2021 строительное оборудование SINOPOWER! Производственная линия волоконно-цементного картона установка по производству гофрированной

- Категория: Other Construction Material Making Machinery >>>

- Поставщик: Shanghai,Wellink,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 0.11 $* | 0.88 $* |

| Aug-17-2025 | 0.16 $* | 0.81 $* |

| Jul-17-2025 | 0.27 $* | 0.9 $* |

| Jun-17-2025 | 0.34 $* | 0.85 $* |

| May-17-2025 | 0.52 $* | 0.21 $* |

| Apr-17-2025 | 0.38 $* | 0.15 $* |

| Mar-17-2025 | 0.72 $* | 0.6 $* |

| Feb-17-2025 | 0.51 $* | 0.21 $* |

| Jan-17-2025 | 0.13 $* | 0.31 $* |

Характеристики

Scope of Supply

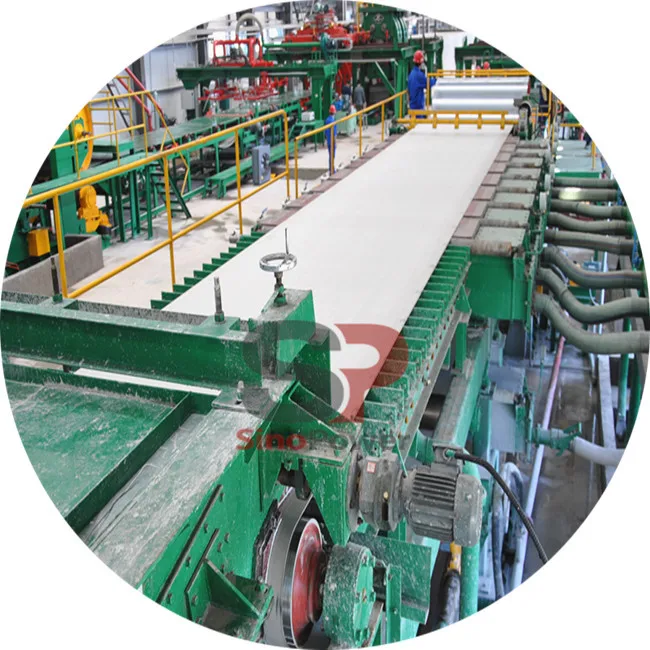

Ø Fiber Cement Board Production Line

Ø Calcium Silicate Board Production line

Ø Asbestos Tile Production Line

Product Application

Fiber Reinforced Calcium Silicate Board is also named Calcium Silicate Board, which is made from Silicon materials, Calcium materials and certain amount of fiber. It is produced after several procedures such as slurry preparation, forming, autoclaving, drying, polishing and after-processing. It has advantages such as light in weight, high in strength, good in processing and easy in decorating, and it can also has performances of heat insulation and fire fighting. So it can be widely used in inner wall and suspended ceiling of buildings, sound panel and partition board partition board of gymnasium, theater and council chamber. It can also be used for special facilities in various industries, such as sound proof wall and apron plate of highway, permanent moulding board of constructional engineering, bay plate of train and ship, movable board for house and outer board of large-scale clad plate factory. Calcium Silicate Board is new environment-protection product with favorable market prospect and economic benefit.

Main Features

1) Product is in accordance with national standard Reinforced Fiber Calcium Silicate Board JC/T564- 2000 of China Material cement, glass fiber, paper pulp, quartz sand,calcium oxide.

2) Density: ≤ 1.5g/cm2 without press > 1.5g/cm2 with press

3) Rupture strength: 15-28 Mpa

4) Thickness: 2-30 mm

5) Panel size: 1220*2440*T(2-30) mm

6) Thermal conductive index: 0.24W/MK(JC/T54)

7) Moisture content: ≤ 10%

8)Water absorption rate:19%

9) Water consumption: 450m3/day

10)Steam construction: 2.0 ton/hour

Machine List | ||||||

1.Sand mortar preparation section | 2.Pulp preparation section | 3.Blending & slurry preparation | 4.Sheet forming, stacking section | |||

5.Pressing section | 6.Pre-curing & template restaking section | 7.Autoclaving & curing section | 8.Board pile split section | |||

9.Drying section | 10.Sanding, edging & tapping section | 11.Air compressor house | 12.Laboratory | |||

13.Heating Equipment | 14.Boiler room | 15.Water supply & drainage equipment | 16.Electric automatization | |||

Fiber cement board is a new type of building decoration material, which is mainly made from high-grade siliceous materials and lime refractory with the mixture of natural fiber as reinforcing material

Suggested using place: widely applied in the suspended ceiling system of business building, entertainment facility, supermarket, hotel, restaurant, hospital, theater, warehouse, apartment building and so on.

Suggested using place: widely applied in the suspended ceiling system of business building, entertainment facility, supermarket, hotel, restaurant, hospital, theater, warehouse, apartment building and so on.

Sheet Making System

Premixer,Round sieve cylinder cage system,Machine head system,Board blanket catcher , Super high pressure water cutting system,4 position stacker system,,Four- position demoulding system,lift platform system,Pump, motor, reducer, bearing and so on.

Press Machine System

There are two kinds of press machine, up lift and down press, up lift is more popular. Press machine is composed of 6 pressing cylinders and 2 lift cylinders, prefill valve is used to control the oil discharge and refule of 6 main cylinders, which is controled by hydraulic station and electric system to ensure the press and lift process of cylinder. Pressure sensor will indicate the press and balance of cylinder, PLC control can be set by multi mode, gear, time and walking distance.

Autoclave And Drying

Board blanket is sent to autoclave to be steamed by winch after demoulding, steaming process include pressure increasing, pressure stablization and pressure release, pressure stablization is most important, which lasts 12-15hous, pressure 0.8-1.1MPa, silica inside board will react with lime and water to form Tobermorite and some hard okenite, hydrated product formed by CaO and SiO2 will consolidate quartz power and reinforcement fiber to get more strength.

After Production Process

Composition:board loader, dryer, sanding machine, polishing machine, squaring and chamfering machine, board palletizing machine, and dust remover.

Boiler

Boiler is kind of equipmetn to produce steam and exchange heat with hot water, the burning of fuel release much heat energy, which is transferred to water by thermal transmission and transform water into steam or hot water. Most factory use coal, natural gas and Gasoline to supply energy to boiler in Casium silicate board industry, steam pressue 16KG.

Electrical Equipment

Ø Composition: PLC, frequency conversion, indicating screen, switch, button, electric control cabinet, wire, cable and so on.

Ø Detailed information see instruction

Tile Production Equipment

Pre-Sales Service

* Inquiry and consulting support.

* View our Factory.

After-Sales Service

* Training how to install the machine, training how to use the machine.

* Engineers available to service machinery overseas.