5 тонн 8 10 автоматическая катушка разматыватель гидравлическая стальная с

- Категория: Metal Straightening Machinery >>>

- Поставщик: Henan,Dingkou,Industrial,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 7735.87 $* | 8122.95 $* |

| Aug-18-2025 | 7670.95 $* | 8054.58 $* |

| Jul-18-2025 | 6435.76 $* | 6757.87 $* |

| Jun-18-2025 | 7540.53 $* | 7917.44 $* |

| May-18-2025 | 6565.37 $* | 6893.39 $* |

| Apr-18-2025 | 7410.26 $* | 7781.40 $* |

| Mar-18-2025 | 7345.62 $* | 7712.9 $* |

| Feb-18-2025 | 7280.80 $* | 7644.43 $* |

| Jan-18-2025 | 7215.78 $* | 7576.90 $* |

Характеристики

DESCRIPTION

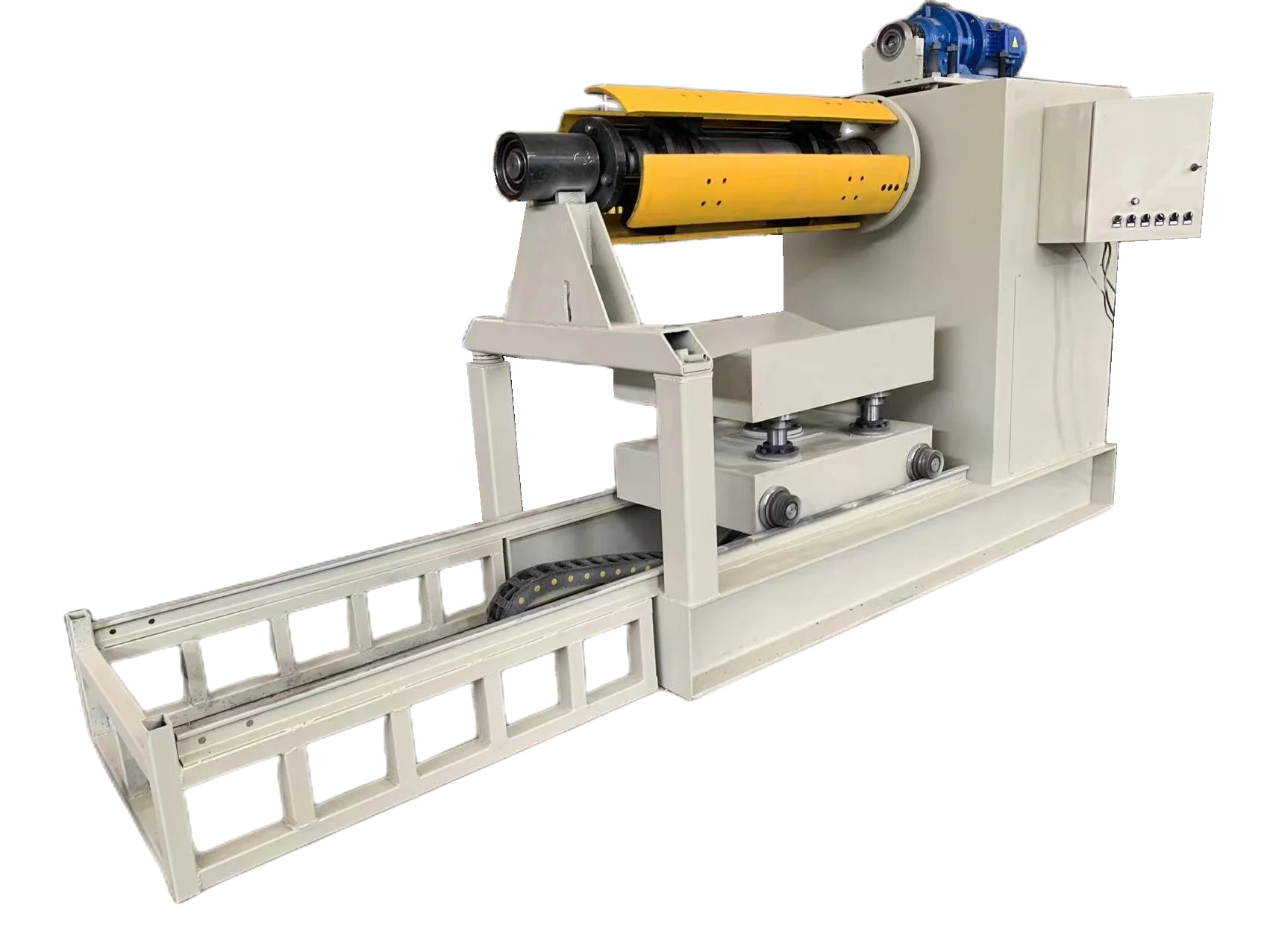

Full Automatic 5T 10T Hydraulic Uncoiler Color Steel Aluminum Galvanized Coil Sheet Decoiler Machine

