2~100 tons per day special design Used black motor oil refining to group II base recycling

- Категория: Machine Oil Purifier >>>

- Поставщик: Vpure,(Chongqing),Petroleum,Engineering,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Aug-19-2025 | 7579100.40 $* | 7730682.50 $* |

| Jul-19-2025 | 6146829.19 $* | 6269766.31 $* |

| Jun-19-2025 | 7459744.29 $* | 7608939.29 $* |

| May-19-2025 | 7400066.50 $* | 7548067.69 $* |

| Apr-19-2025 | 5908117.93 $* | 6026279.3 $* |

| Mar-19-2025 | 7280710.99 $* | 7426324.28 $* |

| Feb-19-2025 | 7221032.72 $* | 7365453.57 $* |

| Jan-19-2025 | 7161354.28 $* | 7304581.43 $* |

Характеристики

2~100 tons per day special design Used black motor oil refining to group II base oil recycling machine

Any inquiry pls direct contact: +86-18725838198

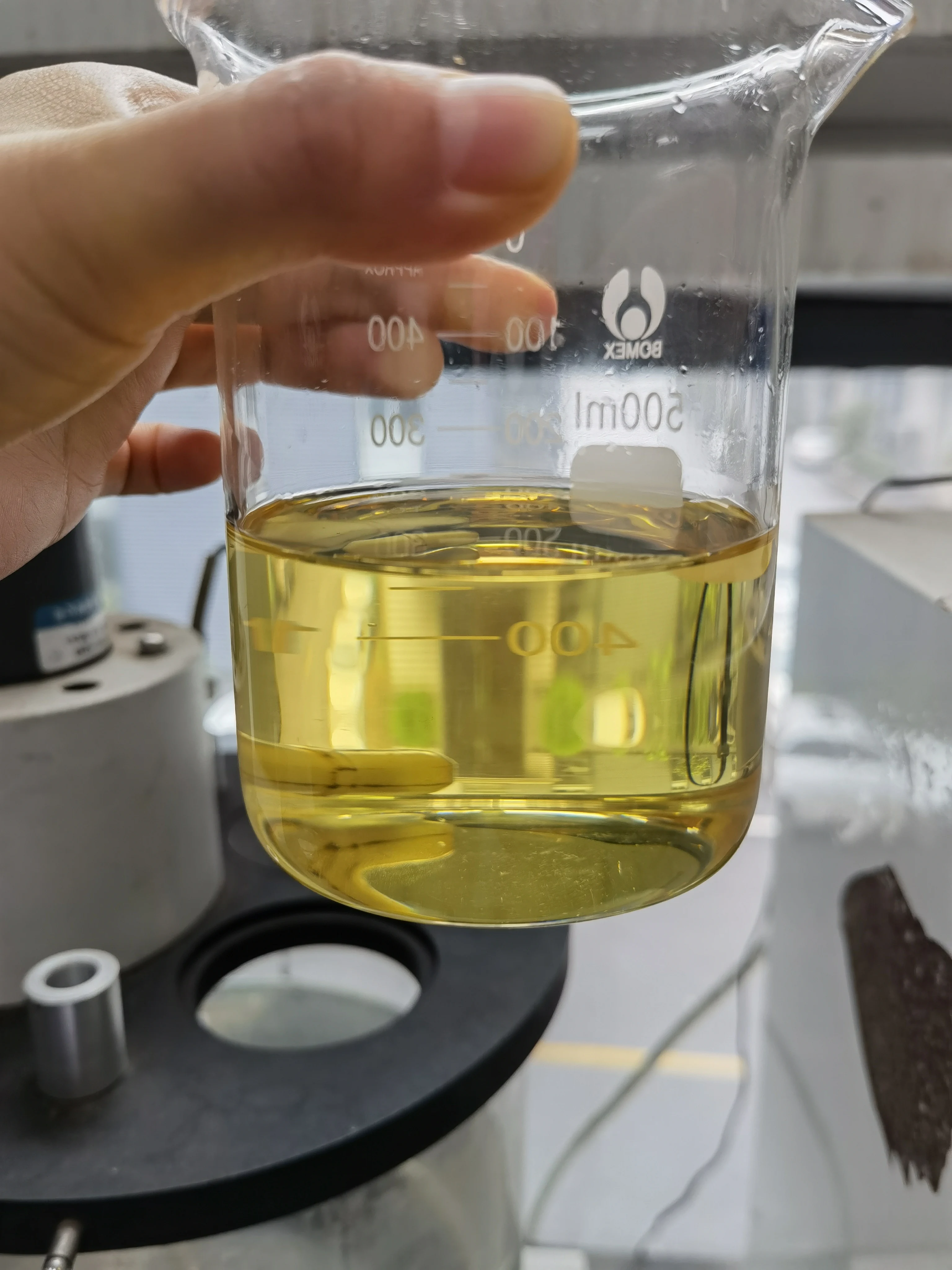

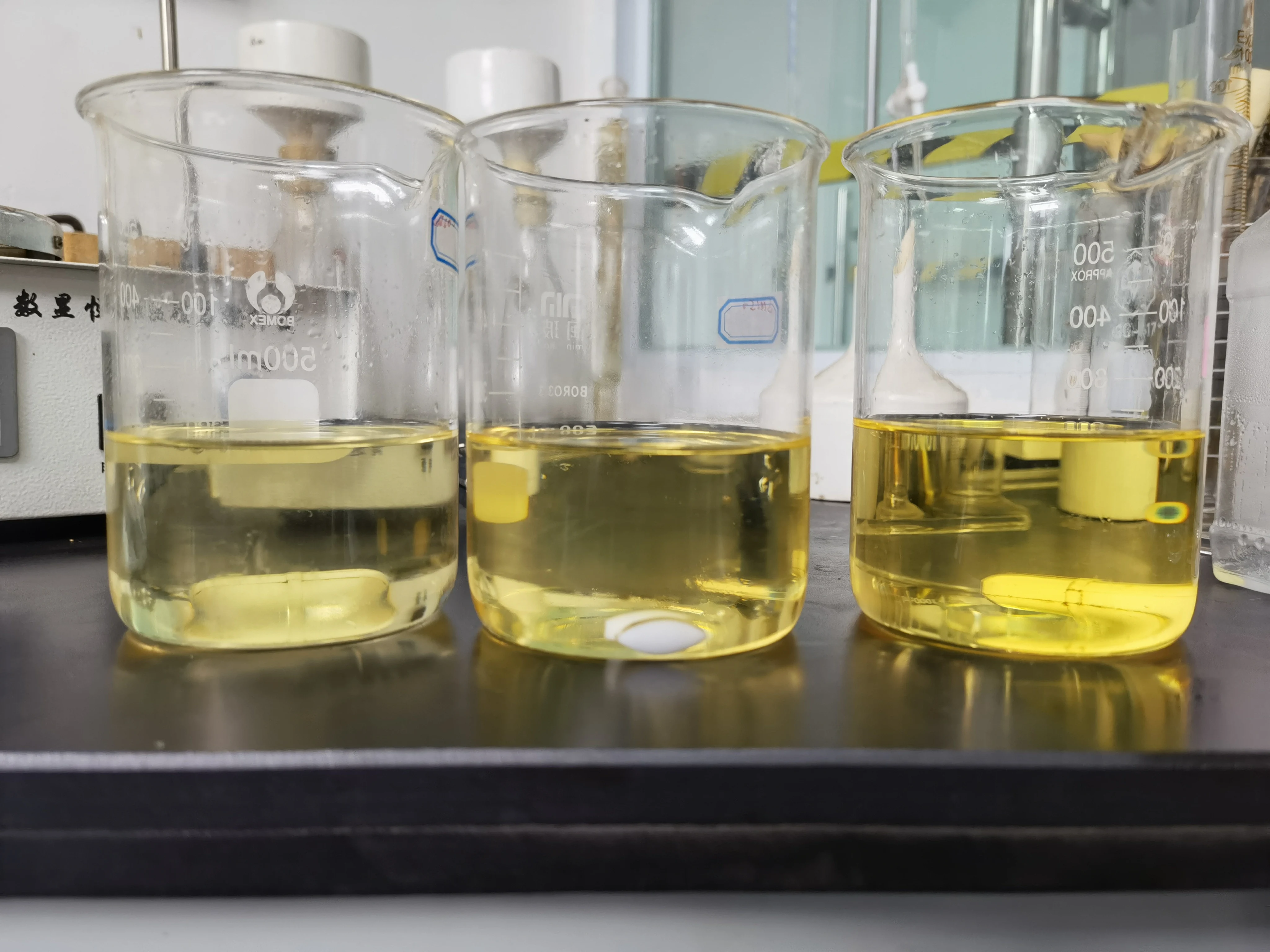

We are proud to present you with our VP-BP waste oil recycling plant which is combined with dozens of our newest technologies to delivery you with the excellent quality of base oils out of different type of car engine and machinery engine or industrial waste oil.

As the manufacturer, Vpure owns professional engineering team to provide constructively project proposal according to different waste oil feedstock or standard requirement of the final oil products. In order to get a golden clear distillates, genuine continuous fractional distillation, wiped film distillation and molecular distillation are optional. Before the process of distillation begins, we also highlight the equally important steps prior to vacuum distillation. A concurrent pretreatment solid removal and dehydration and defueling process could also upgrade the quality of oil products and increase the working efficiency.

