Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 0.28 $* | 0.20 $* |

| Aug-15-2025 | 0.9 $* | 0.2 $* |

| Jul-15-2025 | 0.26 $* | 0.46 $* |

| Jun-15-2025 | 0.40 $* | 0.65 $* |

| May-15-2025 | 0.30 $* | 0.63 $* |

| Apr-15-2025 | 0.19 $* | 0.22 $* |

| Mar-15-2025 | 0.89 $* | 0.18 $* |

| Feb-15-2025 | 0.76 $* | 0.30 $* |

| Jan-15-2025 | 0.68 $* | 0.4 $* |

Характеристики

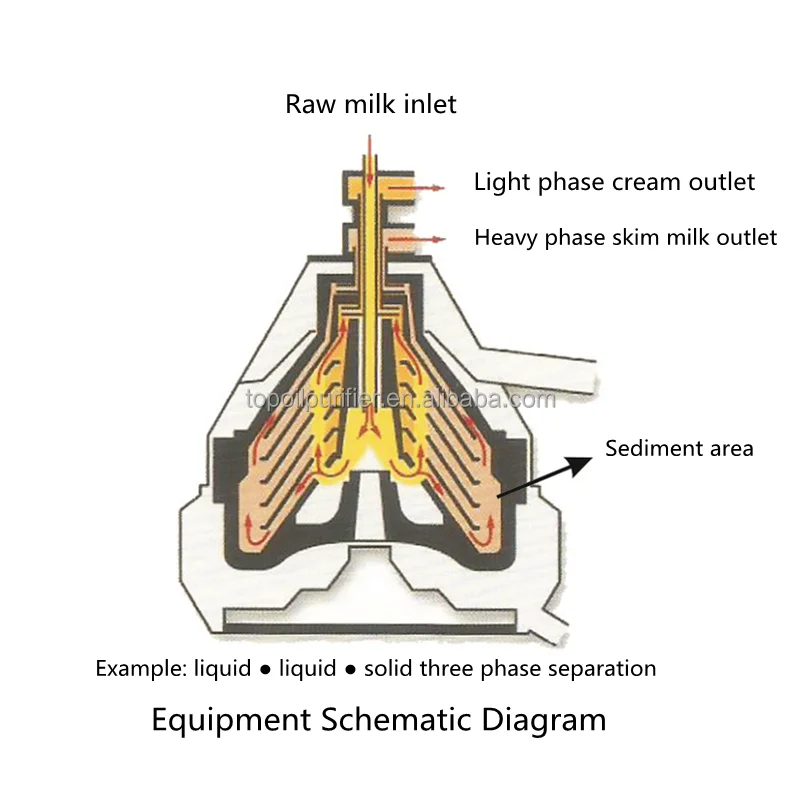

TP203-A Butterfly-type Centrifuge

Motor through the spiral gear drive for high speed rotary drum around the main axis, the material liquid feed pipe flow by the upper center to the bottom of the drum, the disc under the tap hole to drum wall below, under the effect of centrifugal force field, the heavier than liquid solid objects sink to the drum wall formation sediment, lighter fluid flows along the axis of conical disc outer cone to the first division by the lighter fluid to the heart pump, made of light fluid outlet. The heavy liquid moves toward the drum wall along the inner cone of the disc, and then toward. The upper flow through the heavy liquid centripetal pump is discharged from the heavy liquid outlet. The heavy liquid outlet is also equipped with a set of specific gravity rings, which are used to adjust the oil-water interface due to the different oil-water ratio and specific gravity difference of materials, so as to achieve a better separation index. The rotary drum of the equipment is balanced by precise motion, which makes the operation stable, safe and reliable. This machine is artificial slag cleaning type, simple operation, convenient disassembly and assembly.

Capacity | L/H | 1500 | |

Drum speed | r/min | 8300 | |

Drum diameter | mm | 230 | |

Separation ingredients | 9630 | ||

Slag discharge way | Artificial slag cleaning type | ||

The centripetal pump outputs pressure | Mpa | 0.2 | |

Motor power | KW | 3KW 380V | |

Net weight | KG | 240 | |

External dimensions of separator | L*W*H | 850*720*1000 | |

Gross weight | KG | 320 | |

1.1.Fully Automatic Karl Fischer Water Content Tester

TP-2100

2.Digital Karl Fischer Water Content Tester TP-6A

3.Kinematic Viscosity Tester VST-2000

4.Kinematic Viscosity Tester TPV-8

5.Kinematic Viscosity Tester VST-3000

6.Fully Automatic Oil Acidity Tester (6 cups) ACD-3000I

7.Fully Automatic Surface/Interface Tension Tester IT-800

8.Automatic Surface/Interface Tension Tester (Platinum Plate Method) IT-800P

9.Fully Automatic Open Cup Flash Point Tester TPO-3000

10.Fully Automatic Closed Cup Flash Point Tester TPC-3000

11.Digital Open Cup Flash Point Tester TPO-100

12.Digital Closed Cup Flash Point Tester TPC-100

13.Cloud Point & Pour Point Tester PT-2000

MOQ | 1 Set |

Trade Terms | EXW, FOB, CIF, CFR |

Payment Terms | T/T, L/C |

Port of Loading | Any Port of China |

Packing Method | Internaional Standard Wooden Case |

Transportation Method | By Sea, By Land, By Air, By Express |

Supply Capability | 100 Sets/Month |

* The warranty period is 24 months from commissioning acceptance date on. After the warranty period is over we provide lifelong maintenance and technical service.

* We guarantee the maintenance time no more than 3 working days and response time within 1 hour.

* We build instrument service profile for our clients to record the product service and maintenance conditions.

* After instruments start service, we will pay follow-ups to collect the service conditions.

Chongqing TOP Oil Purifier Co., Ltd

Located at Chongqing city--a southwest electromechanical manufacturing center as well as national municipality, Chongqing TOP is a professional leading manufacturer and supplier of oil purifiers and various related testers. Our company consists of departments respectively for technological development, machinery manufacture, instrument manufacture and quality control etc.

CHONGQING TOP OIL PURIFIER CO.,LTD

Manufacture oil purifiers and supply test equipment.

Add: No. 1, Jianlong N. Rd., Jiulongpo District, Chongqing, China

E: sales7@topoilpurifier.com

Cell: 0086-13340266216 (Whatsapp/Wechat) | Skype: topoilpurifier

Tel: 0086-23-88901306 | Fax: 0086-23-88901306

www.topoilpurifier.com; www.toptester.com.cn