Полностью автоматическая машина для розлива чистой воды 3-5

- Категория: Filling Machines >>>

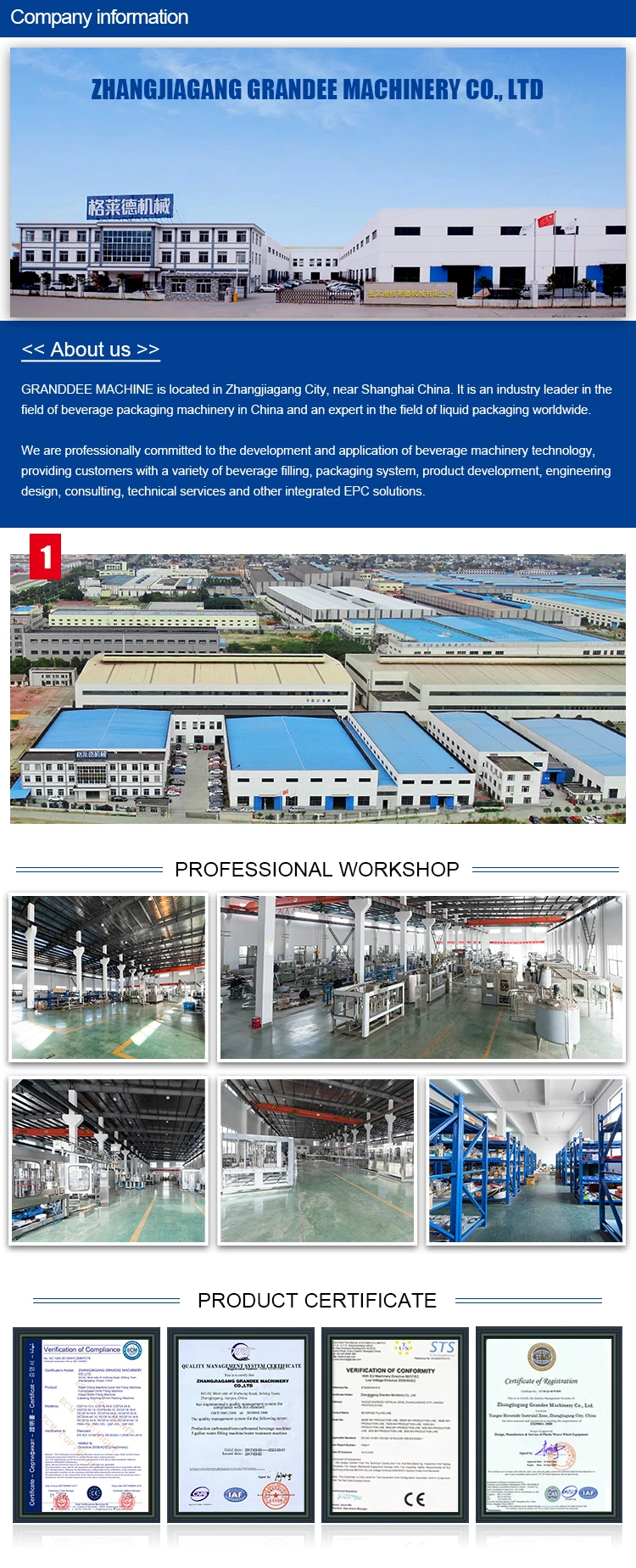

- Поставщик: Zhangjiagang,Grandee,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 2380.86 $* | 2499.1 $* |

| Aug-17-2025 | 2360.49 $* | 2478.79 $* |

| Jul-17-2025 | 1980.42 $* | 2079.66 $* |

| Jun-17-2025 | 2320.99 $* | 2436.98 $* |

| May-17-2025 | 2020.14 $* | 2121.44 $* |

| Apr-17-2025 | 2280.92 $* | 2394.45 $* |

| Mar-17-2025 | 2260.69 $* | 2373.16 $* |

| Feb-17-2025 | 2240.61 $* | 2352.59 $* |

| Jan-17-2025 | 2220.26 $* | 2331.43 $* |

Характеристики

Brief introduction of 5 gallon water production line:

1) This 5 gallon water production line specially produces 3&5 gallons barreled drinking water.

(2)This series barreled filling production line integrates bottle washer, filler and sealer into one unit.

(3) In order to achieve the purpose of washing and sterilizing, bottle washer adopts multiple liquid injections washing and disinfectant spray, and washing solution can be used circularly. The sealer can seal bottle caps automatically.

(4) This filling line equips with water spraying device to sterilize caps of bottles in order to ensure those caps are aseptic and healthy.

(5) This 5 gallon bottling line also can automatically carry out bottle washing, sterilizing, filling, capping, counting and products discharging.

