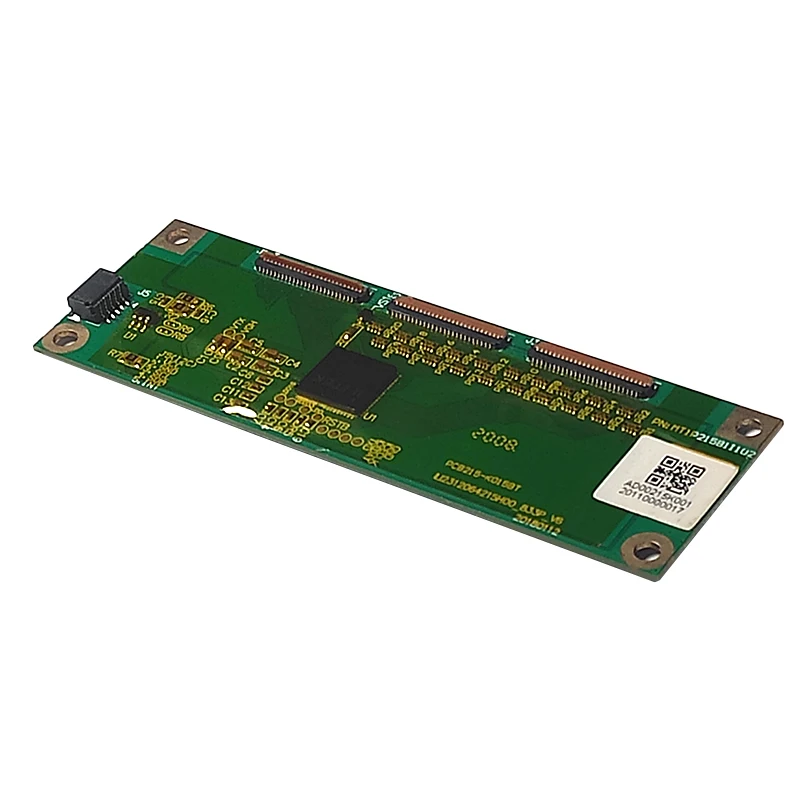

Shenzhen JERICO PCB бытовая техника Pcba образцы прототипов копирование GPS браслет часы Pcb сборка

- Категория: Double-sided PCB >>>

- Поставщик: SHENZHEN,JERICO,MULTILAYER,PCB,CO.,LTD.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.39 $* | 0.12 $* |

| Aug-16-2025 | 0.12 $* | 0.7 $* |

| Jul-16-2025 | 0.16 $* | 0.46 $* |

| Jun-16-2025 | 0.15 $* | 0.29 $* |

| May-16-2025 | 0.69 $* | 0.59 $* |

| Apr-16-2025 | 0.21 $* | 0.45 $* |

| Mar-16-2025 | 0.48 $* | 0.51 $* |

| Feb-16-2025 | 0.51 $* | 0.57 $* |

| Jan-16-2025 | 0.74 $* | 0.78 $* |

Характеристики

Products Description

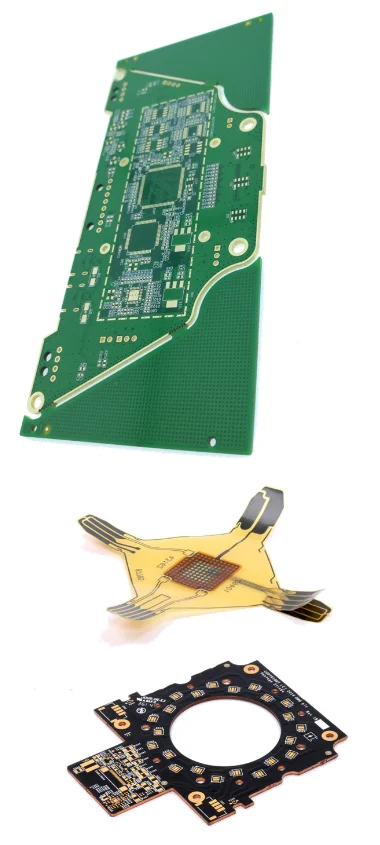

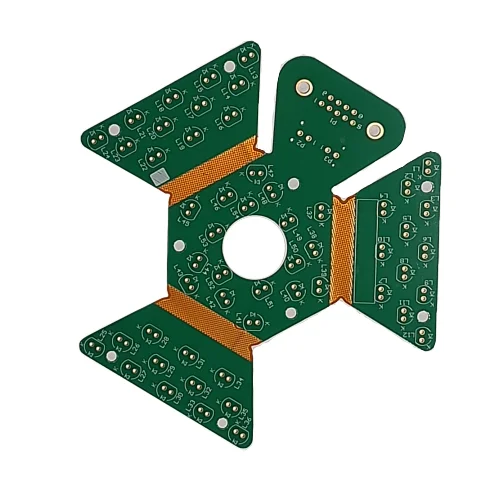

What is PCB, Rigid-Flex PCB, FPC and PCBA?

