Оборудование для литья под высоким давлением 4

- Категория: Other Machinery & Industry Equipment >>>

- Поставщик: Tangshan,Hexiang,Intelligent,Technology,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-18-2025 | 0.42 $* | 0.41 $* |

| Aug-18-2025 | 0.74 $* | 0.51 $* |

| Jul-18-2025 | 0.5 $* | 0.11 $* |

| Jun-18-2025 | 0.9 $* | 0.94 $* |

| May-18-2025 | 0.6 $* | 0.85 $* |

| Apr-18-2025 | 0.32 $* | 0.98 $* |

| Mar-18-2025 | 0.57 $* | 0.88 $* |

| Feb-18-2025 | 0.60 $* | 0.71 $* |

| Jan-18-2025 | 0.81 $* | 0.87 $* |

Характеристики

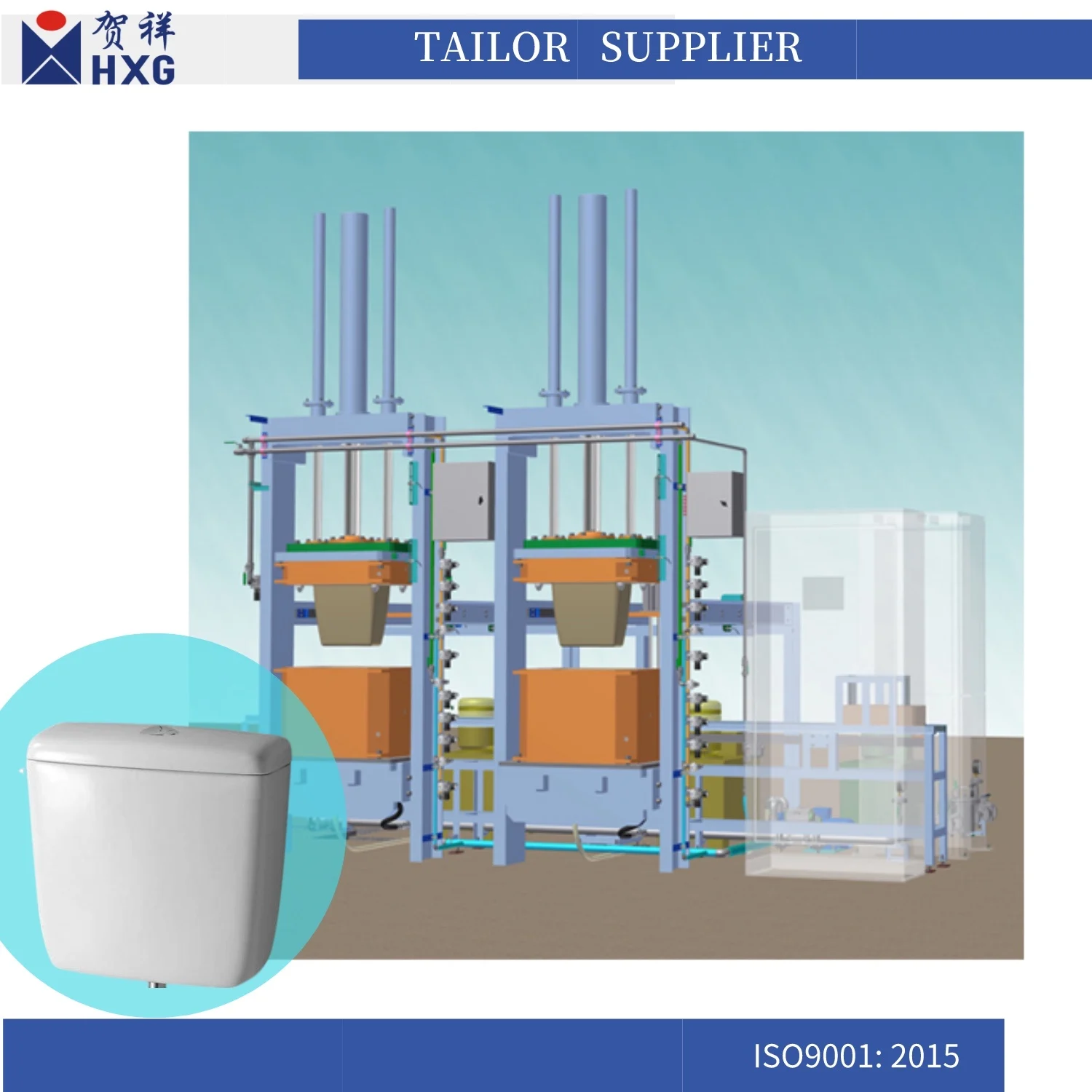

The 4 unit single mould cistern high pressure casting forming machine is modern high pressure casting equipment integrating water, electricity, compressor air, hydraulic and vacuum technologies. It is mainly used to cast sanitary ceramic tank. Tank and cistern High Pressure Forming Casting machine is the first choice for modern sanitary ceramic plant and factory. High output, low labor cost, energy saving and environmental protection are the main advantages of this equipment. This model conforms to the trend of youth labor shortage and is very popular in the current market.

4 moulds High Pressure Casting Machine for sanitary ware tank includes:

Main machine

Compressor air system

Hydraulic control system

Hydraulic pressurize casting system

Vacuum demolding system

Electric control system

Resin working mold

Electric control system divides two models of manual and auto,

It includes:

1. Siemens PLC

2. PLC 1200 series choose PROFINET communication protocol to realize the auto control of producing process.

3. Feedback system

4.Human-machine exchange interface to visual operate machine.

5.HMI

6.Electric control cabinet

7.Safety control system includes safety curtain and E-stop button

4Mold Hpcm-tank Main technical data | ||

Mould type | ||

Working mould type | Twin working mould | |

Mould parts | Inner mold and outer mold | |

Max products size | ||

Single | 400*200*400 | Mm |

Double | 400*200*420 | Mm |

Above products size depends on model. | ||

Max mold size | ||

Single | 800*600 | Mm |

Double | 1200*800 | Mm |

1. Suitable for producing different model tank.

Item No | Parts name | Brand | Remarks |

1 | PLC | Siemens | 1200-1500 Series |

2 | Touching screen | Kinco | |

3 | Pneumatic control cabinet | SMC | Integrated control |

4 | Pneumatic control elements | SMC | Air pipe, valve |

5 | Travel Switch | Schneider | |

6 | Proximity switch | Pepperl fuchs | |

7 | Water drop seperator | SMC | |

8 | Micro-mist seperator | SMC | |

9 | Cycle vacuum pump | Nash | |

10 | Speed control valve | SMC | |

11 | Cylinder | SMC | |

12 | Solenoid valve | SMC | |

13 | Reducing valve | SMC | |

14 | Electric elements | Schneider and Omron | |

15 | Safety curtain | Omron | |

16 | Hydraulic valve group | Rexroth | |

17 | Seal of hydraulic station | Parker |