Машина для формования фоторамки

- Категория: Экструдеры для пластика >>>

- Поставщик: Nantong,Bogda,Machinery,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 35105.85 $* | 36860.10 $* |

| Aug-19-2025 | 34810.36 $* | 36551.13 $* |

| Jul-19-2025 | 29205.41 $* | 30665.0 $* |

| Jun-19-2025 | 34220.46 $* | 35931.6 $* |

| May-19-2025 | 29795.3 $* | 31285.79 $* |

| Apr-19-2025 | 33630.87 $* | 35312.55 $* |

| Mar-19-2025 | 33335.32 $* | 35002.95 $* |

| Feb-19-2025 | 33040.11 $* | 34692.51 $* |

| Jan-19-2025 | 32745.23 $* | 34382.58 $* |

Характеристики

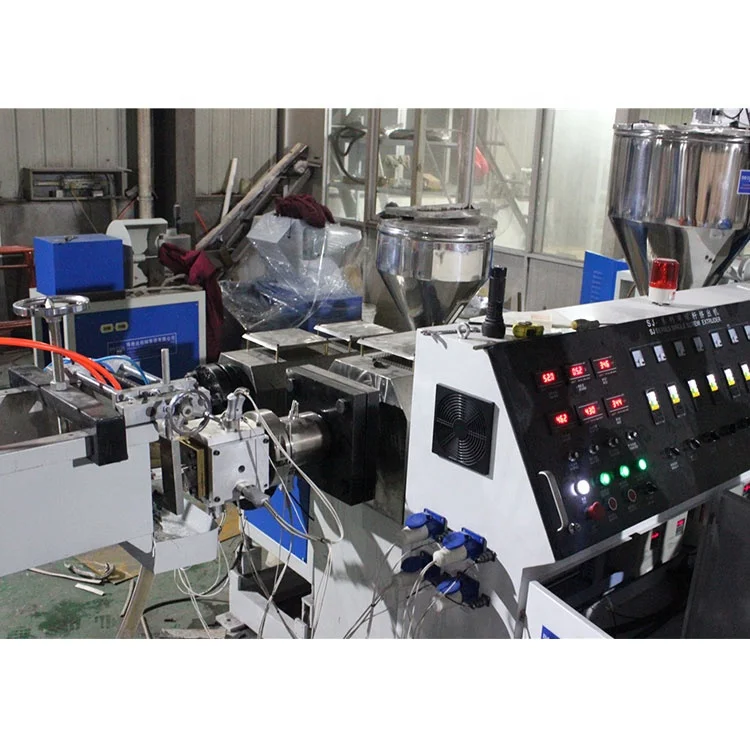

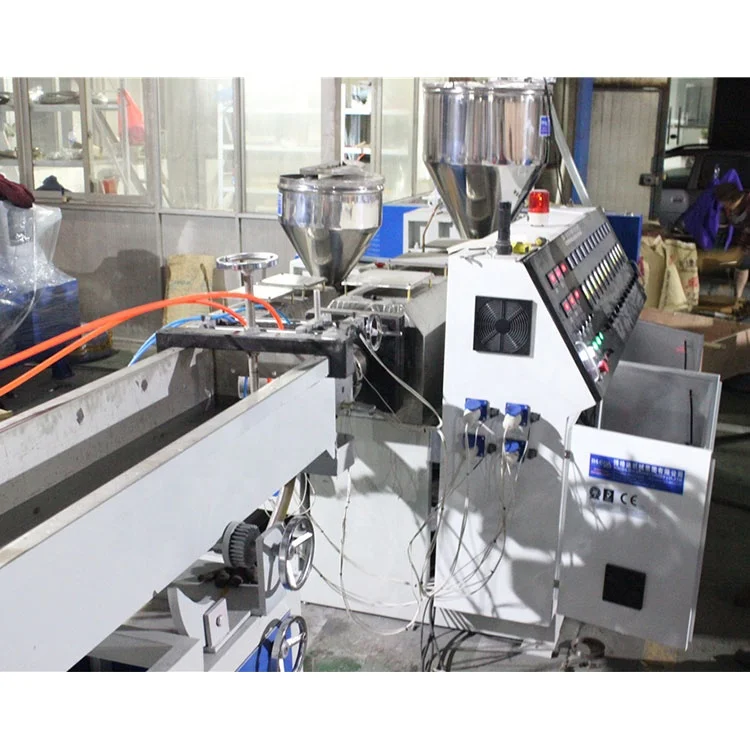

PS picture photo frame moulding making machine

PS picture photo frame moulding making machine can make plastic photo frame profiles which can replace the traditional wooden frame profiles, the costs are much lower and the quality is much better than wooden profiles.

PS picture photo frame moulding making machine: Mixing machine → Material fedding → SJ-Series Single Screw Extruder Machine → Extrusion Mold → Calibration Cooling Tank → Hot-stamp machine → Hau-off machine → Cutter machine → Final Product Stacker.

(Note: Other Auxiliary Machine, such as Crusher, Pulverizer, Mixer, will be provided according to client's requirements)

SJ- Series Singal screw PS picture photo frame moulding making machine .

Screw material: 38CrMoAlA

PS picture photo frame moulding making machine - Siemens Electrical Element

Siemens Brand for Auxiliary Contact Block, Contactor, Thermal Overload Relay

PS picture photo frame moulding making machine aulxiliary machine line.

