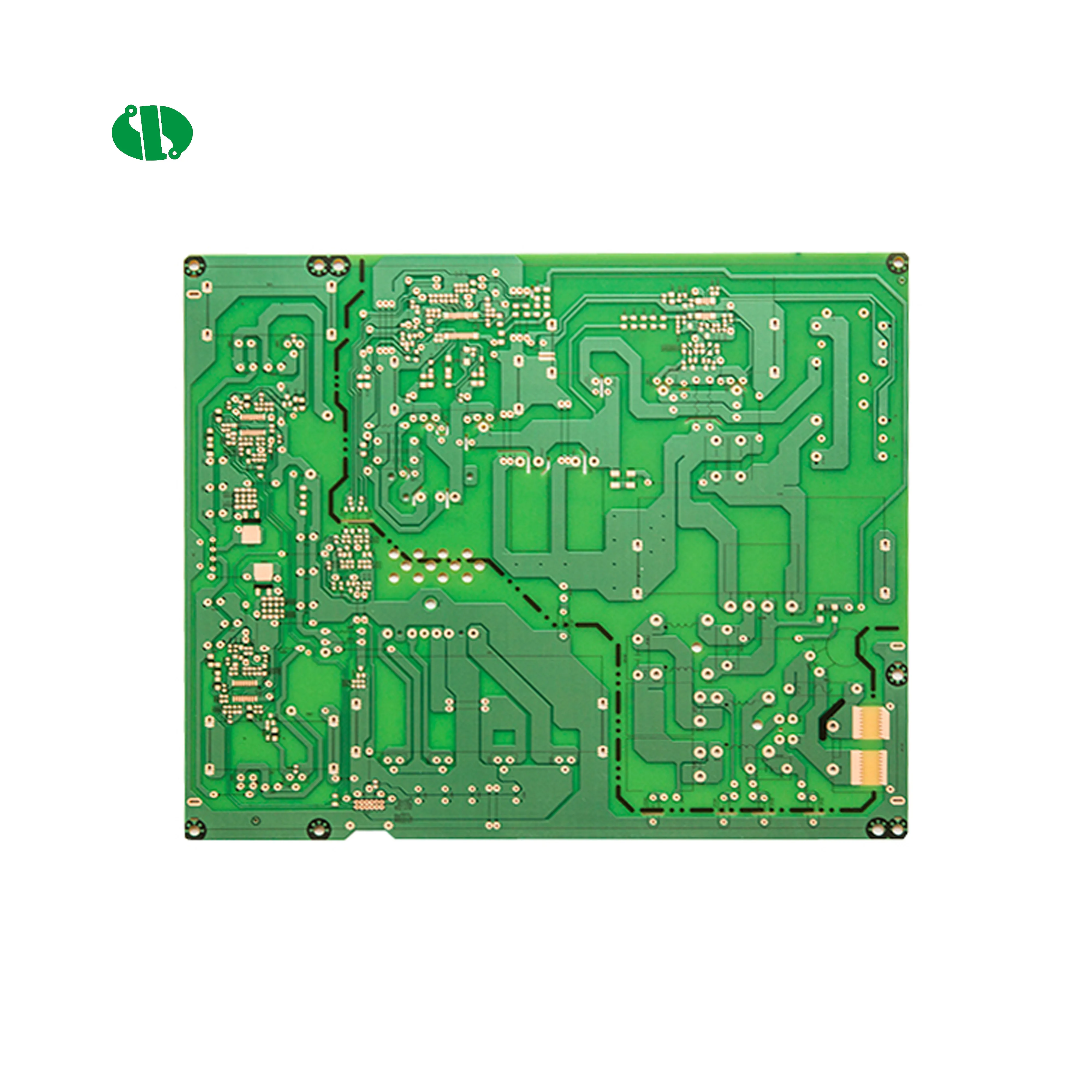

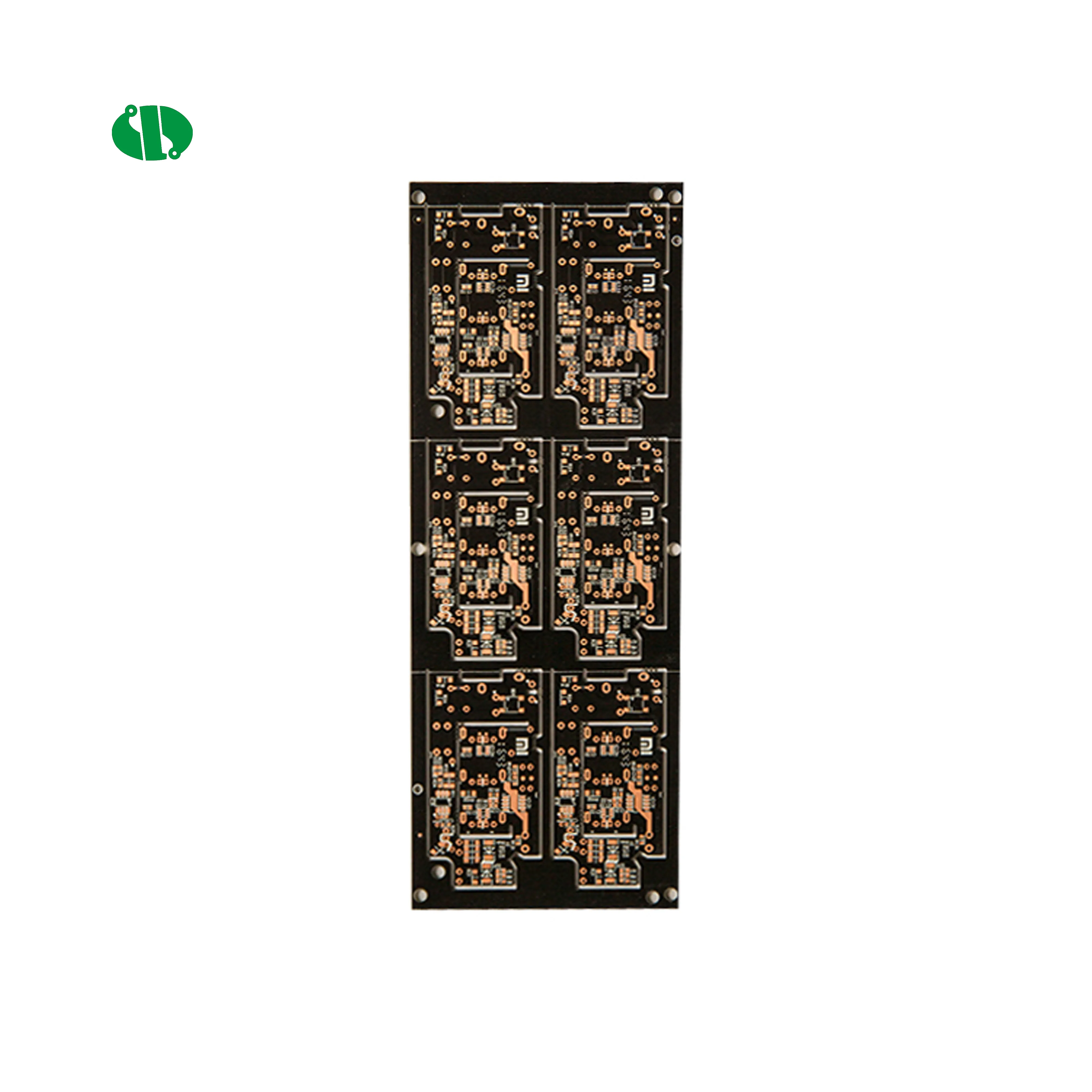

Двусторонняя

- Категория: Double-sided PCB >>>

- Поставщик: Hangzhou,New,Triunion,Electronics,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.87 $* | 0.88 $* |

| Aug-16-2025 | 0.22 $* | 0.54 $* |

| Jul-16-2025 | 0.20 $* | 0.63 $* |

| Jun-16-2025 | 0.56 $* | 0.76 $* |

| May-16-2025 | 0.5 $* | 0.83 $* |

| Apr-16-2025 | 0.59 $* | 0.82 $* |

| Mar-16-2025 | 0.12 $* | 0.93 $* |

| Feb-16-2025 | 0.54 $* | 0.13 $* |

| Jan-16-2025 | 0.97 $* | 0.94 $* |

Характеристики

Products Description

Specification

Layer Count(L) | Single and Double sided board | Copper Thickness(OZ) | 140um(4OZ) |

