Порошок крахмала ротационный двойной роликовый барабан сушилка для скрапки специальное сушильное

- Категория: Сушильное оборудование >>>

- Поставщик: Zhengzhou,Great,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 287037.6 $* | 292778.64 $* |

| Jul-19-2025 | 232793.76 $* | 237449.68 $* |

| Jun-19-2025 | 282516.35 $* | 288166.24 $* |

| May-19-2025 | 280256.46 $* | 285861.73 $* |

| Apr-19-2025 | 223753.60 $* | 228228.46 $* |

| Mar-19-2025 | 275736.74 $* | 281251.0 $* |

| Feb-19-2025 | 273476.76 $* | 278946.71 $* |

| Jan-19-2025 | 271216.42 $* | 276640.81 $* |

Характеристики

Scrape dryer

1.Description of Scraper Dryer

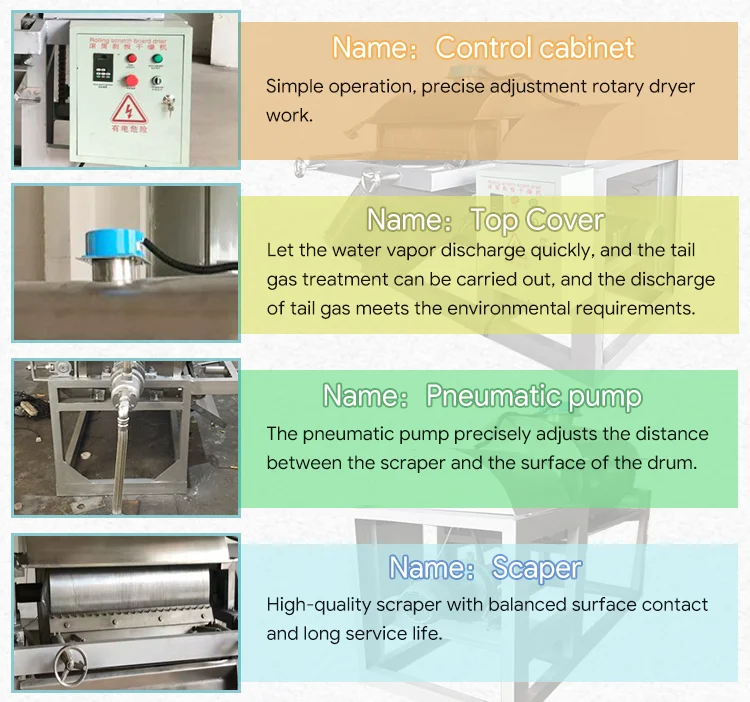

Scrape dryer is a kind of rotating continuous drying equipment with internal heating conducting-style. Certain thickness of materials film attach to the drum from material liquid vessel under the drum.Heat is transferred to the internal wall of the cylinder through pipes and then to the external wall and to materials film,to evaporate the moisture in materials film so as to dry materials.Dried products are then scraped off by the blade fitted on the surface of the cylinder, fall down to the spiral conveyor under the blade,and are conveyed,collected and packed.

2.Applications of Scraper Dryer

It is suitable for drying liquid raw material or sticky material in chemical industry,dyestuff industry, pharmaceutical industry,foodstuff industry,and metallurgy industry and so on.

Click Now for Catalogs & Factory Price!

Technical parameters:

| Item Model | Cylider Size | Effective Heating Area (m²) |

Drying cacity kg.water/m².h |

Steam Consumption kg/h |

Power (kw) |

Dimension (mm) |

Weight (kg) |

| GRT-600 | 600*800 | 1.12 | 40-70 | 100-175 | 2.2 | 1700*800*1500 | 850 |

| GRT-700 | 700*1000 | 1.65 | 60-90 | 150-225 | 3 | 2100*1000*1800 | 1210 |

| GRT-800 | 800*1200 | 2.26 | 90-130 | 225-325 | 4 | 2500*1100*1980 | 1700 |

| GRT-1000 | 1000*1400 | 3.3 | 130-190 | 325-475 | 5.5 | 2700*1300*2250 | 2100 |

| GRT-1200 | 1200*1500 | 4.24 | 160-250 | 400-625 | 7.5 | 2800*1500*2450 | 2650 |

| GRT-1400 | 1400*1600 | 5.28 | 210-310 | 525-775 | 11 | 3150*1700*2800 | 3200 |

| GRT-1600 | 1600*1800 | 6.79 | 270-400 | 675-1000 | 11 | 3350*1900*3150 | 4350 |

| GRT-1800 | 1800*2000 | 8.48 | 330-500 | 800-1200 | 15 | 3600*2050*3500 | 5100 |

| GRT-1800A | 1800*2500 | 10.6 | 420-630 | 1050-1575 | 18.5 | 4100*2050*3500 | 6150 |

3.Features of Scraper Dryer

High thermal efficiency. Because the heat transfer mechanism of the drum dryer is heat conduction, the heat transfer direction is consistent throughout the rest of the operation cycle. Except for the cover heat dissipation and heat radiation loss, the heat is all used for the evaporation of the wet film of the film, and the thermal efficiency can reach 80%~90%.

The operation is flexible and wide in applicability. Many drying factors can be adjusted for the drum dryer. For example, the concentration of the feed, the thickness of the coating film, the temperature of the heating medium, the rotation speed of the drum, etc., can change the drying efficiency of the drum dryer, and many factors are not involved. This brings great convenience to the drum drying operation, so that it can adapt to the drying of various materials and different production requirements.

Drying time is short. The drying cycle of the material is generally only 10-300 seconds, which is more suitable for heat sensitive materials. If the drum dryer is placed in a vacuum, it can be operated under reduced pressure.

The drying rate is large. Since the coating film is thin on the wall of the cylinder, generally 0.3-1.5mm, and the heat transfer and mass transfer directions are the same, and the surface of the film can maintain the evaporation strength of 100-150kg H2O/m2.h.

Great Machinery Equipment (zheng zhou) Co., Ltd.

2007 sees the company growth and its business scope enlarge from drying machine to a complete production line, such as washing machine,cutting machine, and packaging machine.Company is a integration of high-tec research, production,sales and service with total investment of 5 hundred million located in High-tec development zone in Zheng zhou city. We mainly supply a whole production chain of closely related machines, including, cleaning machine, stripping machine, drying machine packing machine.

1.Are you manufacturer or trader? Where are your factory located?

We are manufacturer and we are located in Henan,China.and we can provide the competitive price and good quality.

2.Can I use my own raw materials for extraction test?

Yes, of course. We can do extraction tests and send videos and test reports for your reference.

3.Do you have OEM service? Do you provide parts?

Yes, we will, as long as you provide us with your drawings and detailed requirements.

spray dryer for Liquid dry powder

hot air circulation drying machine

Похожие товары

Большая сушилка для пищевых продуктов для дома

Инфракрасная газовая горелка HD162 для сушки краски

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com