Полностью автоматическая машина для розлива и укупорки чистой воды производственная линия по цене

- Категория: Разливочные машины >>>

- Поставщик: Zhangjiagang,Sokos,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.15 $* | 0.13 $* |

| Aug-16-2025 | 0.77 $* | 0.2 $* |

| Jul-16-2025 | 0.55 $* | 0.32 $* |

| Jun-16-2025 | 0.48 $* | 0.78 $* |

| May-16-2025 | 0.15 $* | 0.35 $* |

| Apr-16-2025 | 0.3 $* | 0.71 $* |

| Mar-16-2025 | 0.89 $* | 0.76 $* |

| Feb-16-2025 | 0.0 $* | 0.44 $* |

| Jan-16-2025 | 0.3 $* | 0.84 $* |

Характеристики

GOOD QUALITY COMES FROM DETAILS.

We are confident about our product quality because of the Quality Assurance System backed by technical capabilities and productioncapacity. We believe “all steps in production are quality control processes”.

Products Description

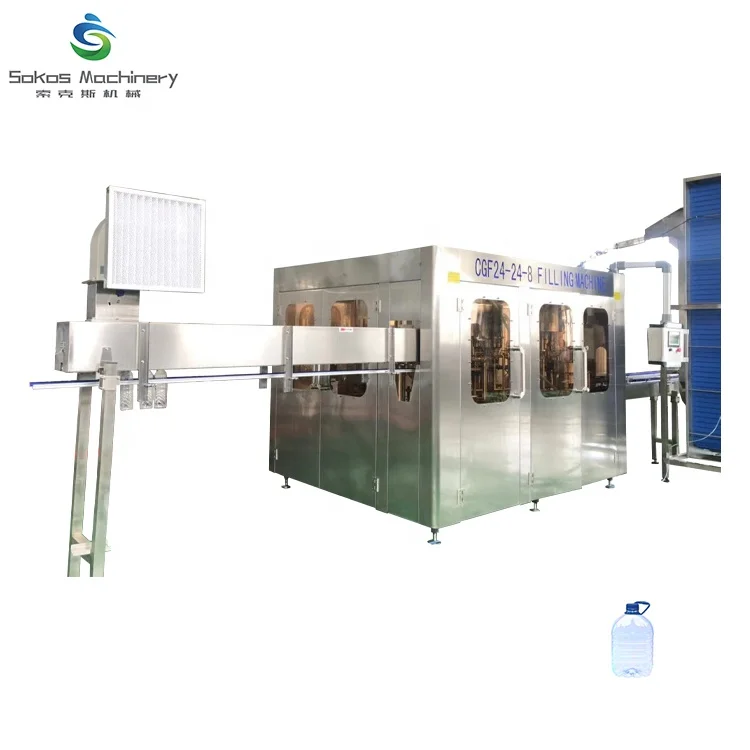

SOKOS Automatic 3-in-1 small bottle water filling line.

This 3-in-1 filling machine is automatic washing,filling and capping.

This washing filling capping machine is mainly used for Non-aerated carbon dioxide drink, such as mineral water, pure water and so on.

The machine design is shorten the time for the drink material contact with outside, Increase the sanitation condition throughout economy benefit.

Details Images

Washing heads-Automatic 3-in-1 small bottle water filling machine

- Into bottle way is air conveyor direct connection with bottle dial.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

- All 304/316 stainless steel rinse heads, water spray style inject design, more save water consumption and more clean.

- 304/316 Stainless steel Gripper with plastic pad, ensure minimal bottle crash during washing.

- 304/316 stainless steel washing pump make the machine more durable.

Filling heads-Automatic 3-in-1 small bottle water filling machine

- 304/316 Stainless steel high precision filling nozzle

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

- Filling volume adjustable in fine rank, same liquid level after filling

- All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean

- 304/316 stainless steel filling pump

- Efficient spray nozzle rinse thoroughly and save water for flushing

Capping heads-Automatic 3-in-1 small bottle water filling machine

- Place and capping system, electromagnetic capping heads, with burden discharge function, make sure minimum bottle crash during

capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

capping

- All 304/316 stainless steel construction

- No bottle no capping

- Automatic stop when lack of bottle

- Capping effect is stable and reliable, Defective rate ≤0.2%

Main Features.

1. Touch screen operation interface.

2. Up and down movement type filling, effectively prevent the foam from being produced, easy to take apart and wash.

3. The filling accuracy can reach ±0.2%.

4. The flling cylinder is ground, unique flling valve design, no leakage.

5. With no bottle no flling and automatic bottle stop function.

6. Design different positioning devices according to the actual situation of the bottle.

7. The equipment is easy to clean, can be disassemble without tools, it can also be cleaned online or high temperature sterilization.

