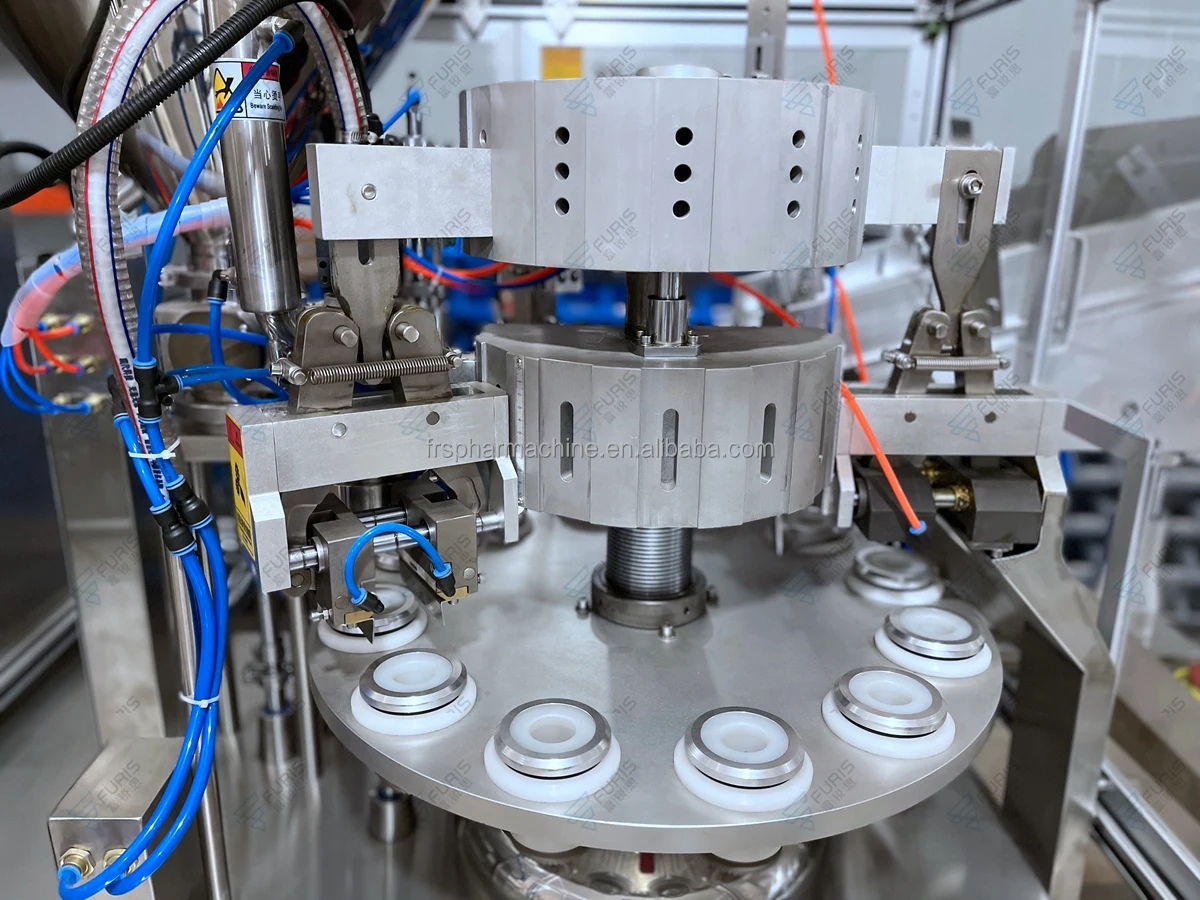

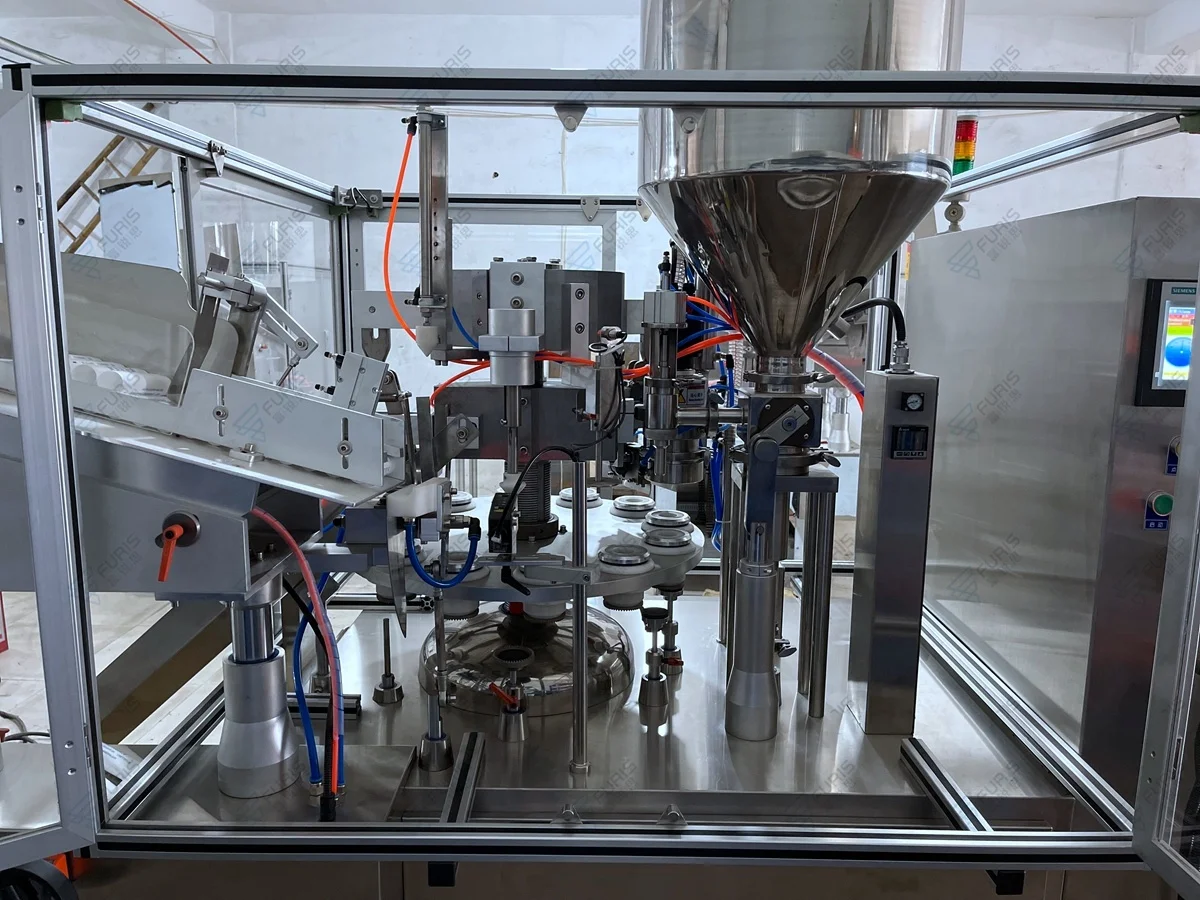

Автоматическая машина для наполнения и запечатывания трубок из мягкого алюминия 12 рабочих станций 60 шт. в

- Категория: >>>

- Поставщик: Ruian,Furis,Import,&,Export,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.40 $* | 0.92 $* |

| Aug-15-2025 | 0.80 $* | 0.14 $* |

| Jul-15-2025 | 0.7 $* | 0.5 $* |

| Jun-15-2025 | 0.92 $* | 0.54 $* |

| May-15-2025 | 0.68 $* | 0.19 $* |

| Apr-15-2025 | 0.34 $* | 0.13 $* |

| Mar-15-2025 | 0.19 $* | 0.56 $* |

| Feb-15-2025 | 0.79 $* | 0.26 $* |

| Jan-15-2025 | 0.15 $* | 0.46 $* |

Характеристики

Product Overview

FRS full auto semi auto capsule filling machine

This machine is used for filling the powder or pellet liquid oil into the empty gel capsule.it is a good idea for small pharma medicine company,our machine mainly export to the USA.We also can offer you the full line for packing the capsule into bottle or blister.

Features

1.Transmission parts enclosed in the platform below the safe, reliable, non-polluting; filling and sealing part of the

installation within the platform above a semi-closed static-frame visual plexiglass cover, easy to observe, easy to operate, easy

to maintain;

2.Main parts adopt import parts, PLC control system (Siemens), color touch screen dispaly (Siemens), invertor: (Panasonic, Japan),

low electric applicator (Omron), pneumatic parts (Airtac, Taiwan), motor: (STS, Taiwan)

3.Automatically feeding tube into tube holder

4.The photoelectric target-aiming working station employs accurate detector and marching type motor,ensuring the tube design at

