Установка для дистилляции отработанных шин и пластикового пиролиза без

- Категория: Machine Oil Purifier >>>

- Поставщик: Xinxiang,Huayin,Renewable,Energy,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 61880.90 $* | 64974.94 $* |

| Aug-17-2025 | 61360.15 $* | 64428.45 $* |

| Jul-17-2025 | 51480.79 $* | 54054.19 $* |

| Jun-17-2025 | 60320.71 $* | 63336.68 $* |

| May-17-2025 | 52520.49 $* | 55146.63 $* |

| Apr-17-2025 | 59280.2 $* | 62244.88 $* |

| Mar-17-2025 | 58760.20 $* | 61698.6 $* |

| Feb-17-2025 | 58240.83 $* | 61152.70 $* |

| Jan-17-2025 | 57720.91 $* | 60606.26 $* |

Характеристики

We are specialized in manufacturing waste tire/plastic/rubber recycling machine, pyrolysis machine and oil distillation machine, oil refining machines, tire oil/plastic oil/engine oil/ship oil refining plants.

We have three workshops producing every parts, professional laboratory improving technology and demo plant which could show customers running machine. And experienced engineers guarantee installation of our equipments and good after -sale service as our company starts from 1993..

We have three factories totally.One is demo factory for showing our running machine lines to customers;

Another is our big workshop to make the reactors;And the last one is our oldest factory which makes the auxiliary parts .And we also have our own independent laboratory.

We have first class lab. All customer can send us material and we can test the oil yield rate for free