Production Panel Size(mm) | ≤610mm*440mm | Line Width/Space | 3/3mil |

Core Thickness(mm) | 0.05 | Hole Plating Aspect Ratio AR | ≤10:1 |

Dielectrict Thickness(mm) | ≧0.005 | Warpage | 0.60% |

BGA Pad Pitch(mm) | ≧0.4 | SMT Pitch (mm) | ≧0.5 |

Solder Mask Regisvation(mm) | ±0.038 | Impedance Controltolerance | ≧0.5 |

Inner Layer Clearance | ≧20 µm | Surface Treatment |

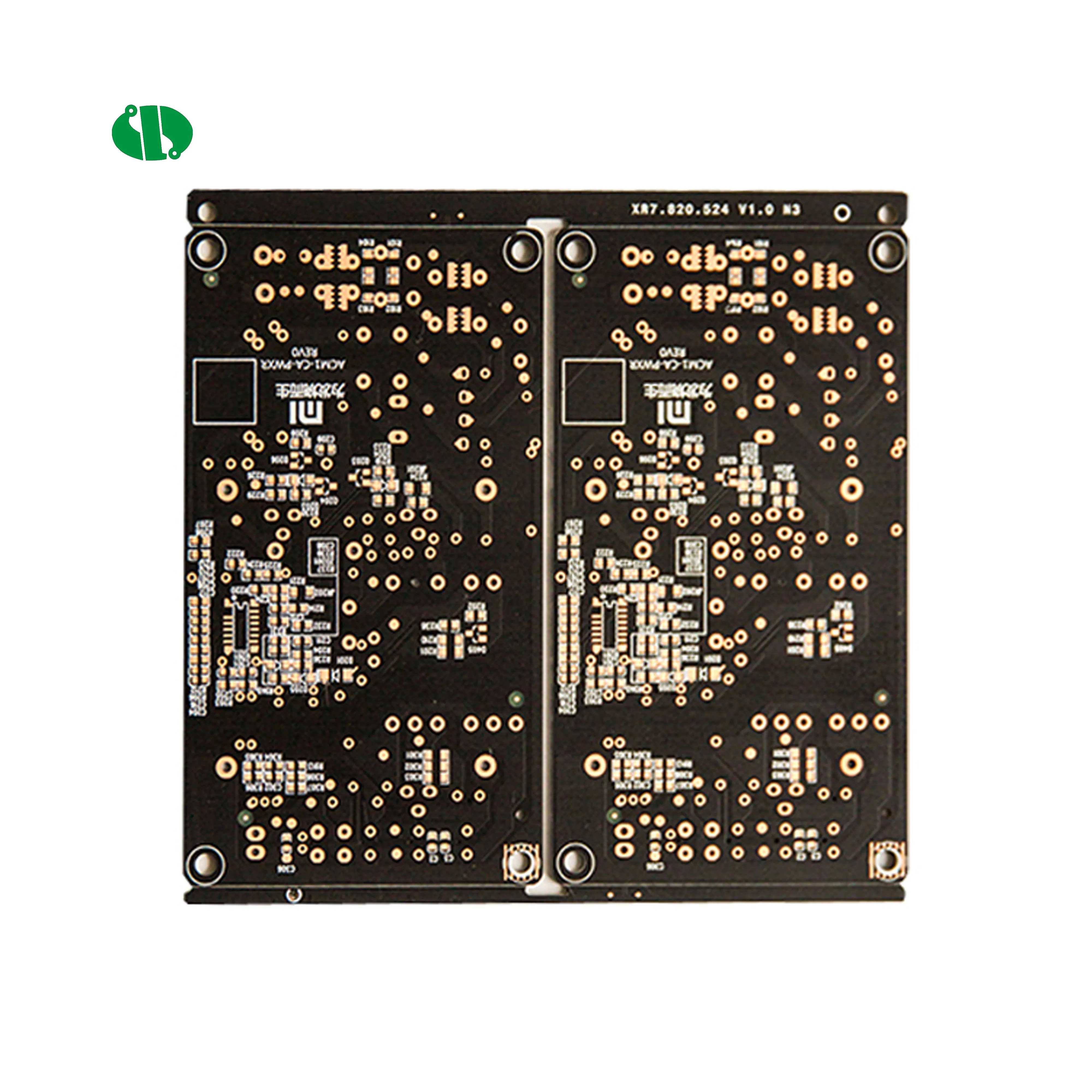

Comparison of the advantages and disadvantages of SCO、STH and PTH | ||||||||

Process | STH、SCO | PTH | ||||||

Advantages | 1. Simple process, and short production cycle; 2. Low production cost; 3.No “three wastes”, in line with environmental protection production standards. | 1. High reliability 2.Metallized holes can be shared with component holes | ||||||

