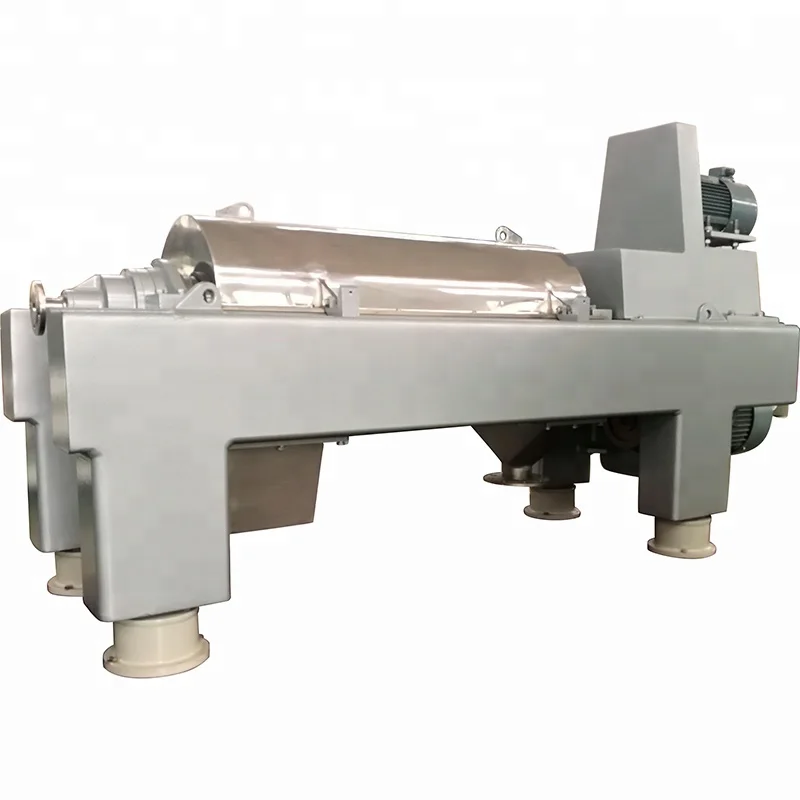

Сепарационная центрифуга для обработки рыбьего

- Категория: Приспособление для разделения >>>

- Поставщик: Juneng,Machinery,(China),Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.61 $* | 0.34 $* |

| Aug-16-2025 | 0.83 $* | 0.94 $* |

| Jul-16-2025 | 0.78 $* | 0.14 $* |

| Jun-16-2025 | 0.82 $* | 0.48 $* |

| May-16-2025 | 0.90 $* | 0.34 $* |

| Apr-16-2025 | 0.63 $* | 0.32 $* |

| Mar-16-2025 | 0.37 $* | 0.47 $* |

| Feb-16-2025 | 0.59 $* | 0.53 $* |

| Jan-16-2025 | 0.35 $* | 0.53 $* |

Характеристики

Product Application

Decanter centrifuge is a mechanical equipment which utilize the principle of centrifugal and sedimentation and can carry out continual separate the suspend liquid with density difference.

The centrifuges which made by out factory can clarify, dehydrate and classify the suspensions with 0.002-3 mm solid-phase particles and thickness range at 0.5~40%. The product can be classify into two type LW-counter-current and parallel-current base on its structure feature.

According to feed feature, product can be divide into LW two-phase separator, LWS three-phase separator. It is suitable for separating different feed under different process condition, and widely use in pharmaceutical, food, chemical, light industry, environmental protection industry etc.

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

| \t | \t | \t | \t | \t | \t |

*** F: Ex-proof, W:Waste water, S: Three phase FS: Ex-- proof and three phase

Main Features

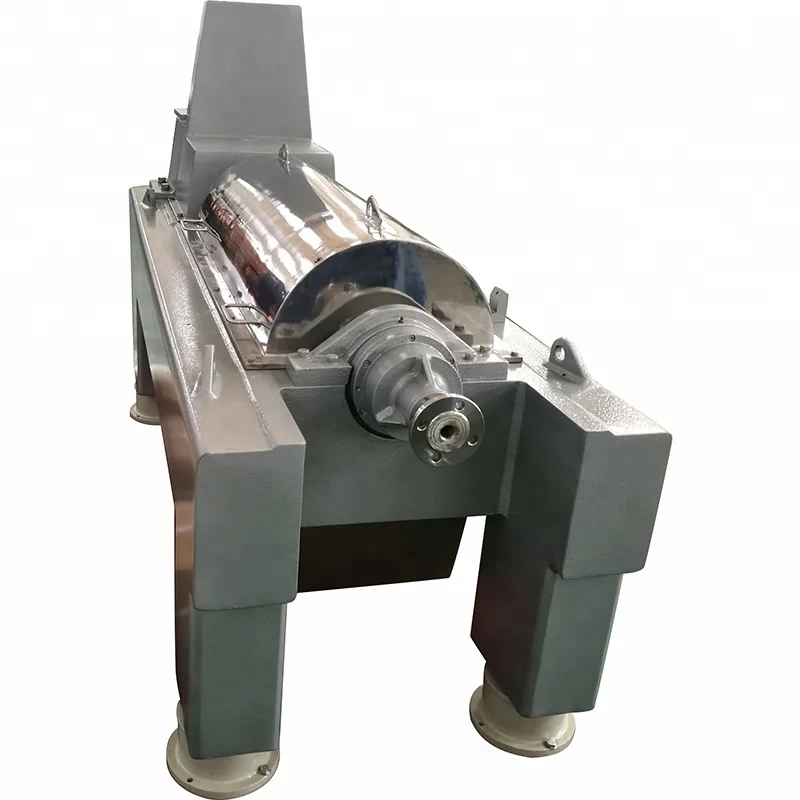

•\tAll parts coming into contact with the product are made of stainless steel.

•\t3-phase AC motor for controlled torque starting via frequency converter

•\tApproximately 80 to 90 % of the oil is recovered.

•\tLow personnel costs due to continuous and automatic operation.

•\tHighest g-force for higher solids output

•\tAdjustable bowl speed via VFD

•\tAutomatic adjustment of differential speed via VFD

•\tTwo motor drive

•\tBelts for both primary motor and secondary motor

Advantages.

1. Lower cake transportation costs due to very dry solids

2. Better recovery of nutrients due to very high separation efficiency

3. Lower fresh water consumption compared to other processes

4. Continuous and fully automatic operation

5. 24 h operating reliability

6. Optimum wear protection

7. Energy saving design

8. Easy to operate

9. Easy to maintain

10. Simple assembly/dismantling

Application

1.\tWashing and dehydration of starch

2.Dehydration of soybean wheat proteins

3.Dehydration of fish meal and fish

4.Dehydration of brewers’ grains

5.Purification of juice and dehydration of fruit fiber

6.Separation and purification of animal and vegetable oil

7.Separation and purification of coal tar

8.Clarification and purification of gypsum

9.Classification and dehydration of starch

10.Classification and dehydration of Kaolin and graphic

11.Classification and dehydration of dyes and pigments

12.Classification and dehydration of mineral thick liquid

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

| \t | \t |

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

*Maintaince and repair

| \t | |

| \t | \t |

| \t | \t |

| \t | \t |

Pusher centrifuge

91.8% Response Rate

Mixing pump

91.8% Response Rate

solid liquid filter

91.8% Response Rate