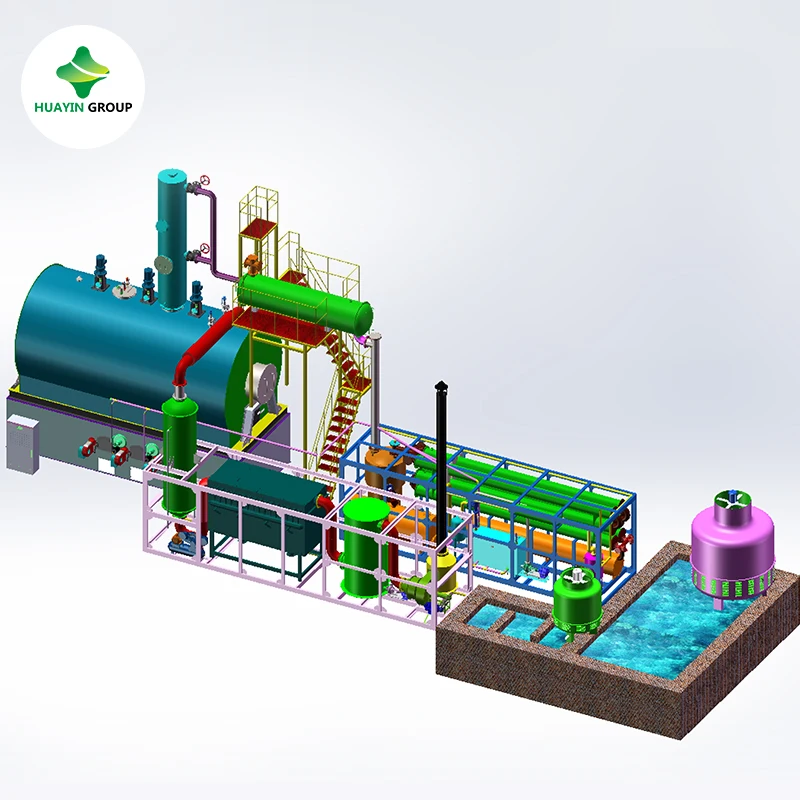

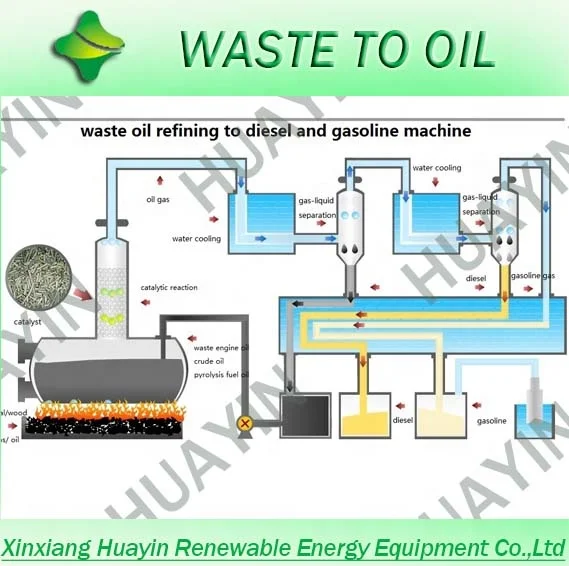

Flow chart

automatically pump waste oil to the reactor - start heating- about 200 degree Celsius gasoline coming out- about 300 diesel coming out - exhaust gas and water.

Output diesel oil pictures

Cases

our machines have been sent to the following countries:Every year we sell about 300 sets machines to this world.

Huayin plants have been exported to over 65 countries including Romania , Itaian , Chile , Poland , hungary , USA, England , Iran, Thailand, Greece, Mexico , Benin , Indonesia ,Dubai , India , Singapore, Philippines , South Korea ,etc.

Main features

Safety.We treat safety as the first important thing in production.

1) Two devices to avoid backfire in production: oil-water separator and anti-back fire device.

2) Vacuum device makes reactor working under ordinary pressure or negative pressure.

3) Temperature monitoring device to avoid excessive working temperature.

4) Pressure gage to monitor the pressure. If it goes above a certain level, the bell will alarm and the safety valve will release the pressure automatically.

5) Carbon black is discharged in a closed situation to avoid catching fire.

Environmental protection

1) The flue gas (caused by burning fuel to heat the reactor) will be purified and cooled by dust removal device, then can be released into air through chimney.

2) The procedure to remove carbon black is working under closed situation to avoid pollution.

3)AlI the water is recycled water, it will notbe discharged.

4)Noise meets industry standards

Energy saving

1) The flame path is designed as spiral so that the quantity of heat can be fully used.

2) The residual gas from pyrolysis is recycled to furnace burning to heating the reactor.

3) The insulation cover is formed by 3 levels: steel plate, rock wool and refractory cement. Excellent thermal insulation effect helps saving fuel.

Long service life

1) The material of reactor is Q345R boiler plate with 16/18mm thickness which is produced by Chinese well-known enterprise. The head of reactor and accessories are using one-piece molding shell cover rather than welded plate.

2) All cutting, rolling and welding works are finished by automatic machines.

3) We know quite well about the material quality and manufacturing process, that’s why we are confident in the service life of our products.

4) We also supply installation service, training service and one year warranty.

Pre-Sales Service

1.24 hours online .Your inquiry will be quick reply by email .

2. Sample testing support.

3. View our Factory.

4. Professionally and patiently introduction,details pictures and working video to show machine

After-Sales Service

1 year warranty, engineers available to service at any time

2. Periodical call visit, to make sure there is no problems of the equipment

3. Design specific maintenance program according to different situation of your plant

Packing and shipping

Our 10 tons tire and plastic pyrolysis reactor is about 9200m *33400mm*31700mm. It is doable to take 40FR.

It is over width and over height.

And Our integrity cooling device is designed to meet 40HQ size and it is easy to ship and move the site place.

FAQ

Q1 : IS that possible to be your agent or distributer ?

Yes , of course , we are glad to work with you to develop the market.

Feel free to contact with us to get more information .

We are the OEM manufacturer for pyrolysis and distillation machine , we are developing partners to occupy our market.

Q2. How to ensure the delivery time ?

We have modern high automation production lines , usually it is just take 5 days to finish producing one set machine.

Moreover , we have prepared machines in our workshop , urgent orders can be negotiated .

Q3. What is your payment terms ?

The Payment terms can be EXW , FOB , CIF , CFR , L/C terms etc.

Other terms can be negotiated.

Q4. Do you provide oil samples ? What is the delivery time ?

Yes , OIl samples can be provided . The delivery time shall be 5 working days.

Q5. Do you produce portable size machine ?

Yes , the smallest capacity is 10kg portable size , we can produce it according to customer requirement.

Need more information, please contact me freely

Any time for you