MSFM-H1080 автоматическая машина для ламинирования магнитного

- Категория: Ламинаторы >>>

- Поставщик: Ruian,Mosun,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 101150.83 $* | 106208.16 $* |

| Aug-20-2025 | 100300.38 $* | 105315.96 $* |

| Jul-20-2025 | 84150.94 $* | 88358.19 $* |

| Jun-20-2025 | 98600.80 $* | 103530.36 $* |

| May-20-2025 | 85850.69 $* | 90143.16 $* |

| Apr-20-2025 | 96900.67 $* | 101745.46 $* |

| Mar-20-2025 | 96050.17 $* | 100853.78 $* |

| Feb-20-2025 | 95200.91 $* | 99960.24 $* |

| Jan-20-2025 | 94350.38 $* | 99068.61 $* |

Характеристики

Product Appearance

Application

Products Description

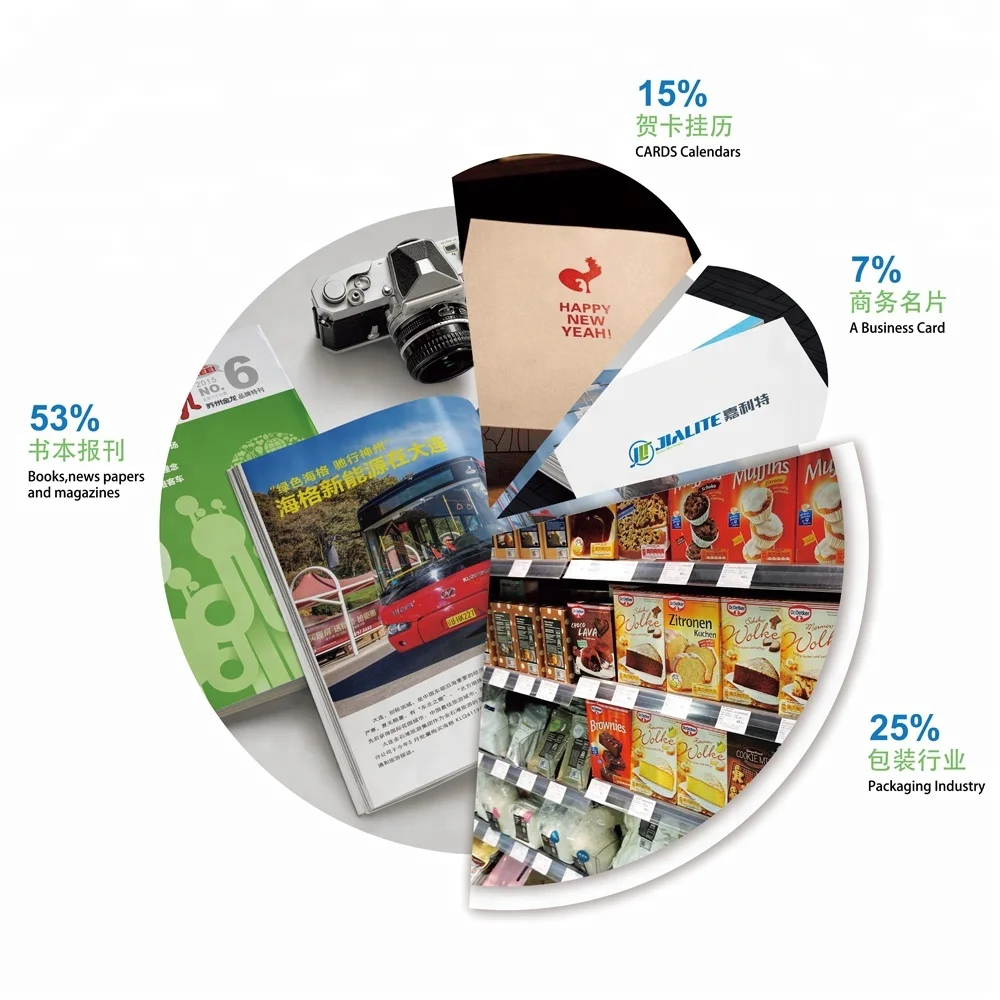

FM-H fully Automatic Vertical High-precision and multi-duty laminator as a professional equipment used for plastic film laminating on the surface of paper printed matter. Widely applicable for laminating in packaging, paper box, books, magazines, calendars, and commercial cards fields, Improving the printing matter grades, and achieve the purpose of dustproof, waterproof, oil proof. it’s the best choice for printing and laminating enterprises of all scales.

