Пластиковый наполнитель цветной маточный экструдер машина для изготовления на

- Категория: Экструдеры для пластика >>>

- Поставщик: Nanjing,Yongjie,Qixin,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-20-2025 | 0.0 $* | 0.4 $* |

| Aug-20-2025 | 0.25 $* | 0.62 $* |

| Jul-20-2025 | 0.49 $* | 0.51 $* |

| Jun-20-2025 | 0.93 $* | 0.42 $* |

| May-20-2025 | 0.98 $* | 0.6 $* |

| Apr-20-2025 | 0.43 $* | 0.40 $* |

| Mar-20-2025 | 0.65 $* | 0.68 $* |

| Feb-20-2025 | 0.34 $* | 0.18 $* |

| Jan-20-2025 | 0.29 $* | 0.10 $* |

Характеристики

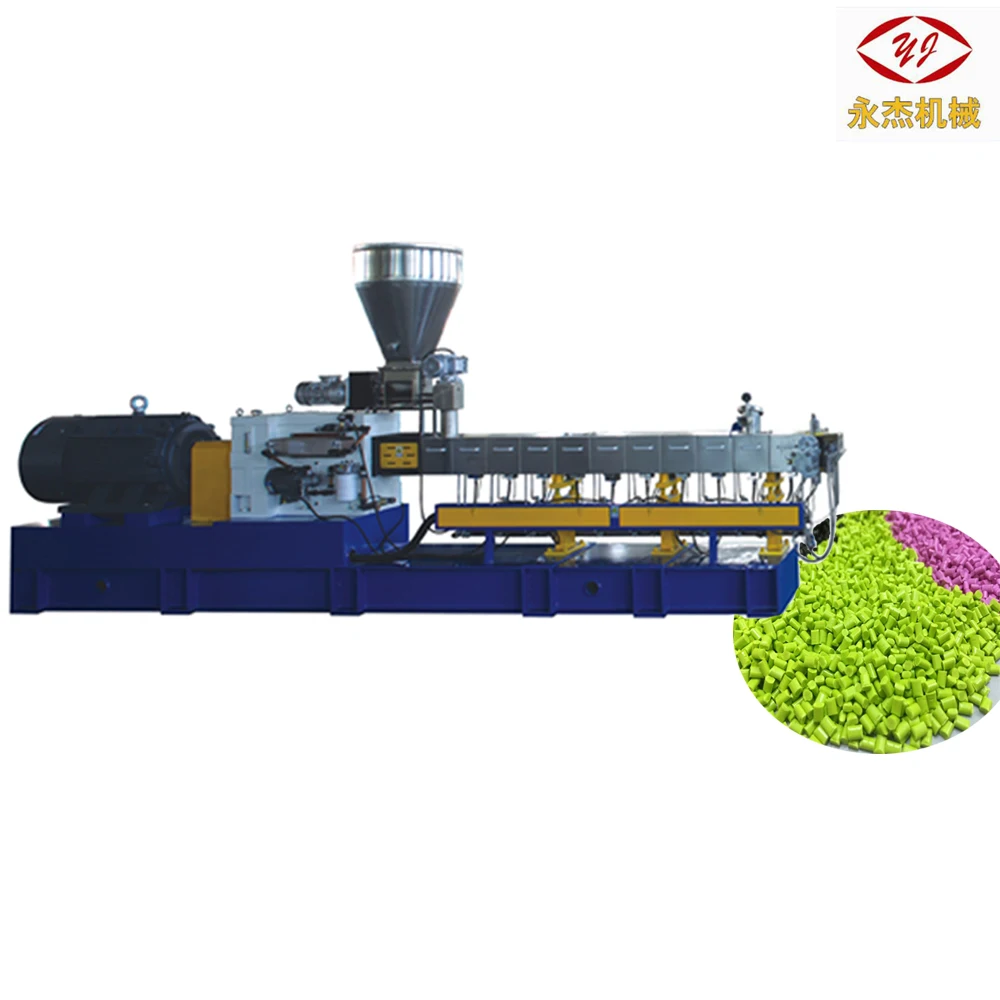

Plastic filler color masterbatch extruder making machine for sale

The company concentrated on research development and manufacturing “high level, accurate, highly sophisticated series product —Co-rotating parallel “cordwood” twin screw extruder. We have provided customer first-class products with strong torque, high production, energy conservation and environmental protection products.