the correct position.

5.Filling nozzle enters tube inside to fill.As it fills it will moves up and prevent material from over flowing and spilling.

Has auto cutting tube tail function when finishing fill the material into the tube.

6.No tube no filling,Sealing temperature adopt (Leister hot air gun) inside heating for the tail of tube and cooling device for

out of tube.

7.Automatically printing the character code on the tube bottom.

8.Has overload protection

9.Has accounting and auto stop machine when reach the number

installation within the platform above a semi-closed static-frame visual plexiglass cover, easy to observe, easy to operate, easy

to maintain;

2.Main parts adopt import parts, PLC control system (Siemens), color touch screen dispaly (Siemens), invertor: (Panasonic, Japan),

low electric applicator (Omron), pneumatic parts (Airtac, Taiwan), motor: (STS, Taiwan)

3.Automatically feeding tube into tube holder

4.The photoelectric target-aiming working station employs accurate detector and marching type motor,ensuring the tube design at

the correct position.

5.Filling nozzle enters tube inside to fill.As it fills it will moves up and prevent material from over flowing and spilling.

Has auto cutting tube tail function when finishing fill the material into the tube.

6.No tube no filling,Sealing temperature adopt (Leister hot air gun) inside heating for the tail of tube and cooling device for

out of tube.

7.Automatically printing the character code on the tube bottom.