Specifications for NFM-H1080 Automatic Water Based Glue PET Large Size Screen Film Laminating Machine for A2 Size

Model | NFM-H |

Max Paper Sheet Size | 1080*1100mm |

Min Paper Sheet Size | 360*290mm |

Speed | 10-90m/min |

Paper Thickness | 80-500gsm |

Overlap Precision | ≤±2 |

Film Thickness | 4-10g/m2 |

Pre-gluing Film Thickness | 1005,1006,1206 (1508 and 1208 for deep embossing paper) |

Non-stop Feeding Height | 1150mm |

Collector Paper Height (incl. pallet) | 1050mm |

Main Motor Power | 5kw |

Whole Machine Power | 60kw |

Working Power | 35-45kw |

Voltage | 380V 50Hz 3P |

Cable Thickness | 25mm2 |

Weight | 9800kgs |

Dimension | 8400*2630*3000mm |

Loading | 40HQ |

Details Images

FEEDING UNIT:

1.Servo Motor Feeder, 4 suckers for lifting and 4 suckers for conveying structure. Max Speed 12000 sheets/h

2.The paper feeding table has upper and lower over-limit protection

3.The height of non-stop feeding can reach 1150mm, pre-stacking device, non-stop feeding

4.Intelligent adjustment of front and rear positions of Feeder, just input product data on the control panel

5.BECKER VACUUM PUMP

2.The paper feeding table has upper and lower over-limit protection

3.The height of non-stop feeding can reach 1150mm, pre-stacking device, non-stop feeding

4.Intelligent adjustment of front and rear positions of Feeder, just input product data on the control panel

5.BECKER VACUUM PUMP

CONVEYING TABLE AND OVERLAP:

1.The conveying table adopts customized stainless steel corrugated board

2.The brush wheel and rubber pressing wheel move smoothly

3.Servo motor overlap, improve accuracy of lap, error≤±2mm

2.The brush wheel and rubber pressing wheel move smoothly

3.Servo motor overlap, improve accuracy of lap, error≤±2mm

LAMINATOR HOST:

1.Glue roller and metering roller are driven by dual independent motors, making adjustment more convenient

2.Drying roller diameter increased to 1000mm, using electromagnetic heating system.

3.The heating press roller adopts a segmented heating system, efficient and energy-saving

4.Max pressure of press roller is 12T

5.Gluing system Teflon process treatment, easy to clean and non-sticky

2.Drying roller diameter increased to 1000mm, using electromagnetic heating system.

3.The heating press roller adopts a segmented heating system, efficient and energy-saving