SPECIFICATIONS OF VP-BP OIL RECYCLING MACHINE

| Model No. | VP-BP-1 | VP-BP-2 | VP-BP-3 | VP-BP-4 | VP-BP-5 | VP-BP-6 | VP-BP-7 | VP-BP-8 |

| Items. | ||||||||

| Process Capacity MAX. | 2 TPD | 5 TPD | 10 TPD | 15 TPD | 20 TPD | 30 TPD | 50 TPD | 100 TPD |

| Heating Power | 17KGS LPG/20KGS FUEL OIL/230KWH/PER TON OF WASTE OIL | |||||||

| Power Consumption | 25KWH PER TONS OF WASTE OIL | |||||||

| Vacuum Degree | Less than-0.05KPa | |||||||

| Heating Method | Fuel Oil/Natural Gas/LPG/Electricity | |||||||

| Heating Temp. | 30-350℃ | |||||||

| Voltage | 220/380/415V 50/60HZ | |||||||

| Noise | ≤60dB | |||||||

| PROPERTY | METHOD | RESULT UNITS | |||||

| Type | LBO | HBO | |||||

| Appearance | Visual Inspection | Bright&Clear | Bright&Clear | ||||

| Color scale | ASTM D1500 | ≤1 | ≤1.5 | ||||

| Water Content | ASTM D1744 | Trace (% wt) | Trace (% wt) | ||||

| Kinematic Viscosity at 40℃ | ASTM D445-15a | 32.170 mm2/s | 67.420 mm2/s | ||||

| Viscosity Index | ASTM D2270-10 | 117 | 122 | ||||

| Total Sulfur Content | ASTM D4294-16e1 | 0.0071 %(m/m) | 0.0093 %(m/m) | ||||

| Density at 15 ℃ | ASTM D4052-18 | 0.898 kg/m3 | 0.917 kg/m3 | ||||

| Pour Point | ASTM D97-17b | -18 ℃ | -21 ℃ | ||||

| Copper Strip Corrosion (3h/100℃) |

ASTM D130-18 | 1a Rating | 1a Rating | ||||

| Total Acid Number | ASTM D974 | 0.01(mg KOH/g) | 0.01(mg KOH/g) | ||||

| Carbon Residue Conradson | ASTM D189 | 0.01(% wt) | 0.01(% wt) | ||||

| Smell | Organoleptic | No Smell | No Smell | ||||

HIGH LIGHTS OF OUR PROCESS TECHNOLOGY

•ECO Friendly

• Non Acid

• High Yield of Base oil 80% or more subjected to purity of products as well as composition of Waste Oil.

• Genuine distillation with fractional column to produce much purer SN150, SN250, SN350 base oils.

• Stable Siemens PLC for automation with International standard CPU Modules.

• Transnational remote update and maintenance

• Easy operation

• Conversion of LGO & Residual Portion as salable Furnace Oil.

• Continuous distillation to save energy

Vpure (Chongqing) Petroleum Engineering Technology Co., Ltd. (the Vpure) was founded in 2013 and headquartered in Jiulongpo, Chongqing, China. The Vpure owns its unique engineers team to provide designs and manufactures complete, turnkey, skid mounted systems which recover near virgin grade base oil and diesel from waste lubricants. Vpure has been testing, engineering, designing, fabricating, installing and operating waste oil re-refining and distillation systems since its inception. Our mission is to facilitate environmental restoration, resource recovery and pollution reduction through innovative technologies and design, construction, and operation of affordable state-of-the-art waste recovery systems.

The Vpure currently focused on the waste oil recycling solutions. On the whole, the company's product ranges includes the following:

- Used lube oil re-refining system: refining used oil to API group I, API group II base lube oil.

- Catalytic cracking distillation machine: cracking waste oil to commerical standard diesel, ultra low sulfur diesel technical process is optional.

- Upgrade oil polishing equipment: to polish base lube oil or diesel to near virgin grade with water color.

- Solvent recovery plant: to recovery various solvent from waste.

- Machine lube oil purifier: to regenerate various machine lube oil from used.

OEM and ODM services are available.

What are the byproducts out from VP-LP waste oil to diesel fuel plant, how do I dispose it?

The byproduct are usually comprised of gas, water, oil sludge/residue and catalysts.

The gas will be purified before emission or to be recycled as heating fuel;

The water will be filtrated and purified as cooling water;

The oil sludge could be used for burning or to be raw material for producing asphalt or road constructions.

The catalysts can be reactivated by microwave or other technologies for reuse. Or to be handed over to the professional recycler for disposal.

What are the consumables of this distillation system? Are those additives required?

There are 2 consumables which will be needed for VP used tire recycling machine , one is our formulated catalyst, another one is refining adsorbent.

As a matter of fact, those consumables required for VP process are carefully selected and proved to be essential to the distillation/pyrolysis process even for those famous refineries from all over the world.

Please consult our sales for more information about the catalysts and what role it plays during the whole distillation process.

Are there any bad smell or odor from VP waste oil to diesel fuel plant while distillation system is working?

There will be no smell at all as the gas produced by VP used tire recycling machine will be purified by our exclusive tail gas purification unit before emission.

What is the yield of this distillation system?

Typically the yield of our distillation system is between 85-93.1% (depending on variations of water content, light HC and others ingredients from waste oil.)

What is the operation cost of this distillation system? How long can I take back my investment?

Please consult one of our sales representative for more information about operation cost and turnover of capacity you are interested. We will be providing you the professional budgets breakdown for your particular project.

Where is your factory located? Is it possible to see a live demo in your factory?

We are located in the Chongqing, China(a capital city in the south west of China), you are welcome to visit us in our factory and we will be showing you a live demo with actual waste oil for one of our distillation system. You could also check everything else of our machines and factory, after that we can have more discussion for the details of our waste oil distillation plant and the contract.

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com