Now there are many types of decoliers in Decho , rougly we divide them into three types: Hydraulic drives, electric drives and manual operation version.Those decoilers could be used with many types machine like slitting machine, cutting machine, leveling machine and others.

We are involved in manufacturing and export a comprehensive range of decoilers and uncoilers. Fabricated as per set industrial standards, our range of available in both motorized and non-motorized form. Stringently checked on quality parameters, these are available in various capacities and specifications to meet variegated demands of clients.

Hydraulic decoiler for the metal slitting line is designed to match lots of heavy duty metal processing tools. For the hydraulic decoiler we design with 5 ton, 7 ton, 8 ton, 10 ton, 25 ton and even to 30 ton double head decoiler. We can design hydraulic decoiler according to your requirements.

Hydraulic decoiler for the metal slitting line is designed to match lots of heavy duty metal processing tools. For the hydraulic decoiler we design with 5 ton, 7 ton, 8 ton, 10 ton, 25 ton and even to 30 ton double head decoiler. We can design hydraulic decoiler according to your requirements.

Specifications:

We customize the machine according to customer's requirements and can be used for a wide variety of profiles.

Product Name | Hydraulic decoiler |

Suitable Material | Cold rolled sheet, galvanized sheet,stainless steel sheet. |

Suitable Thickness | 0.3-1.5 mm |

Max Width of Material | 1250 mm |

Max Loading Weight | 10T |

Inner Diameter | 508 mm |

Outer Diameter | 1200 mm |

Diameter of Main Shaft | ø90 mm |

Uncoiling Speed | 0-40 m/min, step-less. |

Decho offers a wide range of products and good solutions for companies operating in sheet metal, construction, manufacturing industries. Our products include:

Roofing roll forming machine / Caping_Nok roll forming machine / Louver roll forming machine / Pressing curve forming machine / Floordeck roll forming machine / Truss roll forming machine / Channel roll forming machine / Ceiling roll forming machine / Slitter & cutter / Leveling & cutting to length machine / Bending machine / Decoiler (uncoiler)

Details of Roof Ridge Cap Roll Forming Machine:

Configuration is not unique, we will customize a number of program for you, to provide you with more options.

Control System Of Hydraulic Decoiler

The hydraulic uncoiler is in both Chinese and English, with multiple color buttons, which is easy to identify and identify products, simple to operate, and low technical requirements.

The company has a variety of types of uncoilers, manual, electric, hydraulic, support color and logo customization.

The company has a variety of types of uncoilers, manual, electric, hydraulic, support color and logo customization.

Support Arm Of Hydraulic Decoiler

to rotate at the same time.

Three arms expanding device with sliding block can provide more powerful force to fixing the coil, The synchronous action can

avoid the deformation of the coil.The block installed on the the arms can suit the coils with bigger inner diameter.

Feed Car Of Hydraulic Decoiler

The feeding trolley can move forward and backward, and lift up and down. The steel coil is placed on the support arm through the feeding trolley, thus realizing automation, simple operation and labor saving.

Full automatic hydraulic uncoiler supports customization of various widths and weights. For more information, please contact us.

MORE FOR YOU CHOOSE

DETAIL IMAGES

Product Features Of Full Automatic 5T 10T Hydraulic Uncoiler Color Steel Aluminum Galvanized Coil Sheet Decoiler Machine

(1) Automatic Operation

Decoiler rotation is automatically loop arm controlled. The loop arm controls variable speed operation, providing smooth stops and starts. Variable speed reduces decoiler.

(2) Safety

The decoiler rotary drive system and mandrel expansion power is fully guarded. The pendant control allows disabling automatic rotation during coil loading.

(3) Electrical Requirements

Three phase electrical supply is required. Equipment can operate from 220-575 volts in 50 or 60 hz.

(4) Construction

Construction includes steel plate and heavy structural sections. Plate seams are seal welded. Structural bracing is included where required. Mandrel expansion & contraction is by a link system including bronze bearings.

