Машина для переработки пиролизного масла из отработанного

- Категория: Machine Oil Purifier >>>

- Поставщик: Xinxiang,Huayin,Renewable,Energy,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 77350.56 $* | 81218.12 $* |

| Aug-15-2025 | 76700.93 $* | 80535.44 $* |

| Jul-15-2025 | 64350.48 $* | 67568.21 $* |

| Jun-15-2025 | 75400.36 $* | 79170.74 $* |

| May-15-2025 | 65650.31 $* | 68933.85 $* |

| Apr-15-2025 | 74100.47 $* | 77805.80 $* |

| Mar-15-2025 | 73450.90 $* | 77123.64 $* |

| Feb-15-2025 | 72800.88 $* | 76440.8 $* |

| Jan-15-2025 | 72150.9 $* | 75758.33 $* |

Характеристики

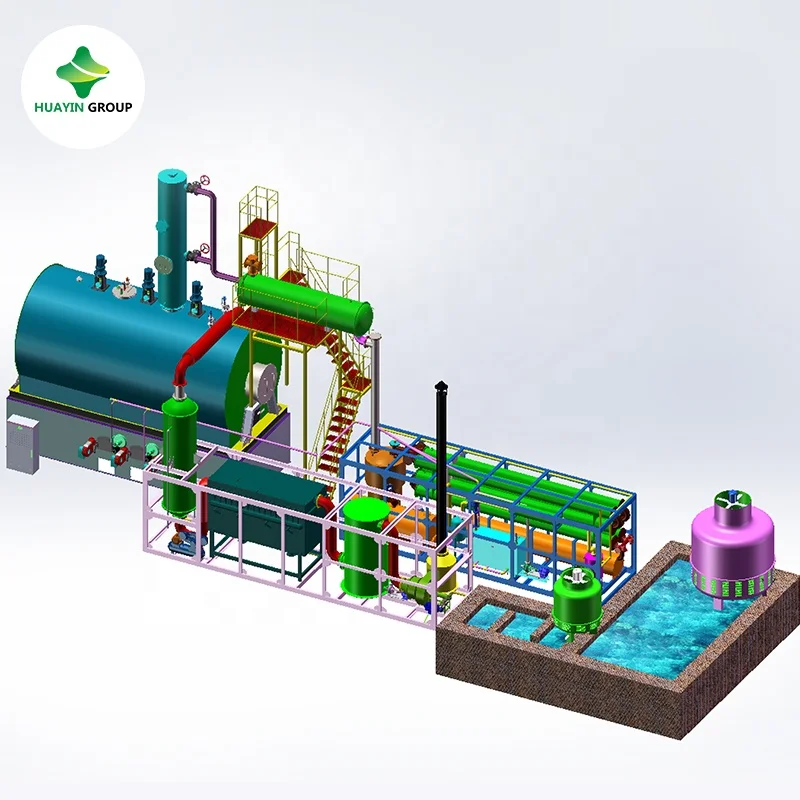

Waste plastic pyrolysis oil distillation machine refining machine

Waste engine oil/pyrolysis oil can be refined into valuable diesel oil through catalytic cracking and high temperature distillation technology. It is a method of separating mixtures based on differences in volatilities of components in a boiling liquid mixture. After being distilled by the distillation plant, the oil may have dark color with bad smell, then we suggest to deep purify the oil, with Huayin matched color and smell removal system, you will get clean diesel oil as final products with beautiful light yellow color.

Waste oil refining plant distills the incoming crude oil, waste oil or lubrication oil into useful products such as diesel oil and fuel oils, gasoline or petrol, jet fuel, etc, the oil yield will be 85%-90%, the by-products are 10%-15% slag and syngas.

Distillation plant works as follows:

1. Pump waste oil into distillation reactor by oil pump.

2. Heat the reactor, and the liquid oil will slowly become oil gas, oil gas will go through catalytic chamber and condenser, then diesel will be cooled out first by controlling the temperature over 150 Celsius degrees.

3.The gasoline will be cooled out when the temperature is below 150 Celsius degrees, the rest of the system is same as pyrolysis system.

Waste plastic pyrolysis oil distillation machine refining machine

Below is our distillation machine installed in Benin

The Latest technology 5-30T oil distilaltion machine to diesel is amazing technical solution for different waste oil such as waste engine oil, pyrolysis oil, sludge oil, mud oil, very thick dirty impurities oil . This technology is mainly to use steam generator to make steam which can have effection with oil gas to reduce pressure to vacuum level .then when the operation is going on, diesel can be produced at 300℃ -550℃ ,however, now the highest temperature is 300℃ -380℃ .in this way oil quality will be highly improved and also fuel can be used less.

This machine will need one-time catalyst which is produced by our company only, there is no need to buy from other catalyst factory as we have the catalyst formula .it is customised.

SPECIFICATION OF WASTE OIL DISTILLATION PLANT | ||

Capacity | 3 TON , 5 TON , 10 TON , 30 TON ... | |

Working type | batch type and contnuous type | |

Avaiable raw material | Pyrolysis oil ,used motor oil , furnace oil , mixed waste oil , hydrulic oil , sludge oil etc. | |

Heating fuel | coal , wood , pyrolysis oil , natural gas | |

Reactor raw material | Q245R steel plate , Q345R boiler steel plate or customized support | |

Machine landing area | 300-400 square meter (various by different capacity) | |

Operators | 2 workers per shift | |

Output product data

No. | End Production Name | oil yield | Usage |

1 | Diesel fuel | 85% | Used for diesel engines like trucks , tractors , ships ,power generators etc. |

2 | Residue oil | 9% | used for distillation machine as heating fuel |

3 | Syngas & impurities | about 6% | Recycled to distillation furnace as heating material |

Item | Function |

Distilation reactor | The waste oil will be pumped into the reactor for refining. |

Distillation column | Atmospheric Fractionator Ensure differrent Fraction come Out. |

Condensing device | The oil gas will be cooled to liquid oil then flow to the oil storage tank |

Vacuum pump | Ensure the distillation machine working under normal pressure. |

Anti back fire device | Safety device , prevent the oil gas revert to the reactor. |

Non condensable oil gas recycling system | The non condensed oil gas (Syngas ) will be recycled to heating system as fuel. |

Color and smell removal system | the last step to remove bad smell and color to yellow diesel oil. |

Dedust system | 3 layers of ceramic packing dedusting to remove dust and acidity, non- pollution. |

Safety devices | Auto releasing pressure device , alarm, safety valve , etc to ensure safety operating. |

Huayin's plants have been exported to india , Romania , Srilanka , Greece , Poland , Italy , Bulgaria , Chile , South Korea , Finland , Benin , indonesia , Thailand , England ...etc. over 50 countries.

Our Advantage

2.Latest integrated design condensing system , 36 meters condensing pipes ,more cooling area, more effective cooling effect, higher oil yield

3.Equipped with safety valves, auto alarming system, anti-explosion valve, which will guarantee 100% safety

4. Flue tube condenser, cool down the exhaust gas from the burner, protect draft fan and improve dedusting effects.

5. Adopts ceramic packing Three-layer dedusting system to clean the exhaust gas to reach European pollution control standards.

6.Automatic submerged welding technology, ultrasonic nondestructive testing, guarantee the equipment quality

7.Oil pump feeding and discharging, save much manpower.

Environment friendly

Energy-saving

Installation&worker training

Technical support&update

Service

training as well as Technical support&update Service.