1000 кг/ч машина для производства туалетного мыла с полным покрытием заводская цена потеря

- Категория: Other Chemical Equipment >>>

- Поставщик: Nantong,Tongji,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.42 $* | 0.76 $* |

| Aug-15-2025 | 0.54 $* | 0.53 $* |

| Jul-15-2025 | 0.53 $* | 0.39 $* |

| Jun-15-2025 | 0.12 $* | 0.49 $* |

| May-15-2025 | 0.92 $* | 0.95 $* |

| Apr-15-2025 | 0.96 $* | 0.8 $* |

| Mar-15-2025 | 0.38 $* | 0.28 $* |

| Feb-15-2025 | 0.90 $* | 0.25 $* |

| Jan-15-2025 | 0.66 $* | 0.45 $* |

Характеристики

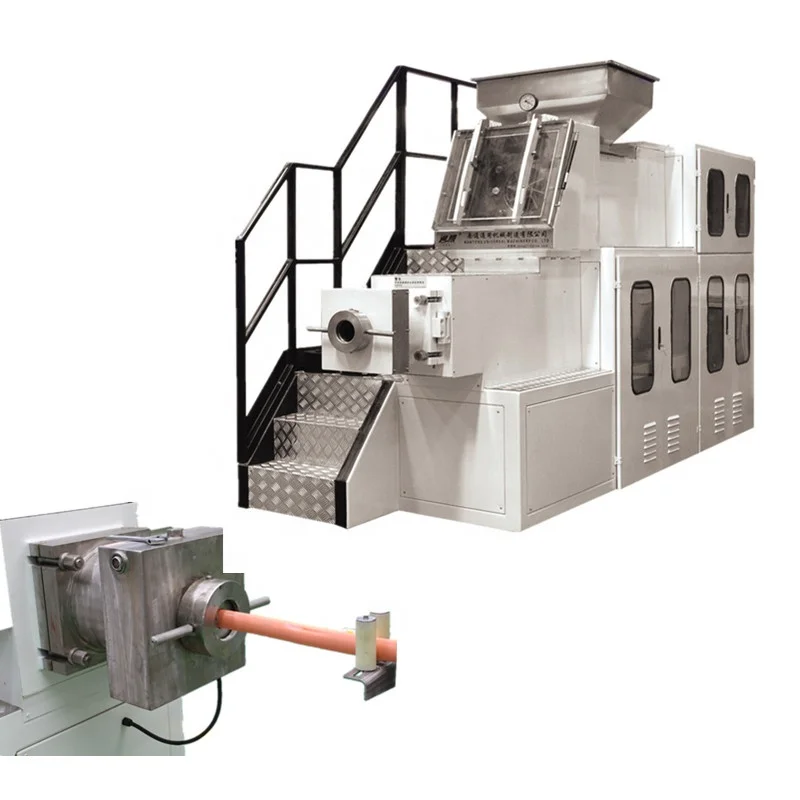

Tongji 1000kg/h Toilet/Laundry soap production line

Our company can provide laundry or toilet soap making finishing line from soap noodles:

1. Laboratory soap machine ( make soap no more than 100g)

2.100kg/h or 150kg/h soap machine

3.300kg/h, 500kg/h,1000kg/h,2000kg/h,3000kg/h,4000kg/h,5000kg/h soap making finishing line

No | Machine | Optional | ||

Z1 | XZJ250 Mixer | XZJ250 | ||

Z2 | S450P Three Roll Mill | S450P | ||

Z3 | S450P Three Roll Mill | S450P | ||

Z4 | XCT1000 Duplex Plodder | XCT1000 | ||

Z5 | XQK/G300 Embossing & Cutting Machine | XQK/G300 | ||

Z6 | XLD200 Stamper | XLD200 | ||

Conveyor | ||||

Platform and Utilities | ||||

F1 | Steel Operation Platform | |||

F2 | 1m3/m Air Compressor | |||

F3 | Plodder Vacuum pump VT4.25 | |||

F4 | Stamper Vacuum Pump KVT3.60 | |||

F5 | S400-WLH High Temperature Chiller | |||

F6 | S200-WL Low Temperature Chiller | |||

Moulds | ||||

M1 | Mould for Embossing Cutter | |||

M2 | Mould for XLD200 Stamper | |||

500kg/h finishing line main machines:

Mixer.

Power:11kw

Three Roll Mill .

The Three Roll Mill is used for soap refining. Three rolls are horizontally placed with different rotating speeds. The refining function is achieved by pressing and squeezing force between the adjacent rolls. The main frame is made of high quality stain structure, strong and solid. All gears are precisely manufactured and bathed in oil lubricants for long running life with lower noise, less wearing and better reliability. Rolls are made of special alloy, high hardness, anti-wearing capability, and with water chilling system. Gap between rolls can be adjusted easily for different refining effects and production capacity needs.

Roll Diameter (mm)\t260

Roll Length (mm)\t675

Power (KW)\t11

Duplex Plodder.