Disadvantages | 1. low voltage; 2. Cannot be used for plug-in hole plug-ins; 3.The holes cannot be used for welding. | 1. The process is complex, long production cycle 2. The use of precious metal Pd activation solution, the price is higher. 3. Environmental pollution, electroless copper plating is the use of formaldehyde as a reducing agent; 4.The metallization quality of micropores is unreliable | ||||||

Application | 1. low voltage; 2. Cannot be used for plug-in hole plug-ins; 3.The holes cannot be used for welding. | Computers, aerospace, etc | ||||||

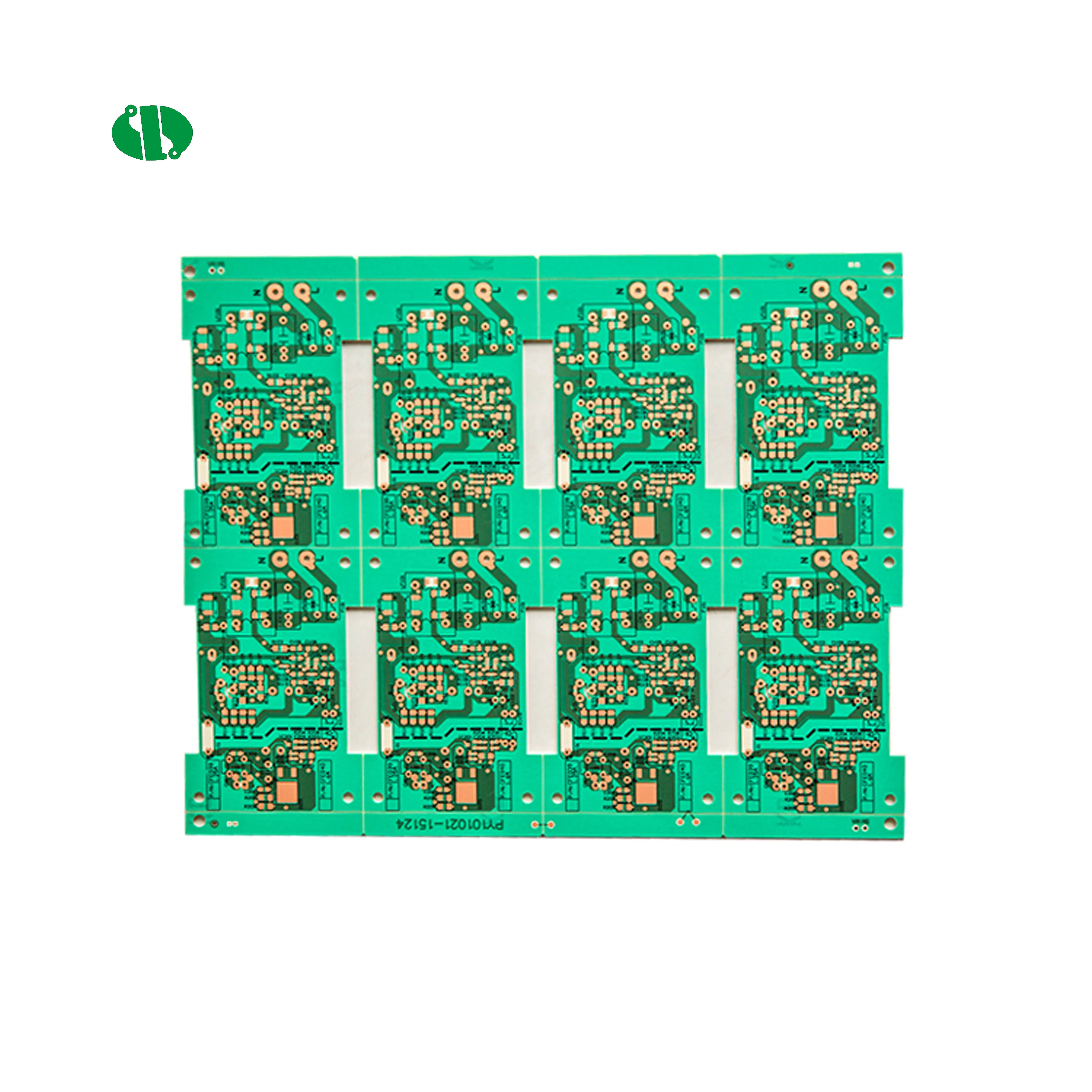

STH&SCO Process features:

