Сепарация твердых жидкостей непрерывная центрифуга с графином

- Категория: Separation Equipment >>>

- Поставщик: Zhengzhou,Toper,Industrial,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.33 $* | 0.75 $* |

| Aug-16-2025 | 0.89 $* | 0.65 $* |

| Jul-16-2025 | 0.95 $* | 0.95 $* |

| Jun-16-2025 | 0.27 $* | 0.7 $* |

| May-16-2025 | 0.42 $* | 0.76 $* |

| Apr-16-2025 | 0.57 $* | 0.50 $* |

| Mar-16-2025 | 0.51 $* | 0.3 $* |

| Feb-16-2025 | 0.1 $* | 0.57 $* |

| Jan-16-2025 | 0.42 $* | 0.42 $* |

Характеристики

Solid-liquid separation continuous decanter centrifuge, pusher centrifuge

Pusher centrifuge is a new kind of horizontal spiral centrifuge discharge, its working principle is to use solid - liquid specific gravity difference, and relying on centrifugal force field to make it thousands of times to broaden the solid phase was settling under the influence of centrifugal force, and then end solid-liquid parting, and the role of the body especially the discharge arrangements parting. Entire feed and parting process are successive, close, automatically ends. Centrifugal sedimentation method parting parting suspension components centrifugal machine.

Working principle of this pusher centrifuge.

Participate in the drum suspension liquid layer constituting the ring in the centripetal force, during which the solid particles settle to the drum wall to form sediment. Clear liquid overflow port or through the drum pipette discharged, said parting liquid. When parting ended with manual or mechanical methods discharged sediment. Solid particles in the drum wall settlement process, but also with the axial movement of the liquid stream, the feed is too large, the activity with the liquid to overflow port, but did not settle into fine particles in the drum wall with the parting liquid discharge drum, so that the parting was cloudy. Solid-liquid phase density difference is small, small solid particles or liquid viscosity of the suspension should be selected hard parting parting factor high sedimentation centrifuge drum extending the suspension stay in the moment (for example, reducing the amount of feed or use long drum, etc.), can ensure the parting was clarified.

Two types of pusher centrifuge.

Horizontal spiral centrifuge discharge settlement activity by the method can be divided into two kinds and countercurrent flow and, by parting the number of phases can be divided into two-phase and three-phase type parting parting type, according to the structure can be divided into ordinary distinction type, explosion-proof and airtight type three. Is a very broad use of centrifuges, mainly used to obtain relatively dry cake (solid phase deliquoring) or more clear parting liquid (liquid clarification). It can be used to leave a suspension of solid particles containing ≥0.005mm can also be used for classification of solid particles, the filter cloth is more suitable for regeneration of the parting material difficult, and the concentration of the particles of the suspension changes to a wider range of liquid, washing the filter cake also.

Widely application of pusher centrifuge.

Decanter centrifuge wider use, particularly applicable to centrifugal filtration of solid particles easily blocked due to filter media and filtration resistance is too large or fine particle suspension leave too much time loss, but the high moisture content of the sediment. Decanter centrifuge can be used to leave crystallization, chemical sediments, coal and other suspensions of various sewage sludge and animal and vegetable oils Cleaner clarification. Such as polyvinyl chloride, low-pressure polyethylene, polypropylene, starch, calcium carbonate, tail coal separation, animal fats purification, industrial wastewater and municipal sewage disposal, etc. Vertical decanter centrifuge is more appropriate in a sealed, explosion begged occasions.

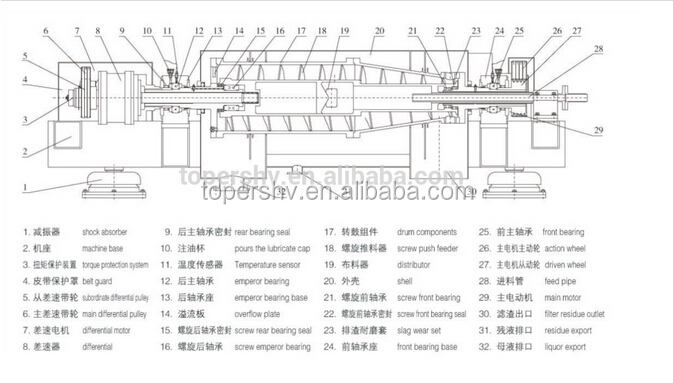

Pusher centrifugestructure

Technical parameters of automatic continuous centrifuge

Models | Basket Dia(mm) | Length-Diameter Ratio | Rotation rate of basket(r/min) | Relative Centrifugal force | Power of motor(Kw) | Weight(kg) | Overall Dimensions(l*w*h)(mm) |

LW220*660 | 220 | 3 | 4800 | 2840 | 7.5-11 | 900 | 1650*1150*700 |

LW220*880 | 220 | 4 | 4300 | 2280 | 7.5-11 | 1000 | 1850*1200*750 |

LW300*1140 | 300 | 3.8 | 3750 | 2370 | 11-15 | 1500 | 2100*1300*650 |

LW355*1160 | 350 | 3.3 | 4000 | 3100 | 22 | 2020 | 3067*920*1060 |

LW355*1460 | 350 | 4.1 | 4000 | 3100 | 22 | 2200 | 3365*920*1060 |

LW400*1200 | 400 | 3 | 3500 | 2750 | 18.5-22 | 2500 | 2400*1650*900 |

LW420*1680 | 420 | 4 | 3600 | 3000 | 22 | 2430 | 3320*1000*1060 |

LW450*1350 | 450 | 3 | 3500 | 3080 | 30 | 2230 | 3750*1090*1250 |

LW450*1800 | 450 | 4 | 3500 | 3080 | 30-37 | 3500 | 4200*1090*1250 |

LW530*1800 | 530 | 3.4 | 3200 | 3040 | 45-55 | 3920 | 4565*1230*1350 |

LW530*2120 | 530 | 4 | 3200 | 3040 | 45-55 | 4200 | 4885*1230*1350 |

We provide you reliable and fast package and variety kinds of transportation way to insure you get the goods in time and safely.

1.We have professional person on line to provide you comprehensive.easy-understanding and detail information and technical data about the machine you interested;solve your confusions or questions about the machine

2.Advise you the most suitable type of machine according to your requirement for your reference

3.Arrange the schedule if you pay a visit to our factory.

4.Our technical engineer can also come to help installation,operation test,solve problems and so on if required.

pusher centrifuge pusher centrifuge pusher centrifuge