Линия по производству заказанного молока/блок обработки молока/Пастеризатор

- Категория: Станки для переработки молока >>>

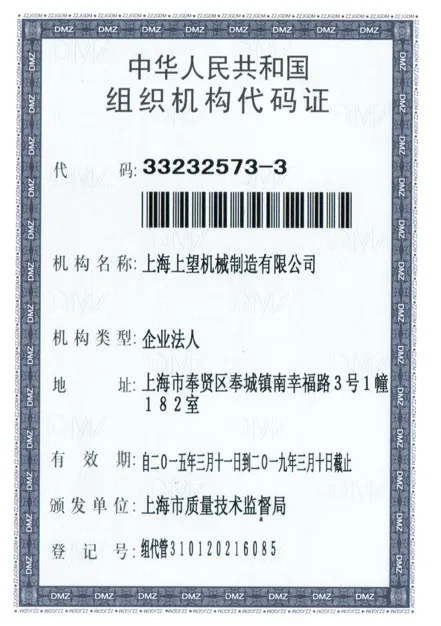

- Поставщик: Shanghai,Shangwang,Machinery,Manufacturing,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.93 $* | 0.55 $* |

| Aug-16-2025 | 0.31 $* | 0.35 $* |

| Jul-16-2025 | 0.0 $* | 0.2 $* |

| Jun-16-2025 | 0.77 $* | 0.20 $* |

| May-16-2025 | 0.20 $* | 0.32 $* |

| Apr-16-2025 | 0.84 $* | 0.61 $* |

| Mar-16-2025 | 0.81 $* | 0.72 $* |

| Feb-16-2025 | 0.97 $* | 0.55 $* |

| Jan-16-2025 | 0.54 $* | 0.77 $* |

Характеристики

Dairy pasteurized milk production line

Capacity of plant: 2MT~100MT per day

The whole milk production line consists of the following units:

1. Milk Reception or Powder Dissolving Mixing Section

2. Mixing and Sugar Melting Section

3. Pasteurizer and Homogenizer

4. Milk Storage or Yogurt Producing Unit

5. Filling or Packing Unit

6. CIP Cleaning Systems

7. After Treatment Equipment, like conveyor, package or pallet, etc.

8. There are other assistant equipments used such as steam boilers, air compressor, cold water unit, etc.

9. Installation materials for the process pipline, utility pipeline as well as electrical installation are provided.

**Filling types can be decided by the customer then designed accordingly.

Our company can design customized milk production lines in accordance to the customers' requirements.

Material | SUS304/SUS316L |

Capacity | 1000L/H~20T/H |

Voltage | Customzied |

Application | Juice, Milk, yogurt |

Power | 2.95kw~15kw |

Max Sterilizing Temperature | 65℃~138℃ |

Steam Control system

Steam Control System is an inportant part of Pasterurizer, It contains steam rate adjustable valve, plunger valve, steam pressure reducing valve, steam trap and steam filter. A good steam control system can guarantee the machine working stable. All of the steam valves are come from Spirax Sarco (England).

Control Panel

Created for operators of every experience level, our integrated automation software is connected to a 10.1" touch screen interface, which gives operators an overview of the pasteurizer, including temperatures, pressures etc. Its performance is displayed in real time and, if there is a fault, the operator receives an immediate alert. If the automation solution is integrated in the line, the whole line can be viewed from one interface.

Divert System

The temperature of the product is verified both before and after the holding cell. Product can only continue out of the pasteurizer if it has been heated to the right temperature and held for the right length of time in the holding cell. If this is not the case, a signal is automatically sent to the divert valve, and the product is diverted back to the balance tank for recirculation.

Smart Balance Tank

A smart balance tank equipped with CIP washing ball, high level/low level transmitter. When the product at high level in the balance tank, the feeding pump will automaticlly stop. When the product at low level in the balance tank, the product pump will automaticlly stop.

FAQ

Q1: Are you a trading company or a manufactory

A1: We are the manufacture of water/beverage packing machine and water treatment equipment over 5years.We just not only sell machines, we sell our brand and service.

Q2: Do you have technical support after we purchased your machines?

A2: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q3: If you buy our machines, can you offer us wear-out spare pats?

A3: We provide our high quality machine 1 years guarantee , and we will also offer you 1 years wear-out spare parts for free. Once your machines broken or doesn't work within 1 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.

Name | Nimo Yu |

Adress | China (Mainland)ShanghaiShanghaiXingfu Road No.3, Fengxian District |

Whatsapp | +8615700091445 |

Wechat | +8615700091445 |