1.The processing method is simple and the technology is easy to master;

2. The phenolic paper substrate of FR-1 can be used instead of the epoxy glass cloth board of CEM-3 and FR-4 to save the cost of substrate;

3. The use of physical method through the hole, saving a lot of water, electricity and heat sources required for the production of double panels;

4. Save a lot of precious metals, such as: copper, nickel, gold, tin, lead, etc., and there is no three waste pollution;

5. Suitable for large-scale assembly operations, shortening the production cycle of double panels.

2. The phenolic paper substrate of FR-1 can be used instead of the epoxy glass cloth board of CEM-3 and FR-4 to save the cost of substrate;

3. The use of physical method through the hole, saving a lot of water, electricity and heat sources required for the production of double panels;

4. Save a lot of precious metals, such as: copper, nickel, gold, tin, lead, etc., and there is no three waste pollution;

5. Suitable for large-scale assembly operations, shortening the production cycle of double panels.

Packing & Delivery

The inner packing is sealed plastic packaging(P.S:Humidity test paper can be attached.The outer packing is carton

Company Profile

About us

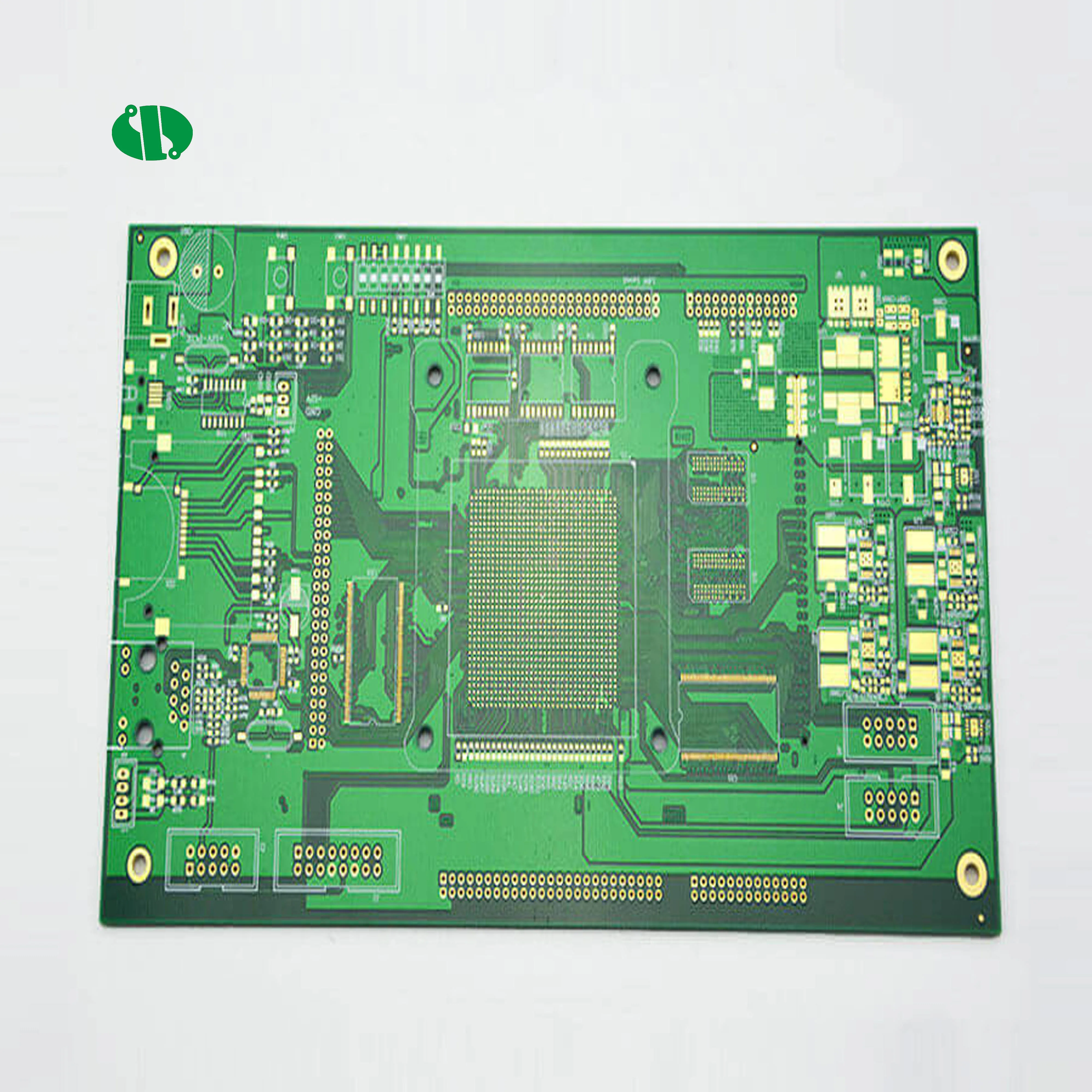

NEW TRIUNION ELECTRONICS CO., LTD. was founded in Hangzhou, Zhejiang in 1985. In 2011,Guangde Anhui manufacturing base was

established. Its main products are single, double-sided and multi-layer, STH and SCO PCBs.

For 38 years, NEW TRIUNION Electronics has been improving its comprehensive strengths all the way to be a high-level professional

PCB supplier both in modern management and production capacity.

established. Its main products are single, double-sided and multi-layer, STH and SCO PCBs.

For 38 years, NEW TRIUNION Electronics has been improving its comprehensive strengths all the way to be a high-level professional

PCB supplier both in modern management and production capacity.

Its PCB products are mainly involved in consumer and automotive electronics, industrial applications, and new energy industries,

serving well-known brands at home and abroad.

After completion of its second phase, the factory has been transformed into a digital one through optimizing its ERP and MES

system management. The factory hopes to develop together with its customers, making contribution to China’s growth as a global

technological power.

serving well-known brands at home and abroad.

After completion of its second phase, the factory has been transformed into a digital one through optimizing its ERP and MES