8. PLC programmable control use Japan Mitsubishi.

9. Frequency converter adopts France Schneider.

10. Material contact parts are made of SUS304# stainless steel.

11. The equipment meets the hygiene and safety standards. The user can choose the glass protective cover.

2. Up and down movement type filling, effectively prevent the foam from being produced, easy to take apart and wash.

3. The filling accuracy can reach ±0.2%.

4. The flling cylinder is ground, unique flling valve design, no leakage.

5. With no bottle no flling and automatic bottle stop function.

6. Design different positioning devices according to the actual situation of the bottle.

7. The equipment is easy to clean, can be disassemble without tools, it can also be cleaned online or high temperature sterilization.

8. PLC programmable control use Japan Mitsubishi.

9. Frequency converter adopts France Schneider.

10. Material contact parts are made of SUS304# stainless steel.

11. The equipment meets the hygiene and safety standards. The user can choose the glass protective cover.

Product Paramenters

Model | CGF 8-8-4 | CGF14-12-5 | CGF18-18-6 | CGF24-24-8 | |||

Production capacity | 2000BPH | 3500BPH | 8000BPH | 11000~14000BPH | |||

Bottle height | 330mm | ||||||

Bottle diameter | 50~100mm | ||||||

Bottle volume | 0.2~2L | ||||||

Rinsing pressure | 0.2~0.3Mpa | ||||||

Rinsing water consumption | 0.5T/H | ||||||

Filling precision | ±2~3% | ||||||

Power | 3ph,380V/50Hz,1.5Kw | 3ph,380V/50Hz,1.5Kw | 3ph,380V/50Hz,2.0Kw | 3ph,380V/50Hz,3Kw | |||

Related products

Recommend Products

Why Choose Us

Certificates.

We have been producing our goods with mature technique and first-class quality. Our products are not only marketed inland, but also exported to all over the world, Such as: Africa, Mid East, South Asia, South America. We believe

truthfulness,conscientiousness, enterprising spirit, continuous improvement and creativeness in running business, which helps our finest products enter the market.

truthfulness,conscientiousness, enterprising spirit, continuous improvement and creativeness in running business, which helps our finest products enter the market.

Cooperation Partners.

We have many cooperation partners over the world,such as Mitsubishi,NSK,SIEMENS,SEW,DEMARK,OMRON,FESTO and so on.Product quality assurance is our biggest pursuit.

Our Manufacturer Factory.

At present, we manufacture and provide the following lines to our customers:

Beverage Filling Complete Line -water treatment plants-water filling machine-beverage filling machine-beverage preration system-pckages equipments -coding machine-labeling machine-Pe Film Shrink Wrapping .

Machine -Injection machine -Blow Moulding Machine We welcome distributors and factory owners from around the world to cooperate with us and look forward to receiving your inquiries in the near future.

Exhibition

FAQ

SOKOS MACHINERY - Alibaba Verified Packaging Machinery Supplier - CE ISO

HOW TO FIND SOKOS MACHINERY?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

● Visit exhibition in different countries

● Send SOKOS MACHINERY an request and tell your basic inquiry

● SOKOS MACHINERY sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to SOKOS MACHINERY site

● The meaning of visiting supplier, because seeing is believing, SOKOS MACHINERY with own manufacture and developed& research team,we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE SOKOS MACHINERY HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF SOKOS MACHINERY!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

HOW TO FIND SOKOS MACHINERY?

● Search Alibaba, Made in China, Google, Youtube and find suppliers and manufactrue and not traders

● Visit exhibition in different countries

● Send SOKOS MACHINERY an request and tell your basic inquiry

● SOKOS MACHINERY sales manager will reply you in short time and add instant chatting tool

YOU ARE WELCOME TO OUR FACTORY AT ANY TIME.

● If we can fullfill your request and you interested in our products, you may pay a visit to SOKOS MACHINERY site

● The meaning of visiting supplier, because seeing is believing, SOKOS MACHINERY with own manufacture and developed& research team,we can send you engineers and make sure your after sales service.

HOW TO GUARANTEE YOUR FUNDS TO BE SAFE AND DELIVERY TO BE ON TIME?

● Through Alibaba letter guarantee service, it will ensure the on time delivery and the quality of the equipment you want to buy.

● By letter of credit, you can lock the delivery time easily.

● After the factory visit, You can ensure the facticity of our bank account.

SEE SOKOS MACHINERY HOW TO ENSURE THE QUALITY!

● In order to ensure the accuracy of each part, we are equipped with a variety of professional processing equipment and we have accumulated professional processing methods over the past years.

● Each component before assembly needs strictly control by inspecting personnel.

● Each assembly is in charged by a master who has working experience for more than 5 years

●After all the equipment are completed, we will connect all the machines and run the full production line for at least 12 hours to ensure the stable running in customers' factory

THE AFTER-SALE SERVICE OF SOKOS MACHINERY!

● After finish the production, we will debug the production line, take photos, videos and send them to customers via mail or instant tools

● After the commissioning, we will package the equipment by standard export package for shipment.

● According to the customer's request, we can arrange our engineers to customers' factory to do the installation and training.

● Engineers, sales managers and after-sales service manager will form a after-sales team, online and off line, to follow the customers' project.

For more information,please contact us.