Shanghai фармацевтический асептический высокопроизводительный выдувной герметичный наполнитель BFS Eye Drop 3-10 мл производственная

- Категория: Фармацевтическое оборудование >>>

- Поставщик: Shanghai,Marya,Pharmaceutical,Engineering,&,Project,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-17-2025 | 8965210.49 $* | 9413471.82 $* |

| Aug-17-2025 | 8889872.69 $* | 9334366.12 $* |

| Jul-17-2025 | 7458452.28 $* | 7831375.95 $* |

| Jun-17-2025 | 8739196.46 $* | 9176156.99 $* |

| May-17-2025 | 7609128.88 $* | 7989584.73 $* |

| Apr-17-2025 | 8588521.28 $* | 9017947.77 $* |

| Mar-17-2025 | 8513183.78 $* | 8938842.44 $* |

| Feb-17-2025 | 8437845.4 $* | 8859737.88 $* |

| Jan-17-2025 | 8362507.71 $* | 8780632.49 $* |

Характеристики

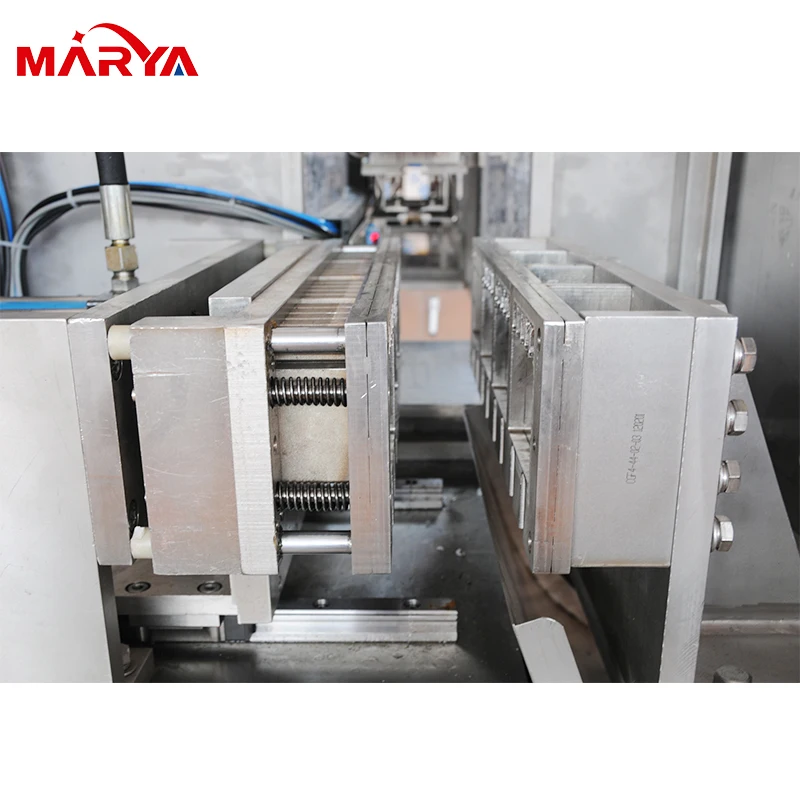

Shanghai Pharmaceutical Aseptic High Capacity Blowing Sealing Filling BFS Eye Drop 3-10 ml production Linkage Line (BFS machine for short) is an advanced technology that integrates molding, filling and sealing under complete control, which enables liquid to be packaged in polypropylene/high-density & low-density polyethylene plastic bottle, and the whole production process automatically completes the followings in a controlled environment (aseptic environment):

Ø Extrude plastic particles into plastic preform at high temperature.

Ø Then the preform is blown into a container by sterilized and filtered air.

Ø Filling liquid that have been sterilized and filtered.

Ø Tight sealing of containers after filling.

Ø BFS machine is suitable for liquid filling in pharmaceutical, chemical and food industries with aseptic or non-aseptic packaging in plastic containers.

Characteristics

Ø The design, MOC, manufacturing, assembly and debugging of the Pharmaceutical Three In One IV solution 500 ml blowing sealing filling BFS production Line meet the requirements of the new GMP standards for drug production.

Ø Advanced equipment, unique and reasonable structure, stable and reliable performance.

Ø Applicable Specification: 0.2ml-1000ml plastic bottle (as per user’s requirements).

Ø Production Capacity: 1000-18000BPH for Shanghai Pharmaceutical Aseptic High Capacity Blowing Sealing Filling BFS Eye Drop 3-10 ml production Linkage Line

Ø The number of bottles made each time: 1-30 bottles/mould, can be selected based on production capacity.

Ø Filling Accuracy: ≤ ±1% (according to drug characteristics)

Ø The BFS machine is integrated with bottle-making, filling and sealing, with compact structure and occupies small area, which reduces clean workshop area and saves energy consumption of air conditioning unit, as well as investment and use cost.

Ø The plastic particles are plasticized by a low speed long screw extruder driven by a specially designed servo motor, which can effectively reduce thermal stress of the material and accurately control the size of bottle preforms.

Ø Each working cycle of the equipment can be compared and controlled automatically, with real-time feedback.

Ø Stainless steel 304 hopper at extrusion station of the equipment is equipped with a level switch and linked with feeding device; when the material level is getting lowered, the alarm information of "lack of material" will be displayed on man-machine interface.

Ø High production efficiency, stable product performance, simple and reliable operation and beautiful appearance.

Ø For large capacity products, the container thickness is controlled at 100 points by an advanced thickness controller, and the precision servo motor controls the gap between mold core and mold cup.

Ø The filling system is accurately calculated by time pressure method with high filling precision, which can meet filling range of 0.2ml-2000ml to ensure production speed.

Ø The equipment has black and white sections, the moving parts are isolated in non-clean are(black area), and only the basic components and operations are kept in clean area(white area), which reduces the area of clean room and the number of particles in clean room.

Ø Automatic in-place cleaning / in-place sterilization function (CIP/SIP) can be realized.

Ø Configurable on-line monitoring system for dust particles and plankton bacteria.

Ø In the process of bottle transfer, the inner surface of interface is not in contact with parts, which eliminates the produce of visible foreign matter.

Ø To realize fully automatic control and monitor of production process, high precision color touch screen operation monitoring, PLC automatic control, automatic protection, host frequency conversion speed regulation and other control technology are used.

Ø The products can be customized according to actual demand of customers.

Standard export wooden case packaging .

Inner package: Stretching film

Delivery time:30-60 working days after receiving 30% deposit or L/C

Похожие товары

Данные ресурс не является интернет-магазином, а лишь содержит ссылки на международную торговую площадку Alibaba.com