PCB is a Printed Circuit Board. It's an important electronic component, which is a support for electronic components and a carrier for electrical connections between electronic components.Rigid circuit boards are very popular largely due to their low cost. In conventional electronics, and particularly in consumer electronics, with greater space availability, manufacturers can save significantly by using rigid circuit boards.However, flexible PCBs are beginning to siphon market share from rigid circuit boards due to their versatility, among other advantages. PCBA is the whole manufacturing process of PCB bare board by SMT feeding and DIP plug-in.

Rigid PCB vs. Flex PCB

The most notable difference between rigid PCBs and flex PCBs (FPC) can be inferred from their names.

Rigid PCBs are inflexible, while flex PCBs can be bent or otherwise shaped to fit inside the designated system. Flexible circuits, when designed correctly, can also be flexed for hundreds of thousands of cycles repeatedly without failure. The increased versatility of flex boards typically comes at a higher cost, but they are essential for applications with limited space requirements, such as consumer electronics, medical devices, space and automotive applications.

What is Laser cut stencils?

This is also a subtractive process by which removal of the laser cut stencil foil material is achieved by laser cutting.

Naturally, laser cutting results in finer results and helps in achieving greater accuracy. Laser cutting also produces more

consistent results than the chemical etching process. Since the process is not dependent on the chemical conditions, there is essentially no requirement for protection from moisture.

Naturally, laser cutting results in finer results and helps in achieving greater accuracy. Laser cutting also produces more

consistent results than the chemical etching process. Since the process is not dependent on the chemical conditions, there is essentially no requirement for protection from moisture.