1. PS picture frame extruder line is a kind of special equipment for extruding PVC compound. With different kinds of molds and auxiliary machines, it can produced all sorts of PVC plastic, profile, plate material, sheet material, bar material and granulation.

2. PS photo frame production line have applied oil cooling system. Barrel is cooled by special wind cooling system.

3. Plastic profile making machine system has applied special computer control. According to customers requirements, most reasonable structure of conical twin screw can be made so as to achieve best plastic city performance and material quality

4. Plastic frame for pictures and photos production Machine is made by high precision special digital screw miller; extruding property can be highly harmonized. It has firstly introduced advanced technique of producing screw with variable pitch and depth, so that the material can be more softly sheared and cut.

5. The distribution box on PS picture fame production line is specially designed, pull force bearing is fully imported, and the drive life span can be prolonged. It can bear large extruding pressure.

6. Plastic Extruder electrical system has mainly applied imported parts, it has multiple alarm system, and there are few problems which can be easily eliminated. The cooling system has applied special design, heat emission area is enlarged, the cooling is rapid, and temperature control tolerance can be ± 1 degree.

| Item | PS picture photo frame moulding making machine |

| Screw diameter | 75mm |

| L/D | 28:1 |

| Screw rotation speed | 1-34.7r/min |

| Output capacity | 60-100KG/H, 600G/M |

| Main motor power | 22kw |

High-speed & Cooling Plastic Mixing machine, please click the following picture to know more about plastic mixer.

- Unique mix raw material: EPS, HIPS, DOP, Foaming, etc.

- Paddle material: Stainless steel casting.

Crusher Machine, please click the following picture to know more about crusher machine.

- Recyle waste PS picture frame for Re-use.

- Blade Material: 9CrSi. Knife Material: u also can choose SKD-11 or D2 as demands.

- Feeding Hopper: Steel Plate (Front and back with sound insulation).

Standard export package - PS picture photo frame moulding making machine

BOGDA Machinery Group is located in Europe and America (Haian) Industrial Park and Shanghai Fengxian (Haian) Industrial Park. It is a high-tech and innovative company dedicated to the research and development and manufacturing of plastic extrusion molding equipment. The company is people-oriented and innovative Development, with its unique corporate culture that has been brewing for many years, and the company’s eager attention to global economic development, it has continued to grow with its majestic momentum and quick response, making itself a large-scale and highly anticipated industry in this industry. Leading technology and excellent quality have been highly recognized by authoritative departments and markets. Products are exported to more than 110 countries and regions such as Europe, America, the Middle East, Southeast Asia, South America, Russia, Turkey, Italy, Poland, Brazil, Romania, etc. Deeply trusted and praised by customers, the company has many subsidiaries such as pipeline equipment, sheet film intelligent equipment, intelligent automation, and granulation equipment. The company has a high-quality talent R&D team and more than 20 years of experience in the industry. A team of mechanical and electrical commissioning engineers, as well as an advanced machining base and a standardized assembly workshop. More than 600 sets of high-end plastic extrusion lines are produced every year.

The main products of the company are:

1. PVC, PP, PE wood plastic production line

2. PVC, PP, SPC wide sheet production line

3. PVC door and window profiles, gusset panels, wall panels, window sill panels, wall hanging panels and other profile production lines

4. PC, PA, ABS and other profile production lines

5. PVC-0 pipe production line 6. HDPE, PVC, PPR, PERT solid wall pipe production line

7. Vertical and horizontal HDPE, PP, PVC corrugated pipe production lines and various reinforced winding pipe production lines

8. PE, PP, PS, PC, ABS, PET, PMMA, GPPS, APET, PETG sheet and sheet production line

9. EVA, POE, PVB, SGP film production line, TPU, TVB film and lithium battery separator production line

10. All kinds of PE, PP, PLA, PET pelletizing units

11. PVC, PE, PP automated centralized feeding system

12. PP meltblown fabric and various spunbond non-woven fabric production lines

13. SPC LVT PVC Floor Production Line

14. Recycling auxiliary equipment related to extrusion line

BOGDA has advanced design concepts in the extrusion field, strives for perfection in product quality, and continues to improve in technology. It can provide customized solutions for each customer to meet the different needs of customers. Project planning, product positioning, plant planning, equipment installation and commissioning, customer staff training, equipment after-sales maintenance and other all-round services. Our advantage is to provide customers with desired, satisfactory, and high-quality products to help customers create the greatest Profits and business opportunities, customer success is our ultimate goal.

1. How many electric, water, air need for the machines?

BOGDA: technical department supply the whole layout for workshop details.

2. Can I operate machine if don’t have experienced engineers?

BOGDA: (1) short-time engineers to customer company (5-15days)

(2) Year-time working as requirements

3. Any quality checking before shipment?

BOGDA: 100% confirm, run and test machines before shipment with quality certificate.

4. How long is the guarantee?

BOGDA: 12 months since the first day customer operates (except wear parts)

5. How can u help us when face some technical problem?

BOGDA: 24 hours by e-mail, message, calling. If problems happens need engineer we will arrange the closest or agent in local country, or send Chinese Engineers to solve in 2 weeks.

6. Where can we get spare part?

BOGDA: we choose International Brand that customer can find it in everywhere, such as Siemens, Schneider, Omron, Delixi etc, or send parts by DHL, Fedex, TNT and other express.