4.Max pressure of press roller is 12T

5.Gluing system Teflon process treatment, easy to clean and non-sticky

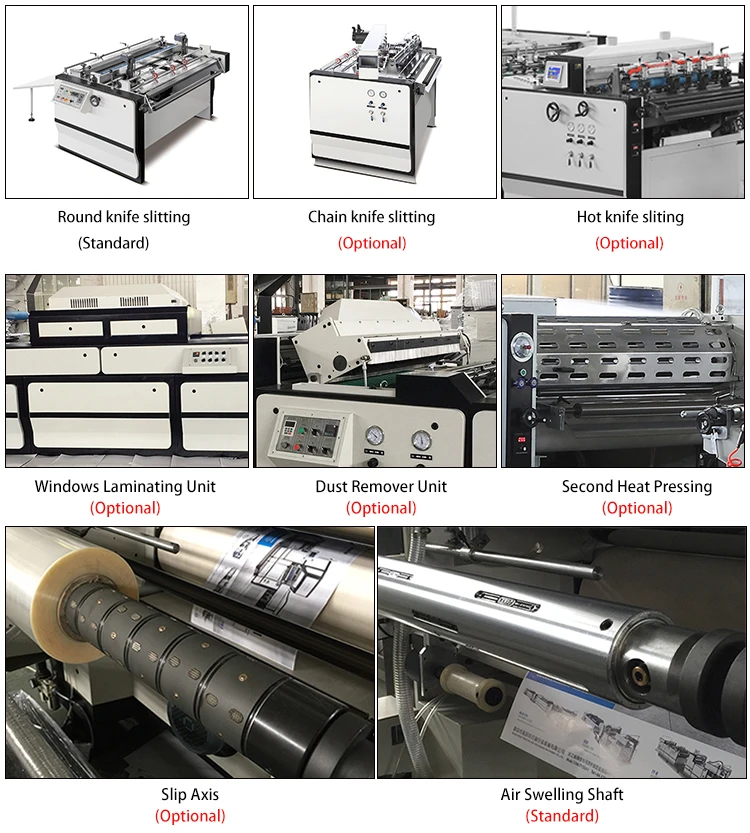

CUTTING UNIT:

1.The paper cutter is equipped with a tension controller and an anti-curl device to ensure that the paper is flat and not curled.

2.The paper cutting part contains grinding wheel, disc knife and chain knife for slitting, meeting customers' requirements for slitting films of different materials

3.The bounce roller is controlled by an independent motor, and the paper can be separated by using the speed difference

4.Hot knife low pressure direct heating and slitting without tail film, detecting paper thickness and slitting, accurate and efficient

2.The paper cutting part contains grinding wheel, disc knife and chain knife for slitting, meeting customers' requirements for slitting films of different materials

3.The bounce roller is controlled by an independent motor, and the paper can be separated by using the speed difference

4.Hot knife low pressure direct heating and slitting without tail film, detecting paper thickness and slitting, accurate and efficient

NON-STOP COLLECTOR:

1.The non-stop collector height can reach 1050mm. When the stack is almost full, the delivery conveyor belt will automatically extend to accept the paper. The collector platform will drop. After the tray is replaced, the platform will recycle and complete the non-stop collector.

2.Adopt pneumatic paper sorting structure to ensure the neatness of the paper and facilitate the next process

3.with a reduction wheel to prevent the paper from being damaged due to too fast hitting the baffle

4.Counting electric eye, the number of running paper is displayed on the display screen at the take-up machine, which can be cleared and accumulated

5.Induction electric eye, sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the take-up machine will overturn and lift the paper

2.Adopt pneumatic paper sorting structure to ensure the neatness of the paper and facilitate the next process

3.with a reduction wheel to prevent the paper from being damaged due to too fast hitting the baffle

4.Counting electric eye, the number of running paper is displayed on the display screen at the take-up machine, which can be cleared and accumulated

5.Induction electric eye, sensing the length of the paper, if the length of the paper changes, the belt will accelerate, and the baffle of the take-up machine will overturn and lift the paper

Product packaging

Company Profile

Company Information

SERVICE AND WARRANTY:

Marketing & Technical Service Center Technical Training Professional operating engineers sent by GREAT is responsible for equipment installation and commissioning work at the same time, training for user operators.

The customer need to bear his Visa, round-trip ticket, whole trip room and board and afford 100.00 USD per day wage.

Training Content:

All machines have been finished all adjustment and test in GREAT workshop before delivery, the mechanical structure, components adjustment, electrical operation of the switch, and the matters needing attention, day-to-day maintenance of equipment, etc., In order to ensure the normal operation of equipment, later.

Warranty:

13 months for electric parts, the service is for whole life, once you asked the spare parts, we can send immediately, customer afford the courier fee. (Since the date of purchase from delivery and on the board, within 13 months)

The customer need to bear his Visa, round-trip ticket, whole trip room and board and afford 100.00 USD per day wage.

Training Content:

All machines have been finished all adjustment and test in GREAT workshop before delivery, the mechanical structure, components adjustment, electrical operation of the switch, and the matters needing attention, day-to-day maintenance of equipment, etc., In order to ensure the normal operation of equipment, later.

Warranty:

13 months for electric parts, the service is for whole life, once you asked the spare parts, we can send immediately, customer afford the courier fee. (Since the date of purchase from delivery and on the board, within 13 months)

Certifications

Похожие товары

Машина для ламинирования мягкой пленки с жидким клеем

US $11000-$12000

Высокоскоростная машина для ламинирования рулонов без растворителей

US $80000-$120000

Деревообрабатывающая машина для ламинирования ПВХ пленки МДФ

US $8300-$52000