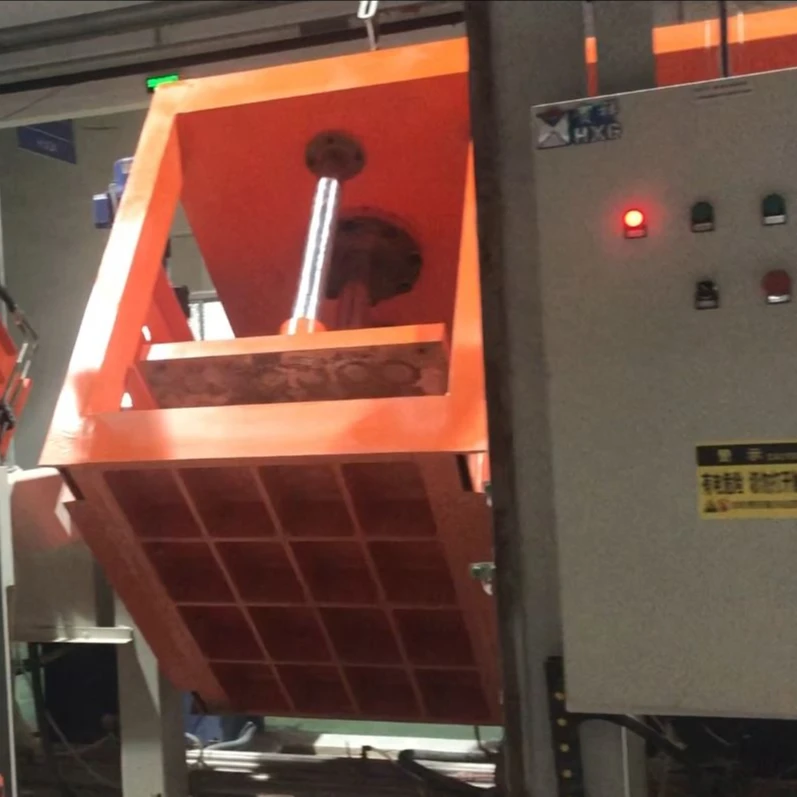

Санитарная посуда литейная машина высокого давления для двухкомпонентного шкафа с корпусом чаши выдвижной в конструкции скользящей

- Категория: Other Machinery & Industry Equipment >>>

- Поставщик: Tangshan,Hexiang,Intelligent,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 595000.85 $* | 624750.33 $* |

| Aug-17-2025 | 590000.92 $* | 619500.29 $* |

| Jul-17-2025 | 495000.79 $* | 519750.76 $* |

| Jun-17-2025 | 580000.74 $* | 609000.58 $* |

| May-17-2025 | 505000.18 $* | 530250.87 $* |

| Apr-17-2025 | 570000.54 $* | 598500.96 $* |

| Mar-17-2025 | 565000.17 $* | 593250.89 $* |

| Feb-17-2025 | 560000.91 $* | 588000.84 $* |

| Jan-17-2025 | 555000.58 $* | 582750.20 $* |

Характеристики

This pressure casting machine with 2-12 module can produce two piece toilet water closet, water closet bowl, intelligent toilet which is a modern high pressure casting equipment which integrates comprehensive technology of water, electricity, compressor air, hydraulic and vacuum.

As the first choice for modern sanitary ceramic factory and favorite of client, it is mainly applicable to cast and form green body of 1-piece toilet.

Its' advantage is: high output, low labor cost, energy saving and environmental protection, also it solves the problem of youth labor shortage.

The high pressure casting machine has the following characteristics:

1. Suitable for producing different model two piece toilet bowl, intelligent toilet.

2. Machine advantage:

Save 3mins mechanical motion time.

High auto control, low labor strength;

Small floor space with low building cost;

The machine chooses Siemen PLC 1500 series, can realize remoting control and fault eliminate, help factory to manage producing;

Choose Japan SMC pneumatic control system, Omron lighting control element, Germany IFM sensor, Hydraulic system adopts American Rexroth valve group, Germany Pepper Fuchs proximity switch, America Parker seal to make sure the machine stable running, reduce faults rate.

The machine adopts marine fluorocarbon paint, which has strong corrosion resistance in high temperature and high humidity environments.

No. | Items | Contents |

1 | Demoulding method | Vertical lifting+ Transverse horizontal+ vacuum suction+ compressed air |

2 | Mould close method | mould close by hydraulic |

3 | Pressure of mould close | 40-60T |

4 | Accurate of mould close | ±0.25mm |

5 | Working pressure intensity of this system | 18-20Mpa |

6 | Pressure of low-pressure slip feeding | 0.15-0.2MPa |

7 | Pressure of hi-pressure slip feeding | 0.8-1.0MPa |

8 | Method to increase pressure for slip feeding | Hydraulic pressurize or pneumatic pressurize |

9 | Pressure of compressed air | 0.6-0.8MPa |

10 | Air consumption (/module) | 0.2M³/h/station |

11 | Pressure of water resource | 0.3MPa |

12 | Water consumption (/module) | 0.025M³/h/station |

13 | Quantity of mould | 2-12 sets resin working mould |

14 | Total casting cycle | 20~25min/cycle (adjustable) |

15 | Total install power | 5.5kw/station +12kw(adjustable) |

16 | Method of green body taking | Lifting and down of mould to take the green base by automatically |

17 | Total weight | =11.3T/station + 13.5t |

18 | Dimension | L: 2500mm* station quantity+5300, W: 5750mm, H: 4000mm(max) |

19 | Hydraulic system flow | Low pressure 50L/Min, high pressure 5.1L/min; |

20 | Flow of hydraulic system of slip pressurize cylinder | 5.7L/Min |