(6) It has features of complete functional, easy operation, and high degree of automation. It is a new kind of 5 gallon barreled water auto-producing line, which integrates mechanism, electricity and pneumatics technologies together.

120BPH Bottle loading by manual :

150BPH 5 gallon bottle feeding in system automatically

QGF-100 5 Gallon / 20liter water filling line with washing system | |||

No. | Machine name | Model | Size(mm) |

1 | Semi Automatic decapper and bottle washing machine | BG-1 | 850x650x1800 |

2 | Main washing filling capping machine | QGF-100 | 3200×1000×1700 |

3 | Light checker | DJ-1 | 1000×150×450 |

4 | Shrinking machine |

| 900x700x1200 |

5 | Feeding in conveyor belt | Plastic chain |

|

6 | Full bottles outlet conveyor | SUS304 |

|

7 | Roller conveyor | SUS304 | 1500x600 |

8 | Laser / ink jet printer | 20W | 340*220*100 |

Electrical component information | ||

No | Name | Brand |

1 | Touch screen / HTM | Siemens / Mitsubishi |

2 | PLC | Siemens / Mitsubishi |

3 | Switch, Button | Schneider |

4 | Air cylinder | AIRTAC |

5 | Water pump | CNP |

6 | Sensor / Approaching switch | AUTONICS |

| Semi automatic 5 gallon decapper and washing machine (associated equipment for this filling line) 1.The empty barrel inverted and insertion pulling out cap stations, foot air valve plate, pulling cap head will pull off the lid into the pipeline. 2.Open the brush barrel cover, insert empty barrel pulled out cap into washing barrel station, close machine cover and automatically open water pumps and hair brush. |

Washing Process

1.In order to achieve the purpose of washing and sterilizing, bottle washer adopts multiple liquid injections washing and disinfectant spray, and washing solution can be used circularly. 2.There are five or seven flushing process: First, second steps are disinfectant, the third step: drip dry, four step: recycling water inside and outside rinsing, five step: pure water and drip dry. |  |

| Filling and capping machine This filling machine working with automatic cap holding and cap hopper, use gravity filling type. full bottle filling process. One head capping machine |

Automatic barrel loader:

The empty barrel cleaned by inside and outside brushing machine sending through automatic loading system by transmission chain, loading barrel counter counting 1pcs barrel, blocking barrel cylinder action to stop feeding barrel, loading and pushing barrel action, and pushing barrel to barrel inverting frame reset. |  |

| Light checker and steam heating shrink machine:

Inspection light is used for lighting when inspect whether exist sundries in barrel. Heat shrinking machine is consist of water vessel and electric heat up, electric heat up to produce steam.

|

Bottle conveyor system

Including: Automatic empty bottle feeding in system, plastic chain material with driven motor. Full barrel conveyor system with SUS34 material chain |  |

| Roller conveyor system

Material: SUS304 Length:1.5m |

Q1: How to find suitable 5 gallon water filling machine or complete 5 gallon water production line?

A1: Looking for beverage filling machine in www.grandeemachine.en.alibaba.com

Q2: How to start a water factory business ? What's my budget?

A2: First confirm the source water, send the water samples to your local department and get the water analysis report, then tell us how many tons or liters per your you want to make, like 2000liters/hr, 4000liters/hr, 6000liters/hr, etc, then we can know to choose which model for you, like QGF-80, QGF-120, QGF-150, QGF-300, QGF450, QGF-600,etc.

Q3: How to confirm the bottle shapes that is very attractive for your customer ?

A3: Our engineer can design 5 gallon bottle shapes with your company Logo for you.

Q4: Which kinds of machines included in one complete 5 gallon water production line?

A4: Semi auto or Automatic Decapping machine, internal and external brush washing machine, main 5 gallon washing filling capping machine, automatic labeling machine (optional) light checker, shrink tunnel, feeding bottle conveyors, bottle out conveyors.

Q5: Are you a trading company or a manufactory?

A5: We are the manufacture of water/beverage filling machine and water treatment system over 10 years.We just not only sell drinking water machines and other related equipment , Quality is our culture. We have rich experienced engineers with technicians working team , providing good and after-sales service term , professional salesman terms .

Q6: Do you have technical support after we purchased your machines?

A6: We will arrange our professional technical to go aboard to your factory, they will help you and teach you how to install and maintenance the machines which you purchased. Or help you to fix machine when it has problems.

Q7: If you buy our machines, can you offer us wear-out spare pats?

A7: We provide our high quality machine 2 years guarantee , and we will also offer you 2 years wear-out spare parts for free. Once your machines broken or doesn't work within 2 years and you can't solve it, firstly, we will try to help you to find problems from your words description by phone or other communication tolls. Secondly, if the phone solutions still not work, our engineers will go to your factory to solve it. Meanwhile, they will teach you the related experiences for fixing.