Черная Нефтеперерабатывающая Установка бренда

- Категория: Machine Oil Purifier >>>

- Поставщик: Chongqing,Lushun,Scientific,&,Technological,Development,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.54 $* | 0.89 $* |

| Aug-17-2025 | 0.8 $* | 0.71 $* |

| Jul-17-2025 | 0.38 $* | 0.72 $* |

| Jun-17-2025 | 0.0 $* | 0.43 $* |

| May-17-2025 | 0.59 $* | 0.54 $* |

| Apr-17-2025 | 0.81 $* | 0.90 $* |

| Mar-17-2025 | 0.51 $* | 0.26 $* |

| Feb-17-2025 | 0.22 $* | 0.31 $* |

| Jan-17-2025 | 0.46 $* | 0.33 $* |

Характеристики

LUSHUN Brand Waste Oil Distillation To Base Oil Plant For Refinery

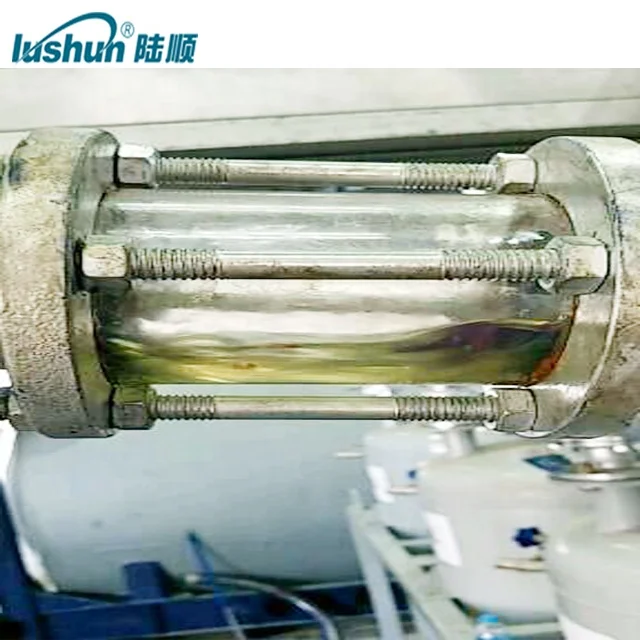

FZB-J Series Waste Distillation Plants are mainly used for recycling lubricating oil such as engine oil, lubrication oil, hydraulic oil, gear oil, diesel, and other oil mixture by vacuum distillation to acquire the qualified base oil and bits of gasoline or diesel. During the process of distillation, the hydrocarbon chain breaks to reform new the molecule of the oil, then turns into oil mist. Then the oil mist turns into liquid by condensation and the qualified oil comes out finally. This plant can effectively remove wearing debris, pitches, waxes, impurities, water contents, carbon deposits, oxides from the oil and decrease its acid value.

FZB-J Series Waste Distillation Plants are especially suitable for oil refineries and small enterprises who is in need of waste oil disposal. It is energy saving, environment friendly, and bits of waste residue generating. The waste residue does not contain oil and pollutes environment. During the processing of the oil regeneration, oil mists and volatile matters are discharged after being burned and purified. Its heat supply mainly adopts burning oil, natural gas, coal or electric heating.

Item | Unit | FZB-J-1 | FZB-J-2 | FZB-J-3 | FZB-J-4 | FZB-J-5 | FZB-J-10 | FZB-J-20 | FZB-J-30 | |

Treatment Capacity | T/d | 1 | 2 | 3 | 4 | 5 | 10 | 20 | 30 | |

Recovery Rate | % | >85 | ||||||||

Working Pressure | MPa | -0.09Mpa(reduced pressure distillation) | ||||||||

Working Temperature | ℃ | 0-350℃ | ||||||||

Working Noise | dB(A) | ≤75 | ||||||||

Power Supply | V | 380V/50Hz, 3-phase 4-wire (Can be customized.) | ||||||||

Heating Method |

| Fuel oil, natural gas, coal or electric heating. | ||||||||

Total Power | KW | 28 | 40 | 50 | 60 | 60 | 60 | 80 | 100 | |

Net Weight | T | 1~2 | 3~5 | 4~5 | 5~6 | 8~10 | 10~15 | 18~22 | 24~26 | |

Floor Space | M^2 | 20~30 | 25~35 | 50~60 | 60~80 | 80~100 | 100~150 | 150~200 | 200~300 | |

1.Adopt the advanced technology of reduced pressure distillation, does not use sulfuric acid and white earth but just a small quantity of additive material which is low-cost and easy to purchase;

2. Very low operation cost. 1T of waste oil treatment just costs about $30 to produce high qualified base oil. Catalyzer is the low-cost basic material commonly used in chemical engineering and can be found anywhere;

3. Easy to operate and with low operation cost, and can be operated well by just 1-2 person;

4. Available for purifying and regenerating waste oil such as waste machine oil, various engine oil and lubricating oil, etc.

5. Environment friendly. This equipment is completely sealed and never lets harmful gas out. And all colloid and asphaltic carbon oil of the waste oil turns into oil sludge which can be used as pitch and fuel;

6. Recycling efficiency is very high. Its recycling rate reaches 85% and higher, while 80%~85% for base oil, 6%~8% for mixture of diesel and gasoline, and 8%~10% for oil sludge;

7. With tight and high vacuum system to ensure the equipment running at ultimate vacuum degree;

8. Regenerates oil of high quality. The regenerated base oil is without particular smell and color changing;

9. Equipped with tail gas treatment system to ensure the emission standard for environmental protection.

Welcome to visit our website, welcome your inquiry.

Contact Person: Mr. Simba Shen

Email: sale @lushuntec.com

Tell: +86-23-65226016 / 65226026 / 65227191 / +86-18716418134

Fax: +86-23-65226013

Address: No. 88, Jinzhugou, Xinqiao Village, Shapingba District

Web:https: //www.cnlushuntec.com