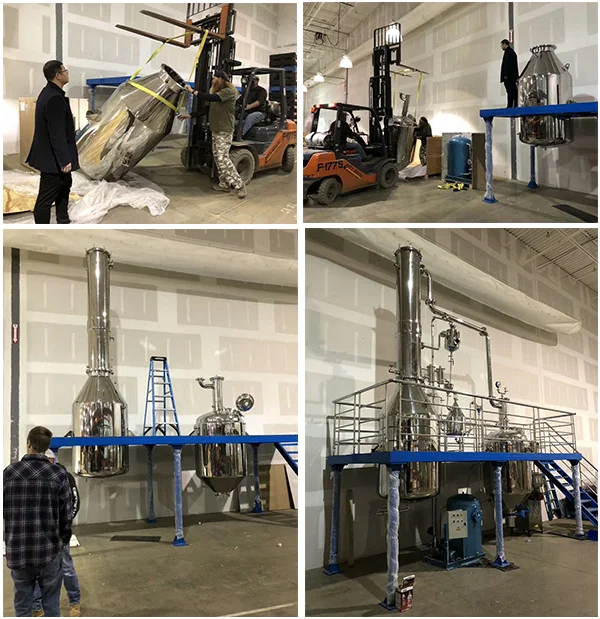

Установка для дистилляции эфирного масла vetivert 1000

- Категория: Machine Oil Purifier >>>

- Поставщик: Wuhan,HDC,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.66 $* | 0.31 $* |

| Aug-17-2025 | 0.14 $* | 0.5 $* |

| Jul-17-2025 | 0.84 $* | 0.67 $* |

| Jun-17-2025 | 0.8 $* | 0.19 $* |

| May-17-2025 | 0.77 $* | 0.5 $* |

| Apr-17-2025 | 0.80 $* | 0.57 $* |

| Mar-17-2025 | 0.36 $* | 0.36 $* |

| Feb-17-2025 | 0.95 $* | 0.15 $* |

| Jan-17-2025 | 0.65 $* | 0.70 $* |

Характеристики

Product introduction of essential oil distillation equipment:

HDC brand,essential oil steam distillation,advanced and Continuously improving .We had specialized in essential oil extracting technology and equipment for more than 30 years,serviced for thousands of customers all over the world.we hope to bring customers extraordinary experience and sincerely hope to serve you.

Application of essential oil distillation equipment:

This essential oil distillation equipment is popular,famous,advanced and with top quality in production of Chinese medicines,health products,biological drugs,cosmetics and food .This essential oil Distill equipment uses technology and chemical separation,can extract plant components efficiently by steam distillation , have good effect in collecting essential oil from plants.

Main advantage essential oil extraction equipment:

(1)Advance technology:automatic operation,more convenient and safer when running operation

(2)Saving space: needn't large hoisting equipment for installation and operation

(3)High efficiency. Pressure device in kettle can shorten the distillation time,4-6 hours finish one batch.

( 4 )Easy operation. One people can operate this machine easily .

Oil quality

Model | LSZL-1 | ||

Distillation kettle volume L | 1000 | ||

Kettle inside design pressure Mpa | 0.09 | ||

Heating area m2 | 3 | ||

condenser system m2 (condenser +cooler) | 5 | ||

Feed port diameter(mm) | 400 | ||

Oil-water separator(fermentor)L | 60 | ||

Length | 7500 | ||

Width | 2600 | ||

Height | 5500 | ||

Evaporation capacity (kg/h) | 150 | ||

Structure type:The device consists of inverted vertebral distillation kettle, demister, condensing tower, oil-water separator, double filter, supercharger, material conveyor belt and essential oil, pure dew collection tank, pure dew storage tank, food grade pump and other related pipelines composition. Equipment internal surface polishing Ra≤0.6μm,Outer surface matte treatment Ra≤0.8μm,To ensure that no health dead ends, in line with GMP requirements.

Distillation kettle | Effective volume: 1000L, using high-pressure steam through heating. Inside: working pressure: normal pressure;design temperature:120℃,work temperature≤100℃.Working medium:water; Upper oval headδ=6mm/S30408,Cylinder δ=6mm/S30408. Sewage valve:DN200, |

Demister | Size Φ300×750,δ=3mm/S30408,Demister inside has baffle, The top of the demister is set to the quick opening hole. Demister to facilitate cleaning.Meet the GMP requirements. |

Condenser | vertical coil condenser |

Steam distributor | Three-dimensional steam distributor, a more thorough steam through the material, improve the yield and quality of essential oils. |

Oil water separator | Stainless steel tank,Glass as the cup,Dedicated oil - water separator. Volume: 100L,size δ=3mm/S30408. |

Double filter | 120 mesh filter,flow 6.0m3/h,material S30408. |

The essential oil distillation equipment can be selected according to the residue of raw materials.

●The discharge valve of distillation equipment is very important. Different materials and different distillation methods should be used to select different discharge valves.

Dregs of water distillation, use butterfly valve valve discharge.

Water distillation (steam distillation) slag discharge, the large diameter pneumatic valve discharge, side manhole slag, hanging basket slag.

Raw material

We will assemble and the test machine before packing.also send English manual brochure.we will provide one engineer to assemble and train workers.

Our customers

Our service

Warranty Period:

* Free replacement of wearing parts in 6 months from the date of purchasing;

* Free replacement of main body in 12 months from the date of purchasing.

After-sale service:

1. Free replacement of wearing parts in 6 months from date of purchasing

2. We provide spare parts all year around at factory cost.

3. We provide technical solutions for clients at any time.

Our certification

Q1: What is the Warranty for the machines?

A1: 1 year for free.

Q2: What is the Material?

A2: Stainless steel.

Q3: When can I get the price?

A3: Within 24 hours, if urgent, please directly call us.

Q4: Whether the machine price can be more discount?

A4: In general, our MOQ is 1set with very reasonable price, but if large order, we also can apply to our Manager to appropriately give you a little discount.

Q5: How to ask quotation?

A5: Please note us what type of raw materials , and how many kgs of raw materials you want to treat per batch, then we will send you quotation as soon as we can.

Q6: Can we ask the oil plant for different types of oil?

A6: Yes, but we recommend no more than 3 different types.

Q7: Essential oil plants require how large of a workspace?

A7: The land area typically depends on the capacity of the plant. We can suggest an appropriate space to prepare after given specifications, or, can design the oil plant in-house specifically to the amount of workspace available.

Q8: How long will it take to receive my products?

A8: As a general rule, it will take one Month for us to produce.

Q9: Do you offer oversea installation?

A9: We'll send professional installation engineer to help you install the equipment, as well as training your workers freely.