Автоматическая штамповочная машина для горячего тиснения фольгой LK106MTF с

- Категория: Paper Processing Machinery >>>

- Поставщик: Wenzhou,Guangya,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.15 $* | 0.76 $* |

| Aug-16-2025 | 0.64 $* | 0.0 $* |

| Jul-16-2025 | 0.46 $* | 0.56 $* |

| Jun-16-2025 | 0.16 $* | 0.69 $* |

| May-16-2025 | 0.98 $* | 0.92 $* |

| Apr-16-2025 | 0.30 $* | 0.34 $* |

| Mar-16-2025 | 0.39 $* | 0.60 $* |

| Feb-16-2025 | 0.18 $* | 0.58 $* |

| Jan-16-2025 | 0.83 $* | 0.72 $* |

Характеристики

This Automatic Foil Stamping and Die Cutting Machine with Stripping adopts numerous advanced pneumatic and servo driving processing technology from home and abroad. After the strict assembly quality control, it has the advantage of simple operation and safe reliable.

Mould | LK106MTF |

Max. sheet size | 1060mm*770mm |

Min. sheet size | 450mm*370mm |

Max. die cutting size | 1050mm*750mm |

Zones individually heated | 12 zones (each zones can be adjusted independently, the highest temperature will reach 200℃) |

Max. working speed | 6500s/h |

Max. stripping speed | 6000s/h |

Gripper margin | 8-17mm |

Paper ranger | 90-2000g/㎡(cardboard) 0.1-2mm(cardboard)≤4mm(corrugated) |

Max. cutting force | 300T |

Max .delivery pile height | 1200mm |

Max. feeding pile height | 1350mm |

Main motor power | 15kw |

Power rating | 35.6kw |

Machine weight | 16000kg |

Air requirements | 0.6Mpa,>0.37m³/min |

Overall machine dimensions | 6050*4200*2260 |

Feeder

1. Pile tray with a handle allowing manual lateral correction of the pile during production

2. Feeder protective device in case of crashing

3. Feeder is equipped with 4 lifting suction cups and 4 transport suction cups.

4. The suction cups are adjustable according to the paper deformation in a lateral way

5. Side blowers adjustable with Centerline marks. Blowers on both side of the feed system separate the product for a smooth feeding process

6. Adjustable while in operation: to fine-tune the feeder cycle to the platen

7. Safety system for lowering the pile tray

Feed table

1. Covered with an anti-static stainless steel plate

2. Double sheet detector

3. Support plates at the entry of platen station

4. Sheet hold-down device (guiding the sheets to the front lays)

5. Upper frame with manual lifting device

6. Wide conveyor belts ensure sheets accurately to the front and side lay units

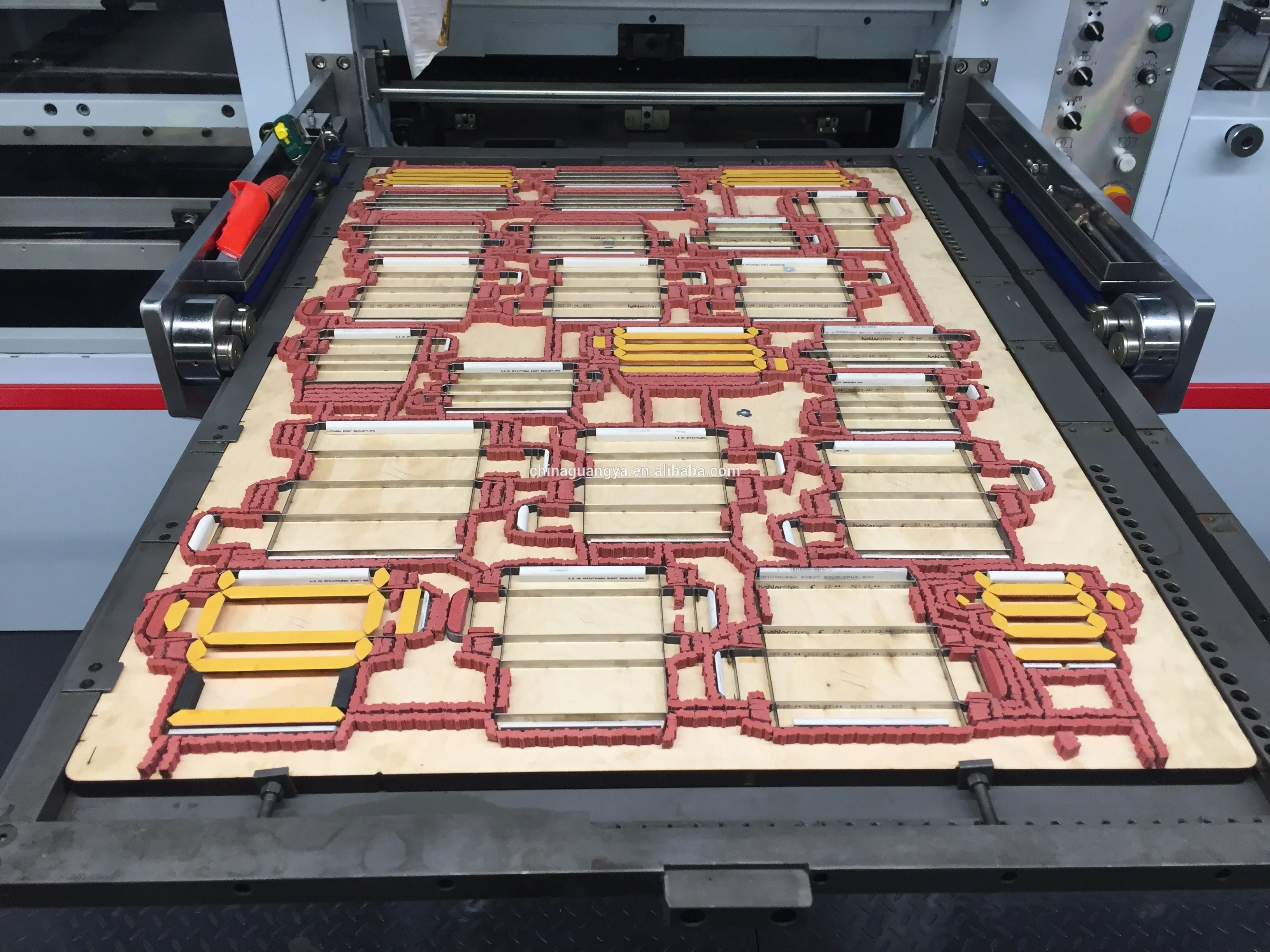

Platen

1. Heated upper head

2. With 12 independent heating zones controlled by PID system

3. Gripper reopening device

4. Gripper fine adjustment

5. Automatic "on and off" pressure device of the platen

6. Equipment centering and locking.

7. Automatic locking of the chase against the upper beam

8. Measurement of the cutting force with strain gauge automatically

Stripping section

1. The stripping frame adopts upper, middle, lower structure

2. The stripping needle and male-female plate are available.

3. The stripping frame is equipped with centralized positioning and quick-clock system

4. The upper stripping frame was controlled by the motor

Delivery

1. Pile tray

2. Pneumatically controlled pivoting front joggers

3. Adjustable rear and side joggers with centerline marks

4. Braking Brush

5. Manual non-stop rack

Pre-Sales Service

* Testing support in our factory

* Inspect machine in our Factory

After-Sales Service

* Training how to install the machine, training how to use the machine

* Engineers available to service machinery overseas