(5) Decoiler Finish

After fabrication completion, the decoiler framework is machine cleaned and powder coated prior to electro-mechanical assembly.

(6) Coil Car

A coil car with weight capacity matched to the specified decoiler can be included. The coil car includes a 'v' shaped surface to center coils during movement. The coil car includes sufficient vertical travel to touch the mandrel lower surface when fully extended. The powered coil car moves along steel tracks mounted within the decoiler base. Hydraulic check valve prevents vertical coil drop in the event of hydraulic pressure loss.

(7) Installation

The decoiler and coil car can be installed by placing on a typical industrial concrete foundation and drilling holes for concrete expansion bolts.

Decoiler rotation is automatically loop arm controlled. The loop arm controls variable speed operation, providing smooth stops and starts. Variable speed reduces decoiler.

(2) Safety

The decoiler rotary drive system and mandrel expansion power is fully guarded. The pendant control allows disabling automatic rotation during coil loading.

(3) Electrical Requirements

Three phase electrical supply is required. Equipment can operate from 220-575 volts in 50 or 60 hz.

(4) Construction

Construction includes steel plate and heavy structural sections. Plate seams are seal welded. Structural bracing is included where required. Mandrel expansion & contraction is by a link system including bronze bearings.

(5) Decoiler Finish

After fabrication completion, the decoiler framework is machine cleaned and powder coated prior to electro-mechanical assembly.

(6) Coil Car

A coil car with weight capacity matched to the specified decoiler can be included. The coil car includes a 'v' shaped surface to center coils during movement. The coil car includes sufficient vertical travel to touch the mandrel lower surface when fully extended. The powered coil car moves along steel tracks mounted within the decoiler base. Hydraulic check valve prevents vertical coil drop in the event of hydraulic pressure loss.

(7) Installation

The decoiler and coil car can be installed by placing on a typical industrial concrete foundation and drilling holes for concrete expansion bolts.

This auto uncoiler is used to support the coil for roll forming machine

1. Automatic uncoiler is an auxiliary equipment for roll forming machine.it is composed of feed main machine, hydraulic station and control system.

When it works together with roll forming machine and auto stacker, they make up a completely steel panel production line.

2. The working process is loading coil→expanding to fix the coil→uncoiling→feeding the sheet into roll forming machine.

3.The advantage for automatic uncoiler is, highly automatic, high producing efficiency, and low labor cost.

There is a sensor, to keep uncoiler goes at the same speed as roll forming machine.

When it works together with roll forming machine and auto stacker, they make up a completely steel panel production line.

2. The working process is loading coil→expanding to fix the coil→uncoiling→feeding the sheet into roll forming machine.

3.The advantage for automatic uncoiler is, highly automatic, high producing efficiency, and low labor cost.

There is a sensor, to keep uncoiler goes at the same speed as roll forming machine.

PACKING & SHIPPING

ABOUT US

FAQ

Q1: How long is the warranty?

Q2: Can I have my own customized product?

A1: We guarantee a 12-month after-sale service .Any problem when using ,call or mail us ,we will advise on technically sound methods .If needed ,we will provide free accessories.

Q2: Can I have my own customized product?

A2: Yes, just send the customized color, logo, pattern, packaging, box label and so on.

Q3: How can I get sample and how long will it take?

A3: Sample policy is different for different items. Please kindly contact us to get details.

Q4: What's the MOQ?

A4: MOQ is different for different items, please kindly contact us for confirming.

Q5: How do I pay for my purchase order?

A5: T/T, L/C at sight, Western Union, MoneyGram.

Q6: What is your terms of payment?

A6: For regular order, T/T 30% as deposit, and 70% before Shipment. We'll show you the photos of the products and packages before you pay the balance.

Q7: How about your delivery time?

A7: Generally, It will take about 7~15 days to send goods out. The specific delivery time depends on the items and the quantity of your orde.

Q3: How can I get sample and how long will it take?

A3: Sample policy is different for different items. Please kindly contact us to get details.

Q4: What's the MOQ?

A4: MOQ is different for different items, please kindly contact us for confirming.

Q5: How do I pay for my purchase order?

A5: T/T, L/C at sight, Western Union, MoneyGram.

Q6: What is your terms of payment?

A6: For regular order, T/T 30% as deposit, and 70% before Shipment. We'll show you the photos of the products and packages before you pay the balance.

Q7: How about your delivery time?

A7: Generally, It will take about 7~15 days to send goods out. The specific delivery time depends on the items and the quantity of your orde.