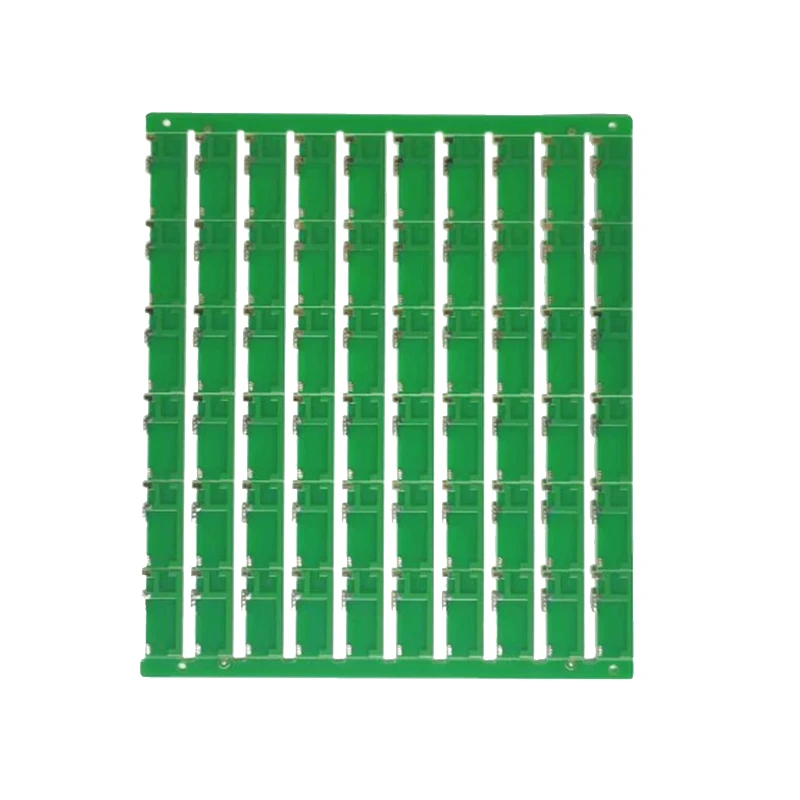

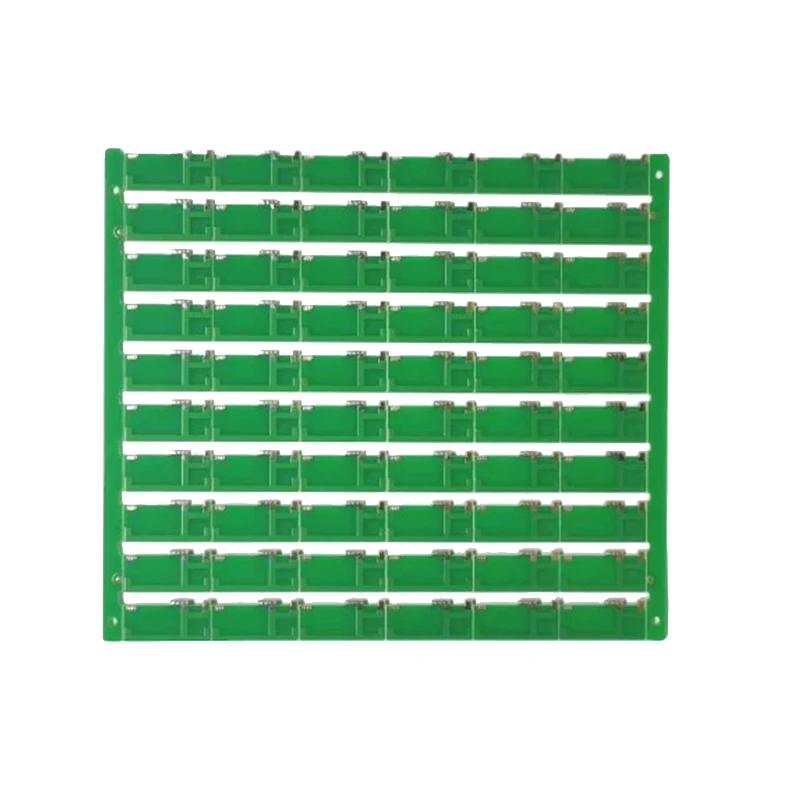

Support Customization

Double-sided PCB/ Multilayer PCB/ HDI PCB Board/ PCB Assembly (PCBA)/ Flexible PCB (FPC)/ Rigid-Flex PCB/ Single-sided PCB/ Aluminum PCB/ Metal Core PCB/ High Frequency PCB/ Other PCB

JERICO PCB in stable quality is worthy of your trust.

Manufacture Capability | |||||

Item | Capability | ||||

Base Material | FR-4/High TG FR-4/CEM1/CEM3/Halogen Free material/Rogers/Arlon/Taconic/Teflon | ||||

Layer Count | 1-18L | ||||

Finised Copper Thickness | 1-6oz | ||||

Finished Board Thickness | 0.2-7.0mm | ||||

Min. Hole Size | Mechanical Hole: 0.15mm | ||||

Laser Hole: 0.1mm | |||||

Outline Profile | Rout/V-cut/Bridge/Stamp Hole | ||||

Plugging Vias capability | 0.2-0.8mm | ||||

Board Thickness Tolerance | ±10% | ||||

Board Twist & Warp | ≤5% | ||||

Controlled Impedance | ±5% | ||||

Surface Finishing | HASL/HASL lead free/ENIG( Immersion Gold)/ Immersion Tin/Immersion Silver/OSP/etc. | ||||

UL Mark | E519316 | ||||

Lead time | 1-15 Days (Negotiable) | ||||

Material Identification Card | Yes | ||||

Innner Packaging | Vacuum Packed/ Paper Separated/ Others | ||||

Outer Packaging | Standard Carton Packed | ||||

Supply Ability | |||||

PCB | |||||

Layer Count | Quick Turn/Usual Time | Mass Production | |||

2L | 24hours/ 4-5days | 7-12days | |||

4L | 48hours/ 6-7days | 10-14days | |||

6L | 72hours/ 7-8days | 12-16days | |||

8L | 72hours/ 8-10days | 14-18days | |||

10L | 96hours/ 12-14days | 16-20days | |||

... | ... | ... | |||

Assembly | |||||

Quantity | Usual Time | ||||

<20pcs | 5days | ||||

20-100pcs | 7days | ||||

100-1000pcs | 10days | ||||

>1000pcs | Depend on BOM list | ||||

Marketing Campaign

Company Profile

Verified Certifications

Business Partners

Product Packaging & Shipping

FAQ

Q1: What files for PCB quotation?

A: Gerber, Protel 99SE, DXP, PADS 9.5, AUTOCAD, CAM350 are OK.

Q2: What other specifications you need to prepare if you want to get an quotation from us?

A: Please provide Quantity and Specifications like material, surface finish treatment, copper thickness, board thickness, soldermask color and silkscreen color and other special specs.

Please note that the above detail will speed up evaluation.

Q3: For PCBA quotation, what files format do JERICO need?

A: Gerber and BOM list, pick and place file. Please provide above information as well.

Q4: What is your minimum of quantity (MOQ) ?

A: There is no MOQ. We are able to handle small as well as large volume production with flexibility.

Q5: How can we guarantee you receive an good quality product?

A: For PCB, we will use Flying Probe Test, E-test etc. for it.

For PCBA, we will use SPI, AOI,X-RAY, FQC etc. for it.

>>>>>>Kindly send your inquiry to us, we will reply you within 12 hours even faster : )

A: Gerber, Protel 99SE, DXP, PADS 9.5, AUTOCAD, CAM350 are OK.

Q2: What other specifications you need to prepare if you want to get an quotation from us?

A: Please provide Quantity and Specifications like material, surface finish treatment, copper thickness, board thickness, soldermask color and silkscreen color and other special specs.

Please note that the above detail will speed up evaluation.

Q3: For PCBA quotation, what files format do JERICO need?

A: Gerber and BOM list, pick and place file. Please provide above information as well.

Q4: What is your minimum of quantity (MOQ) ?

A: There is no MOQ. We are able to handle small as well as large volume production with flexibility.

Q5: How can we guarantee you receive an good quality product?

A: For PCB, we will use Flying Probe Test, E-test etc. for it.

For PCBA, we will use SPI, AOI,X-RAY, FQC etc. for it.

>>>>>>Kindly send your inquiry to us, we will reply you within 12 hours even faster : )

Contact Us