Рулон для рулонной бумажной коробки машина ламинирования деревянной упаковки А4 Размер автоматическая пластиковой пленки холодный горячий

- Категория: Ламинаторы >>>

- Поставщик: Zhejiang,Cidihuakai,Import,And,Export,Trade,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-19-2025 | 83300.34 $* | 87465.28 $* |

| Aug-19-2025 | 82600.14 $* | 86730.83 $* |

| Jul-19-2025 | 69300.6 $* | 72765.75 $* |

| Jun-19-2025 | 81200.80 $* | 85260.17 $* |

| May-19-2025 | 70700.67 $* | 74235.85 $* |

| Apr-19-2025 | 79800.27 $* | 83790.47 $* |

| Mar-19-2025 | 79100.58 $* | 83055.8 $* |

| Feb-19-2025 | 78400.31 $* | 82320.29 $* |

| Jan-19-2025 | 77700.22 $* | 81585.80 $* |

Характеристики

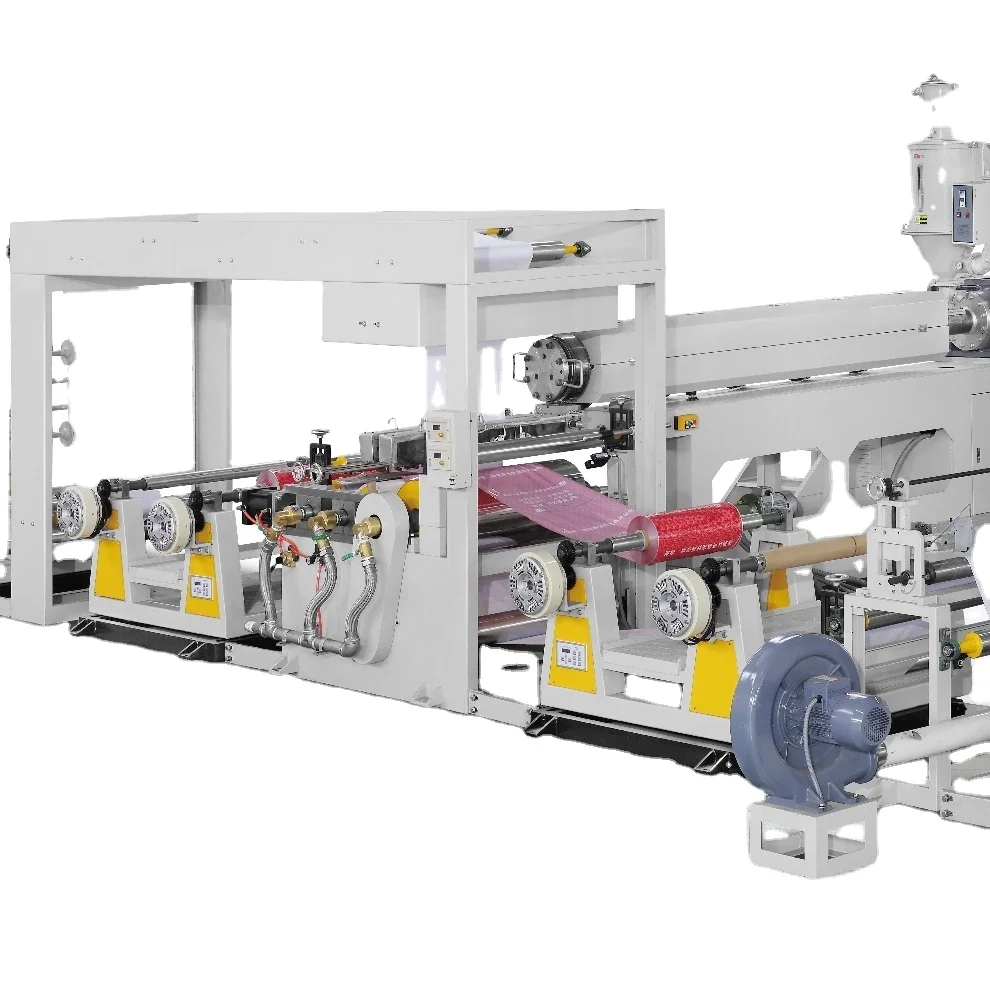

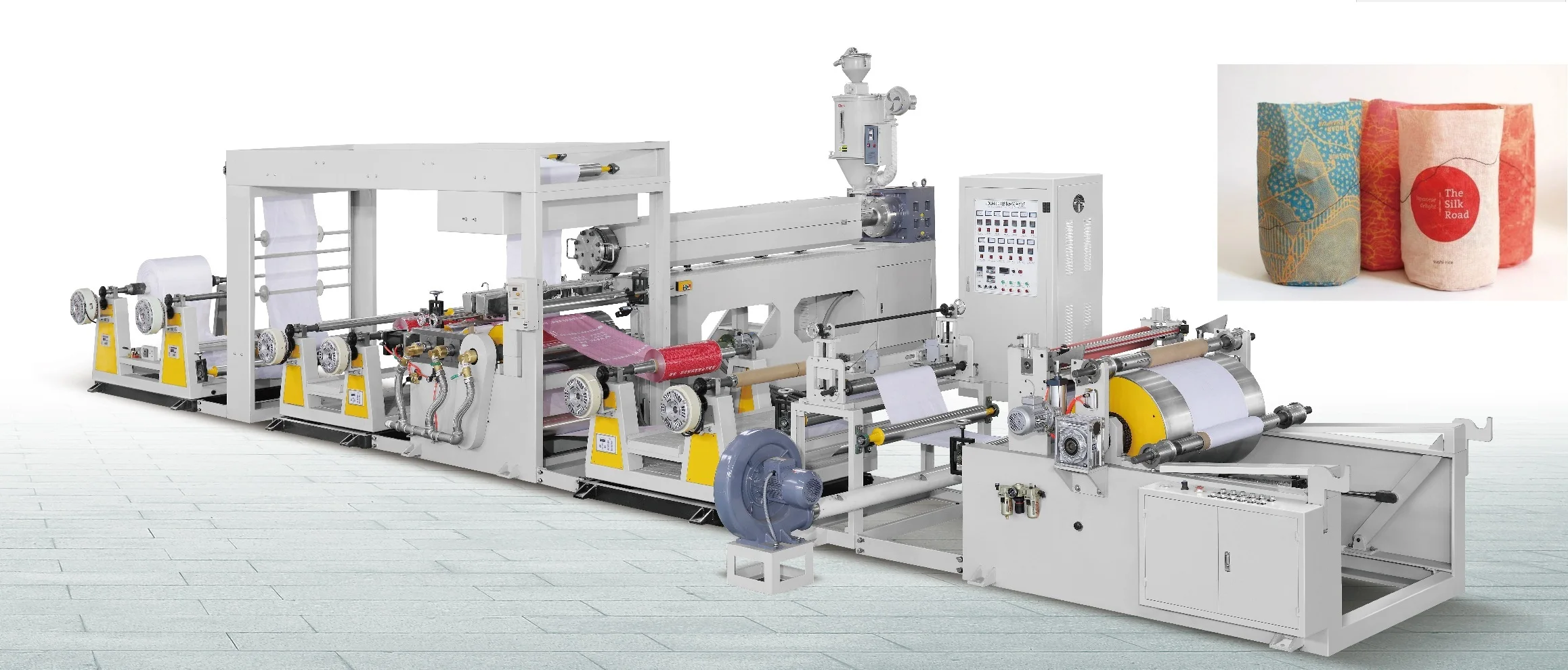

Product Picture

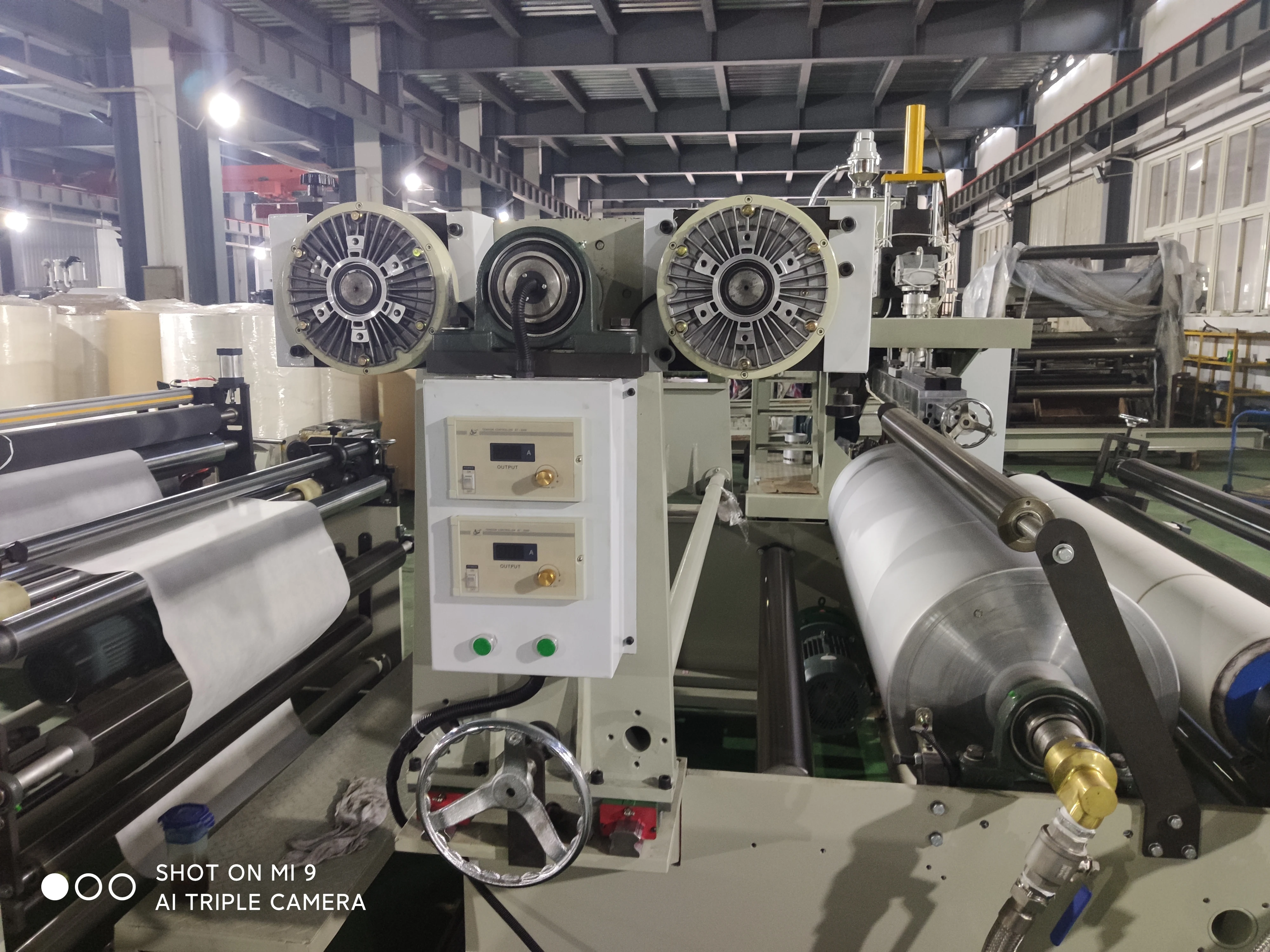

Sample Pictures

Video Description

Product Describe

The laminating machine use Grade material LDPE, LLDPE, PP and so on as raw materials, which is

specifically designed for online single-sided laminating of non-woven fabrics, woven bags and other products. In addition, it can also be used for paper base products.