system management. The factory hopes to develop together with its customers, making contribution to China’s growth as a global

technological power.

Manufacturing Process Overview

Certifications

We carry out sustained implementation of 6S, TPM Management, and constantly improve the five management system to achieve the "zero defect" production goals. Providing customers with high quality and reliable products.

Technology is the wings, which help the enterprise take off. Our company has always prioritized technology research and development as business philosophy . At present, the company technology center is Hangzhou city-level technologycenters. Company has more than 40 research and development personnels . After a few years company developed product development and

technological innovation, and up to the present company have 40 patents, among them 6 invention patents, new utility model 29,3 appearance patents, two computer software copyright.

technological innovation, and up to the present company have 40 patents, among them 6 invention patents, new utility model 29,3 appearance patents, two computer software copyright.

Customer Distribution

IPC/EMS 35% | Industrial control, Precision motor, Aviation hydraulic, Various EMS products… |

Automotive electronics 30% | Battery management, On-board power supply, Brake control, Steering wheel, Water pump… |

Smart home 20% | Washing machines,Televisions, Refrigerators, Air conditioners, Water heaters, Microwave ovens… |

Consumer goods/Office supplies 10% | Printer, POS machine, Display, Game machine, Electric tool… |

Others 5% | Security control and monitoring system… |

Why Choose Us

1.Perfect Production Process Control System

2.Strict Product Quality Control and Testing System 3.Cooperate with Testing Laboratories in Professional Fields such as Automotive.Medical.Consumer Electronics.etc.

1.Absolute Time Control,On-time Delivery

2.OEM PCBA: 15 Days Delivery

3.ODM PCBA:Design+Prototype 30 Days Delivery

4.Component Sourcing: 7-15 Days Delivery

2.OEM PCBA: 15 Days Delivery

3.ODM PCBA:Design+Prototype 30 Days Delivery

4.Component Sourcing: 7-15 Days Delivery

1.PCB&PCBA Production Team with more than30 Years of Industry Experience

2.Advanced Production Equipment to Meet Different Production Needs

3.Subdivision of Production Lines in Professional Fields such as Automotive.Medical and Consumer Electronics

2.Advanced Production Equipment to Meet Different Production Needs

3.Subdivision of Production Lines in Professional Fields such as Automotive.Medical and Consumer Electronics