Машина для производства панелей из базальтового камня и

- Категория: Other Construction Material Making Machinery >>>

- Поставщик: Henan,Fantianliang,Machinery,&,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-15-2025 | 7619.29 $* | 7771.51 $* |

| Jul-15-2025 | 6179.83 $* | 6303.90 $* |

| Jun-15-2025 | 7499.81 $* | 7649.53 $* |

| May-15-2025 | 7439.54 $* | 7588.12 $* |

| Apr-15-2025 | 5939.89 $* | 6058.52 $* |

| Mar-15-2025 | 7319.0 $* | 7465.87 $* |

| Feb-15-2025 | 7259.35 $* | 7404.64 $* |

| Jan-15-2025 | 7199.59 $* | 7343.54 $* |

Характеристики

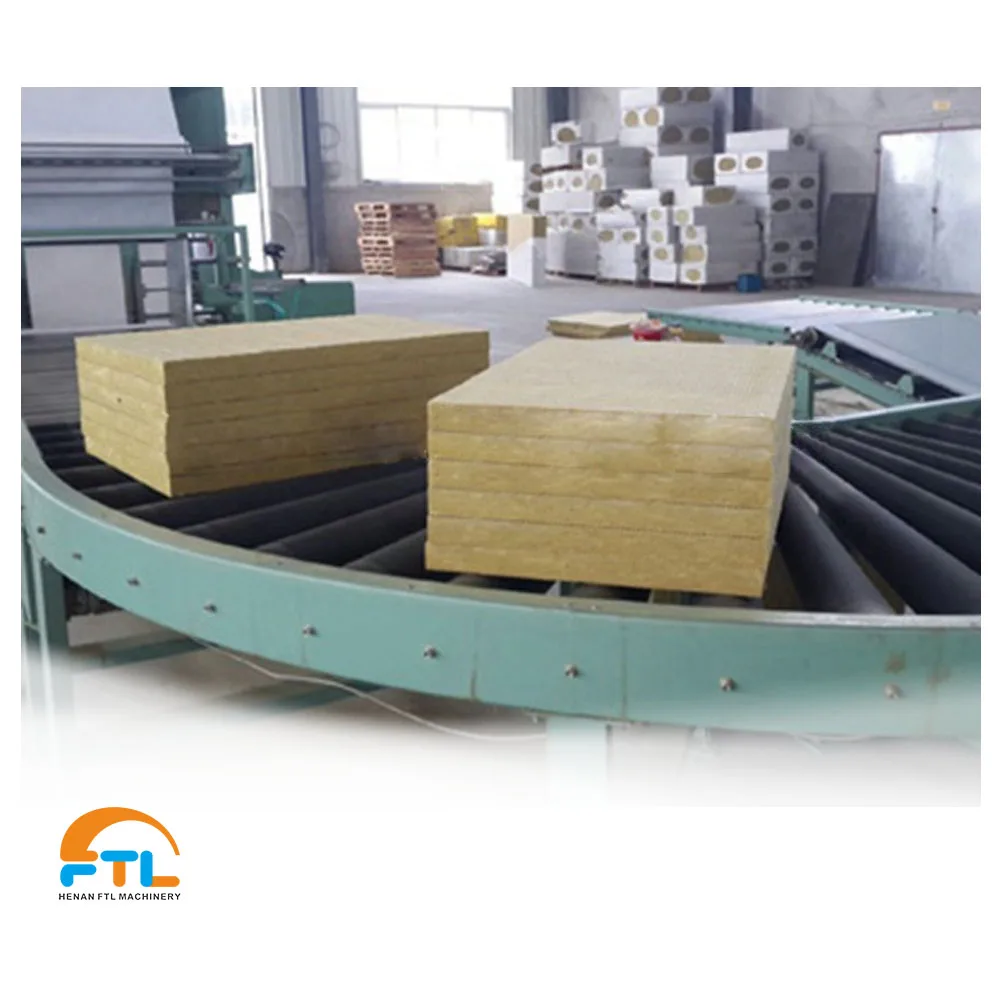

Basalt stone wool panel machine insulation rock mineral wool fiber board production line cutting machine

Rock Wool is mainly used for fireproofing and sound absorption of partition walls and curtain walls, thermal insulation of roofs,retaining structures and geothermal systems as well as thermal insulation and fireproofing of industrial kilns, ovens, large sized tanks and vessels, etc

Rock Wool Product Specifications:

1. Width: 1,000mm or 1,200mm

2. Length: 1,000mm (adjustable)

3. Thickness: 30-150mm

4. Density: 40-200kg/m³

Rock Wool Product Technical Parameters:

1. Fiber diameter: 5-8um

2. Shot content: 6-8%

3. Max. application temperature: 600oC.

1) High quality and extra fine, low slag-ball content and low coefficient of heat conductivity.

2) Wide range of bulk density (60kg-300kg/m3 ), wide range of specifications with all data being within/better than nationalstandards.

3) Wide range of applications for construction, petroleum,electric power metallurgy, textile, national defence, transportation andother industries. Ideal material for heat insulation and sound insulation of industrial facilities such as tank, boiler, flue, heat exchanger, blower,vehicles and ships etc.

4)Owing to our large scale production and advanced technology the products are salable in home market, as well as overseas markets.