This machine has two stages, driven by independent driving and transmission system. The first plodder is acting as a simplex refiner to make soap pellets in the vacuum condition. In the final plodder, the soap is pressed and extruded out in billets through the orifice to feed the downstream cutter or stamper. The integrated motor and gear box has higher driving efficiency, and with specially designed sealing, it can avoid the oil leakage from the gearbox into the screw chamber to cause soap contamination. The lengthened screw chamer design can reach 1:6 for the screw diameter vs effective barrel length, which can extrude the material effectively and increase the compactness. The barrel inner body is made of high quality seamless stainless steel, without any water leakage. The refining plate or net can be installed on the first plodder front part to enforce the martial refining effects to optimization. The final plodder speed can be adjusted by VFD. There is a level sensor on the vacuum chamber door to realize the auto run and stop control of the first plodder. Specially designed and continuously improved water cooling system and the different screw inner diameter and pitch design are especially suitable for the laundry soap and toilet soap. Except the aluminum screws, all parts contacting with soap are made of high quality stainless steel.

Screw Diameter(mm)\t200\t

Screw Speed(rpm)\t18/18\t

Motor Power (KW)\t15+15

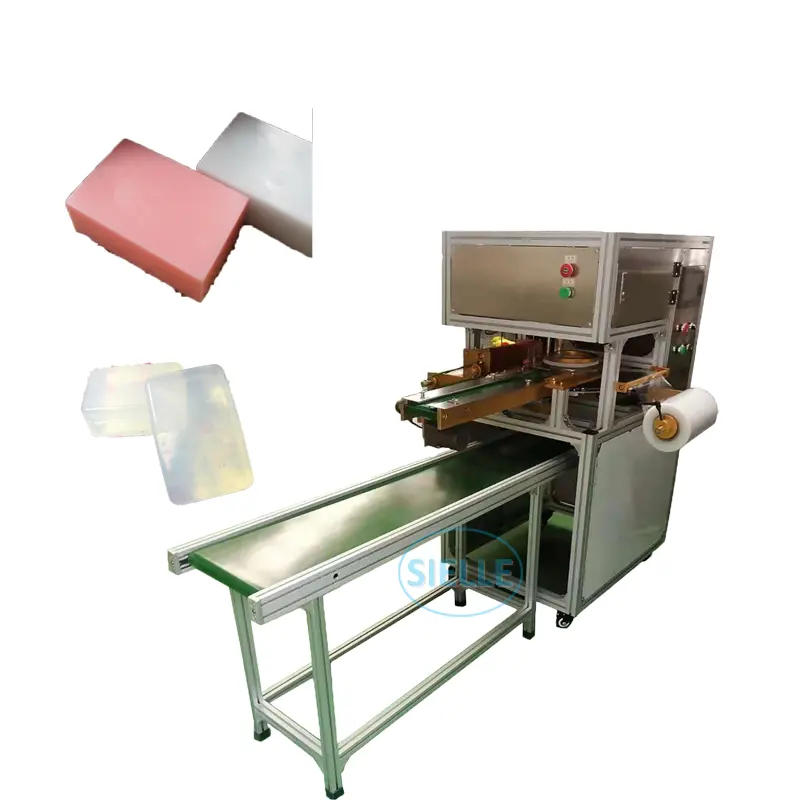

XQK/G300 Embossing &Cutting Machine

This machine can emboss and cut all kinds of toilet soap and laundry soap, fast and accurate. For toilet soap production, this machine will cut the soap billets from the plodder into long bars to feed into the downstream stamper. For the laundry soap production, a complete set of embossing mechanism can be installed at the front so that the machine can emboss and cut the soaps at the same time to product finished product for downstream packaging. This machine uses PLC for accurate control and HMI for easy operation.

Speed(bars/min) 180

Cutting Precision(g) ±1

Power(kW) 2+0.18

repeating accuracy. The suction cups pick up soap billet and put it onto the mould, then after forming, pick finished soap bars

out to discharge conveyor. The whole cycle is fully automatic, high speed, low vibration and solid performance. The control system

uses Schneider PLC and servo, HMI with English/Chinese operating screens. Electrical hand wheel is used for minor control, easy

for adjustment and mould replacement. Aluminum frame with safety door switches are used to ensure operators ‘safety.

NanTong Tongji Co., Ltd. established in 1997 .Our company is major in producing soap machines, toothpaste machines and packaging machines .

The packaging machines widely used in daily chemical,food,pharmaceutics,cosmetic ,etc.

As P&G's global strategic partner and appointed supplier for soap, toothpaste and packaging machinery, we've been serving P&G's factories world-wide.

Meanwhile, we've set up the global sales and after-sales network, serving more than 700 customers in more than 50 countries with quality machinery, including of Unilever, Reckitt Benckiser, Wilmar, Colgate, NICE, EVYAP, etc.

Our company has been awarded as national new high-tech enterprise by the government with 36 technical patents, classified as best credit rating of AAA, certificated by ISO9001: 2008, and got the CE and UL certification for the products with C3+ safety standards. And we have long-term tight cooperation relationship with some machinery manufactures in Italy, Germany and UK to continuously innovate and improve.