| Model | Diameter(mm) | L/D | RPM ( r/min) | Power (Kw) | Torque(N.m) | T/N | Capacity (Kg/h) |

| SJSL-20 | 20 | 32-44 | 600 | 5.5 | 30 | 4.8 | 6.5-15 |

| SJSL-36 | 36 | 32-48 | 600 | 15 | 115 | 4.2 | 30-75 |

| SJSL-51A | 51 | 32-52 | 500 | 45 | 405 | 5.1 | 100-200 |

| SJSL-51B | 51 | 32-52 | 600 | 55 | 415 | 5.2 | 150-25 |

| SJSL-63A | 63 | 32-62 | 400 | 55 | 620 | 4.4 | 160-250 |

| 500 | 75 | 675 | 4.8 | 200-300 | |||

SJSL-63B | 63 | 32-64 | 600 | 90 | 675 | 4.8 | 225-375 |

| 800 | 110 | 620 | 4.4 | 300-500 | |||

| SJSL-75A | 72 | 32-64 | 400 | 90 | 1015 | 4.7 | 225-350 |

| 500 | 110 | 1005 | 4.6 | 300-550 | |||

| SJSL-75B | 72 | 32-64 | 600 | 132 | 990 | 4.6 | 400-650 |

| 800 | 160 | 900 | 4.2 | 480-800 | |||

| SJSL-92A | 92 | 32-64 | 400 | 250 | 2815 | 5.9 | 650-1050 |

| 500 | 2250 | 4.7 | 750-1250 | ||||

| SJSL-92B | 92 | 32-64 | 600 | 280 | 2365 | 5.0 | 900-1500 |

| 800 | 2250 | 4.7 | 1200-2000 | ||||

| SJSL-135A | 135 | 32-48 | 400 | 315 | 6190 | 4.6 | 1500-2500 |

| SJSL-135B | 135 | 32-48 | 500 | 400 | 6750 | 5.1 | 200-3500 |

Application for water strand pelletizing:

1. Master batch and color master batch:

PP/PE/ABS+Caco3/Sio2(silicon dioxide)/talc(chalk)/carbon black

2. PP/PA/PA6/PA66/PA10/PA1012/ABS/PBT/PET/POM+glass fiber/carbon

Fiber/iron fiber

3. PBT, PET, etc. recycling

4. EVA

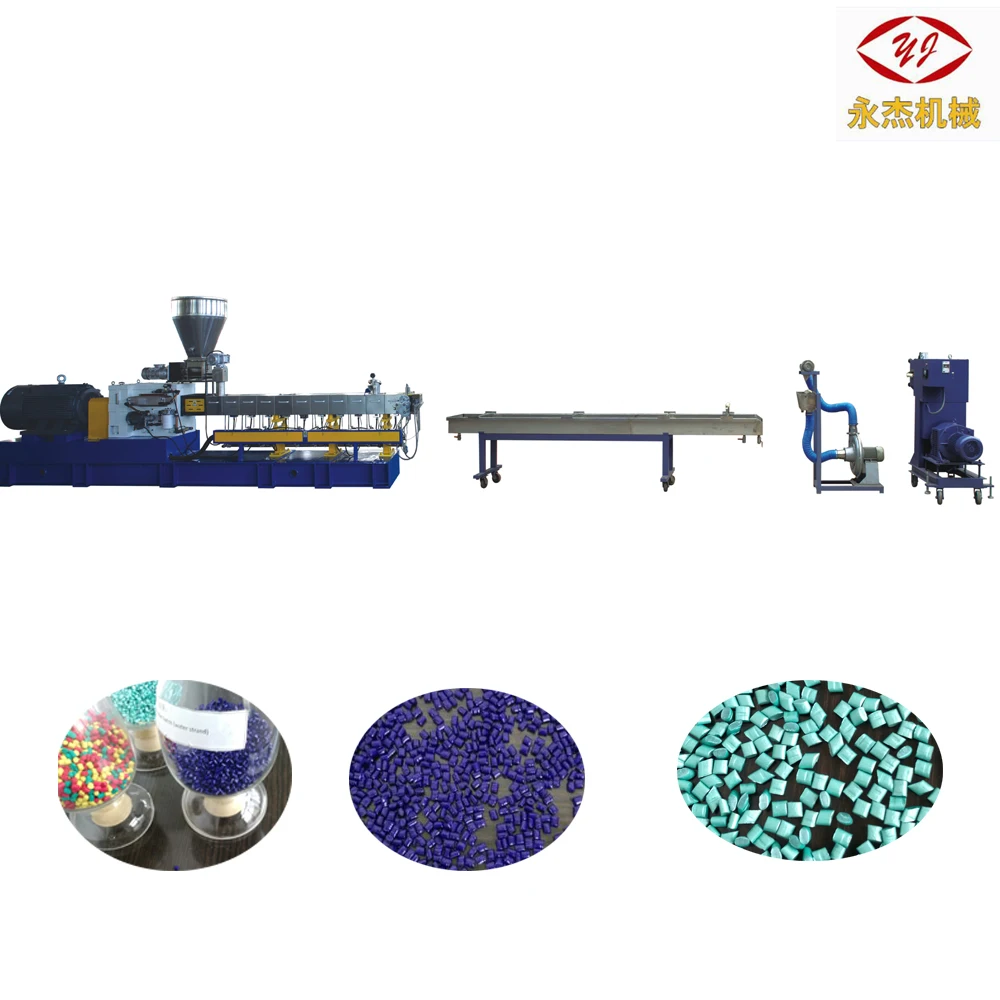

COMPLETE LINE:

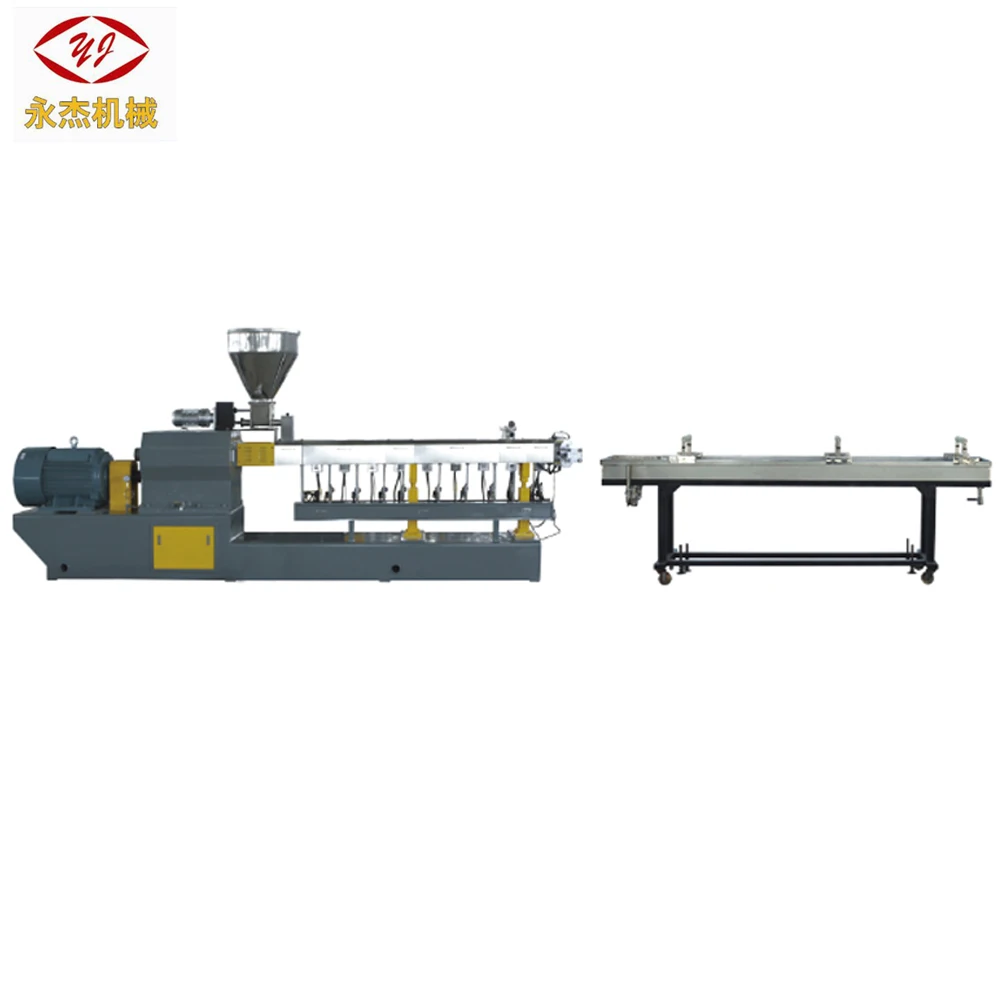

65D SIZE TWIN SCREW EXTRUDER:

75D SIZE TWIN SCREW EXTRUDER

:

SUB-MACHINE (water trough+dryer+cutter):

Application for water-cooling strand

1. Fiber reinforcement and modification: filling glass fiber or carbon fiber for: PP, PA, PBT,

ABS, AS, POM, PPS, PET, etc.

2. Ploymer compounding: PC+ABS, PA+ABS,CPE+ABS,PP+EPDM,PA+EPDM,

PA+SBS, etc.

3. Filling modified: Filling CaCO3,Talc,Titanium, carbon black for PVC PE,PP, EVA etc.

4. Cable material: cable sheath, cable insulation compounds, crosslinking compounds,

optical fiber protection compounds, cable coating material, thermal contraction material,

etc.

5. Dedicated material: PPR pipe compounds, PE crosslinking tube material, cigarettes

filter tip material, acetate fiber material, etc.

6. High Concentration Color Masterbatch: PE,ABS,PS,EVA,PET,PP + color +

additives, etc.

7. Flaming Retardants: PVC, PP, PA, ABS, EVA, PBT + flame retardants, etc.

8. Special Functional Masterbatch: double protection masterbatch, antistatic masterbatch,

anti-bacteria masterbatch, thermal insulation masterbatch, hypothermia material, etc.

9. The degradable masterbatch: PP, PE, PS + starch+ additives, etc.

Other product

Water-ring Hot-face pelletizing line

Pelletizing in the water line

Air-cooling hot-face pelletizing line

Air-cooling strand pelletizing line

FAQ

1. Are you a factory or trading company?

Both.

2. Where is your factory located? How can I visit there?

Our factory is located in industrial centralized area of Moling town, Jiangning, Nanjing, China.

(1) You can fly to Nanjing Airport directly. We will pick you up on Nanjing Lukou International airport;

(2) You can fly to Shanghai Pudong International Airport then come to Nanjing by High-speed railway, then we will pick you up in the railway station.

3. What's your advantages?

(1) Excellent quality control

(2) First-class service

(3) Professional Tech. and R&D team

(4) Quick manufacturing time

(5) Quite competitive price

4. How long is the delivery time?

Under normal conditions, products are delivered within 35 days.

5. How can I know the stauts of my order?

We will send you photos and videos of your order at different satge in time and keep you informed of the latest information.

6. how long is the warranty?

We can offer one-year warranty for the whole machine.

Contact us

Nanjing Yongjie Qixin Machinery Equipment Co.,Ltd

Nanjing Yongjie Chemical & Machinery Co.,Ltd

Add. : No.9 Lanxia Road, Moling Industrial Concentration Area, Jiangning District,211165, Nanjing, China

Tel.: 0086 25 52750152

Fax: 0086 25 58736139

Contact person:Annie

Mob/Whatsapp/Line/Wechat/Yahoo:0086 15026670964

Skype: annie at njyjhg.com(same as email)

Website: www.njyjhg.com