8.Has overload protection

9.Has accounting and auto stop machine when reach the number

Product Paramenters

SPECIFICATIONS FOR FRS-60 AUTOMATIC TUBE FILLING AND SEALING MACHINE | ||||||

1 | Model | / | FRS-60 | |||

2 | Voltage | / | 220V/380V 50-60Hz | |||

3 | Productivity | pcs/min | 40-60 | |||

4 | Filling volume | ml | 3-300 | |||

5 | Tube diameter | mm | 10-50 | |||

6 | Tube length | mm | 50-250 | |||

7 | Max power | kw | 3 | |||

8 | Water cousumption | L/min | 3-6 | |||

9 | Machine weight | kg | 2100kg | |||

10 | Dimension(L*W*H) | mm | 1900*800*1600mm | |||

Recommend Products

NJP-260 liquid capsule filling machine FRS-8 Capsule counting machine DPB-250 Blister packing machine

Customer Photos

Certifications

Company Profile

FAQ

Q: Are you a factory or a trading company?

A: We have own factory manufacturing pharma machine and packaging machines and we provide perfect OEM and after-sale service.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.before ship the machine,we will let the machine run one week in our factory.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments.Pay 30%deposit after when finish the machine you can pay the balance before shipping.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Q:How is your machine quality?

More than 15 years manufacturing experience,with rich experience engineer and good CNC machine to make the with machine stable performance and high quality ,with good quality and competitive price let our machines with good comment from our customers,now our machines mainly export to north American and western Europe.

Q:How is the machine guarantee and after service?

One year guarantee,in one year,if the spare parts break,we can send the new spare parts for free but the customer need pay the express fee.

Q:How is the after service?

We have several technicians who gets passport ready to travel all over world to offer service to you.have 24hours hot line for Technical Support.We get 18hours internet line for technical support. Video camera in workshop to help you adjust and solve machine problem in working situation.We have many agents can offer the technical support in local place all over the world.

Our advantages

1. High quality + Economical Solution

Furis Group with China technology support match up your high quality requirements.

Furis Group economical price can provide you better budget control.

Furis Group strict quality control with ISO 9001 certification CE certification and other qualification can guarantee you avoiding any risk in machine selection or project implementation.

2. Professional Turnkey Project

Furis Group GMP experts and validation engineers can guide your project and documents match up the WHO GMP.EU GMP USA,etc

FRS factory general planning experts can ensure your project not only quality in all aspects,but also cost efficiency flexibility and expandability and security.

Furis Group professional designing and experienced engineering team can support your project optimal implementation saving labor time and cost.

3. One-stop Technical Service

Furis Group with worldwide partners can provide you current technology and know how of machine project validation and production.

FRS Mechanical and electrical engineers can make custom-made design to match up user's requirement specification.

and manufacturing according to European standard.

HM Energetic and professional team can provide you effectively one-stop technical service from sample trial testing

FAT,installation commissioning,SAT,training to documentation and validation.

A: We have own factory manufacturing pharma machine and packaging machines and we provide perfect OEM and after-sale service.

Q: How can I know your machine works well?

A: Before delivery, we shall test the machine working condition for you.before ship the machine,we will let the machine run one week in our factory.

Q: How can I know your machine is designed for my product?

A: You can send us samples of your product and we test it on machine.

Q: How can I pay my order?

A: We accept T/T, Western Union, Alibaba Trade Assurance payments.Pay 30%deposit after when finish the machine you can pay the balance before shipping.

Q: Do you have a CE certificate?

A: For every model of machine, it has a CE certificate.

Q:How is your machine quality?

More than 15 years manufacturing experience,with rich experience engineer and good CNC machine to make the with machine stable performance and high quality ,with good quality and competitive price let our machines with good comment from our customers,now our machines mainly export to north American and western Europe.

Q:How is the machine guarantee and after service?

One year guarantee,in one year,if the spare parts break,we can send the new spare parts for free but the customer need pay the express fee.

Q:How is the after service?

We have several technicians who gets passport ready to travel all over world to offer service to you.have 24hours hot line for Technical Support.We get 18hours internet line for technical support. Video camera in workshop to help you adjust and solve machine problem in working situation.We have many agents can offer the technical support in local place all over the world.

Our advantages

1. High quality + Economical Solution

Furis Group with China technology support match up your high quality requirements.

Furis Group economical price can provide you better budget control.

Furis Group strict quality control with ISO 9001 certification CE certification and other qualification can guarantee you avoiding any risk in machine selection or project implementation.

2. Professional Turnkey Project

Furis Group GMP experts and validation engineers can guide your project and documents match up the WHO GMP.EU GMP USA,etc

FRS factory general planning experts can ensure your project not only quality in all aspects,but also cost efficiency flexibility and expandability and security.

Furis Group professional designing and experienced engineering team can support your project optimal implementation saving labor time and cost.

3. One-stop Technical Service

Furis Group with worldwide partners can provide you current technology and know how of machine project validation and production.

FRS Mechanical and electrical engineers can make custom-made design to match up user's requirement specification.

and manufacturing according to European standard.

HM Energetic and professional team can provide you effectively one-stop technical service from sample trial testing

FAT,installation commissioning,SAT,training to documentation and validation.