Поставщик хорошее качество школьная вязальная машина запасные части

- Категория: Sock Knitting Machines >>>

- Поставщик: Shenyang,Innold,Machinery,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 4010.72 $* | 4211.25 $* |

| Aug-19-2025 | 3977.51 $* | 4176.14 $* |

| Jul-19-2025 | 3336.92 $* | 3503.33 $* |

| Jun-19-2025 | 3909.55 $* | 4104.34 $* |

| May-19-2025 | 3404.62 $* | 3574.98 $* |

| Apr-19-2025 | 3842.68 $* | 4034.84 $* |

| Mar-19-2025 | 3808.47 $* | 3998.1 $* |

| Feb-19-2025 | 3774.1 $* | 3963.62 $* |

| Jan-19-2025 | 3741.9 $* | 3928.92 $* |

Характеристики

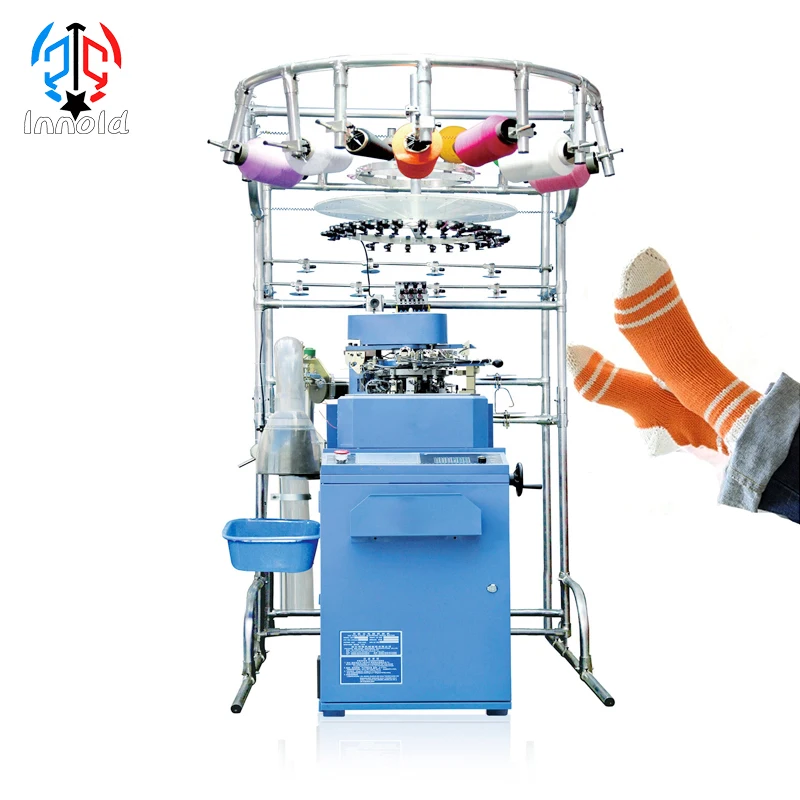

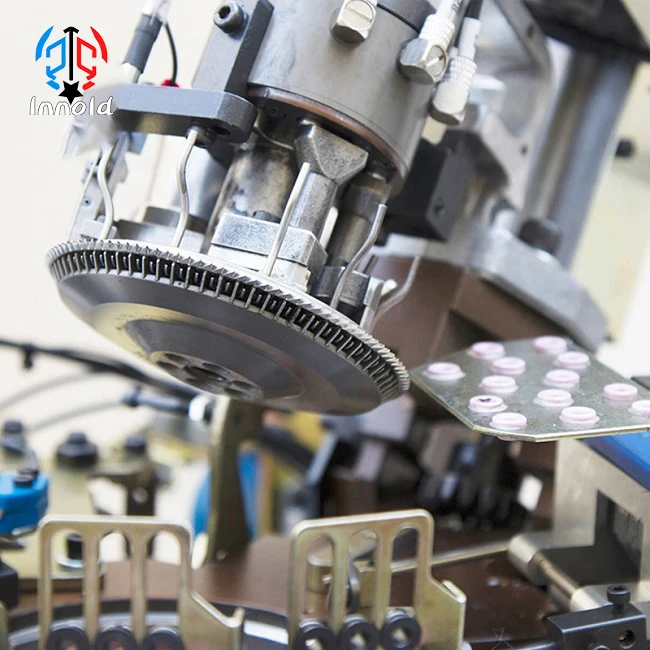

Supplier Good Quality School Knitting Machine Spare Parts Maker Socks

This sock machine can weave flat lines, wool circles, arbitrary coils, jets, collects, mesh, double Lukou and other organizations. It is widely used in multi -colored floating flowers, invisible socks, three -dimensional socks, cartoon socks, and The production of full rubber bands, business socks, business socks, and casual socks.

Machine parameters of Socks Machine Spare Parts:

| Model | ID-6FP/ID-6FMP/ID-6FPI | |

| Cylinder Diameter | 3+1/2 | |

| Needle Range | 84-220N | |

| Running Speed | 280-360PM | |

| Power Required | Servo Motor | 0.85kw |

| Fan Motor(Optional) | 1.10KW | |

| Control Box | 0.80KW | |

| Floor Space | 1500*1200*2400MM | |

| Net Weight | 300KG | |

| Gross Weight | 350KG | |

| Packing Dimension | 940*740*1600mm 39sets for a 40GP 18sets for a 20GP | |

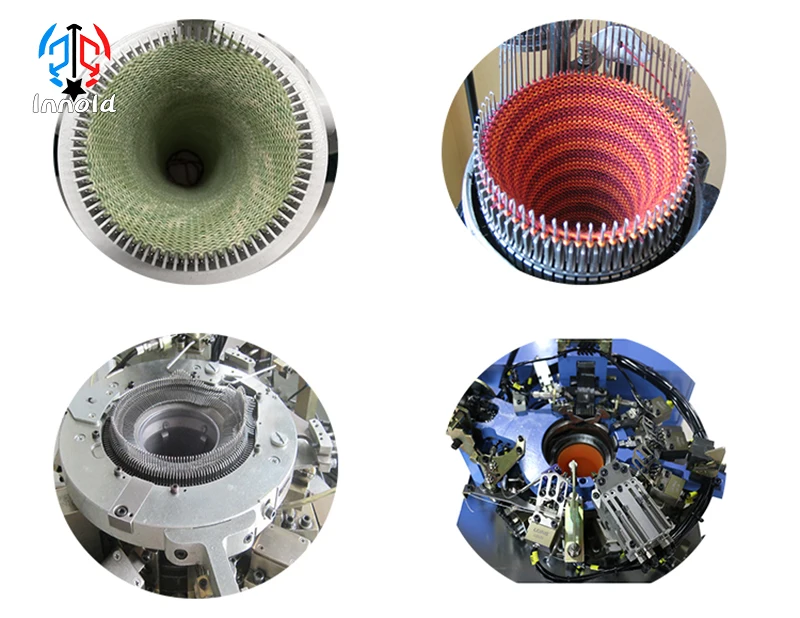

Features&Functions of Socks Machine Spare Parts:

1. Each line maybe weave with a main color and five auxiliary color,each sock may be knitted with sixteen colors.

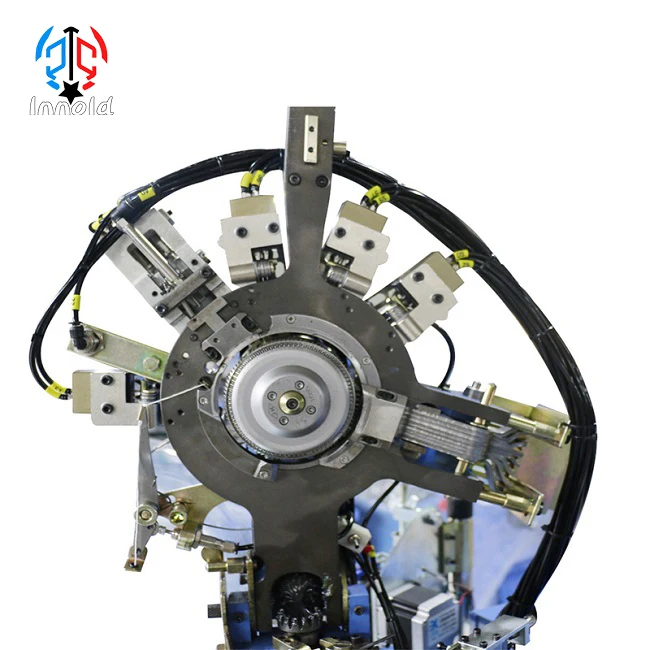

2. Suitable to power 380V/50Hz or 220V/50Hz,the whole knitting system is controlled by computer.

3. UPS system to preserve the memory of program and knitting process in case of temporary power failure when power is restored,machine can continue knitting to reduce the loss and watse.

4. Equipped with USB prot for easy data reading and storage with USB falsh drive.

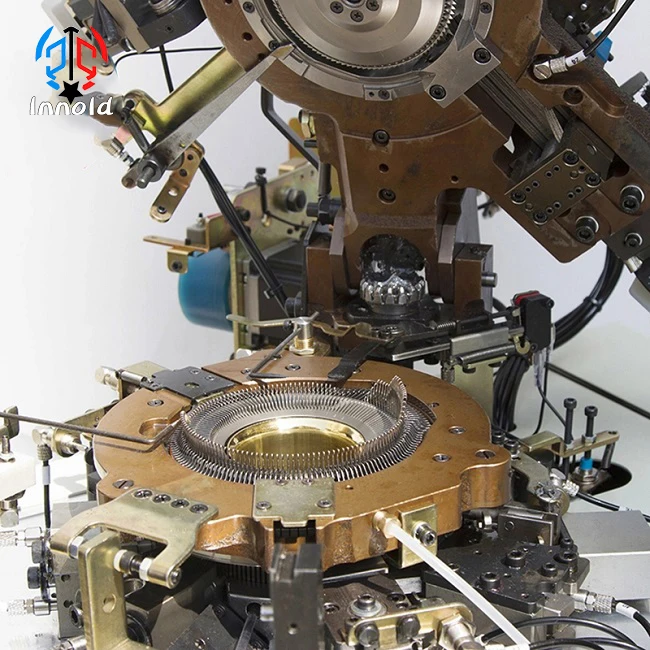

5. Double-picker design during heel knitting.The productivity and knitting quality are superior than the tarditional singel-picker machine.

6. All material of needles system is adopted the technology of Japan,and have a good stability and durability.

7. Drumless and full computerzied control system.

8. Stepping motor to control elastic yarn feeder for various course sizes,with options of single or two colors.

9. Automatic lubrication system.The oil injection is controlled by microcomputer.

10. LCD panel,with various languages available for choices to display error message,processing reference production quantity,speed and so on.It allows the operator to easily montior and control the machine conditions.

11. Stitch quality,speed,course length,size,quantity,pattern,chain program,etc.can be controllde and set up by machine computer panel.

12. Large memory capacity for storage of more pattern programs.

13. Auto testing,error sensors and self-protection system.

14. New version of graphic design system.User friendly,easy to learn and operate.PIC and BMP format both acceptable.