screen man-machine

Industrial computer PLC control system, electronic, pneumatic integration, intelligent color touch screen man-machine

interface, simple and fast.

SMART LINE Touch Screen

The SIMATIC SMART LINE panel accurately provides the standard functions of the man-machine interface, is economical and

applicable, and has a high cost performance. Now, the function of a new generation of wonderful series of panels-SMART LINE V3 has been greatly improved, and it forms a perfect automation control and human-computer interaction platform with PLC, which provides an ideal solution for your convenient control.

applicable, and has a high cost performance. Now, the function of a new generation of wonderful series of panels-SMART LINE V3 has been greatly improved, and it forms a perfect automation control and human-computer interaction platform with PLC, which provides an ideal solution for your convenient control.

SIMATIC S7-1200

SIMATIC S7-1200 is a compact, modular PLC that can complete tasks such as simple logic control, advanced logic control, HMI and network communication. The perfect solution for stand-alone small automation system. It is easy to design and implement automationsystems that require network communication functions and single-screen or multi-screen HMI. It has advanced application functions supporting small motion control systems and process control systems. Simple but highly accurate automation tasks can be realized.

It has realized a modular and compact design with powerful functions. The design with strong scalability and high flexibility can realize the communication interface of the highest standard industrial communication and a set of powerful integrated technical functions, making the controller an important part of a complete and comprehensive automation solution.

It has realized a modular and compact design with powerful functions. The design with strong scalability and high flexibility can realize the communication interface of the highest standard industrial communication and a set of powerful integrated technical functions, making the controller an important part of a complete and comprehensive automation solution.

GZ-YCS-1501 automatic single-row quantitative filling machine

Configuration software system

It is a new type of industrial automatic control system that replaces the traditional closed system with an integrated system composed of standard industrial computer software and hardware platforms. It has the advantages of strong adaptability, good openness, easy expansion, economy, and short development cycle.

Drum outlet conveyor

According to the filling quantity, the drum conveyer meets the filling continuous drum. Conveyor adopts roller, effectively reduce

running resistance, noise, easy to transport. According to the process requirements, the conveyor passes through the filling room

The photoelectric detection filling drum stops, waits for the rotary cover according to the set time, reaches the waiting time of the rotary cover, the conveyor starts automatically, and the filling drum is fed into the sub-drum position.

running resistance, noise, easy to transport. According to the process requirements, the conveyor passes through the filling room

The photoelectric detection filling drum stops, waits for the rotary cover according to the set time, reaches the waiting time of the rotary cover, the conveyor starts automatically, and the filling drum is fed into the sub-drum position.

Material: Carbon steel spray

Dimensions :1.5 m*1.4m*0.4m

Ø76 double-stranded galvanized roller

Velocity :10 m/min

Dimensions :1.5 m*1.4m*0.4m

Ø76 double-stranded galvanized roller

Velocity :10 m/min

SALES AND SERVICE NETWORK

Successful Project

Package

FAQ

Q1: Are you a Manufacturer or Trading company?

A1: We are the manufacturer from Jiang Su,so we can offer the best quality and price of the machine to you.

Q2: How can I install this Bitumen Filling Machine when it arrives?

A2:We will send the instruction manual and some video to help you install the machine.You can talk with our engineer by video chat or we will arrange site engineers to install and commissioning machine.

Q3: What is the cost to send installation/training staff? How many staff do you need to send?

A3: Whole installation/traning process needs 3 engineers. Around 15 days. Round-air ticket, local

transpotation, accomodation, food, and 100USD/day/person.

A1: We are the manufacturer from Jiang Su,so we can offer the best quality and price of the machine to you.

Q2: How can I install this Bitumen Filling Machine when it arrives?

A2:We will send the instruction manual and some video to help you install the machine.You can talk with our engineer by video chat or we will arrange site engineers to install and commissioning machine.

Q3: What is the cost to send installation/training staff? How many staff do you need to send?

A3: Whole installation/traning process needs 3 engineers. Around 15 days. Round-air ticket, local

transpotation, accomodation, food, and 100USD/day/person.