specifically designed for online single-sided laminating of non-woven fabrics, woven bags and other products. In addition, it can also be used for paper base products.

Machine Components

Highlight

1. The machine cando stable coating at a high speed of 80-120M/Min.

2. Automatic Tension and EPC, so that the equipment has a higher coating precision. Then will reduce Labor cost.

3. Special Custermized Options, allow clients to modify what is needed. such as adding the return racksso that double-sided coating can be realized only with a single die, meanwhile the thickness of the double-sided coating can be consistent.

2. Automatic Tension and EPC, so that the equipment has a higher coating precision. Then will reduce Labor cost.

3. Special Custermized Options, allow clients to modify what is needed. such as adding the return racksso that double-sided coating can be realized only with a single die, meanwhile the thickness of the double-sided coating can be consistent.

Equipment Production Principle

The raw material of plastic pellets is heated, plasticized and extruded by the extruder. Pressurized and plasticized by staticmixer, extruded by T-die head, internal plugging die head adjusts the coating width without stopping the machine, and does not change the uniformity of the discharge thickness.

The main feeder feeds, corona, enters the laminating machine, laminating and cooling.

The winding machine is equipped with automatic tension control, and the pressure is controlled by precision pressure regulating valves at both ends of the air expansion shaft to ensure stable winding. Under normal circumstances, the winder changes the rolls at the same time after the material is changed to ensure that one joint has one roll of film.

The main feeder feeds, corona, enters the laminating machine, laminating and cooling.

The winding machine is equipped with automatic tension control, and the pressure is controlled by precision pressure regulating valves at both ends of the air expansion shaft to ensure stable winding. Under normal circumstances, the winder changes the rolls at the same time after the material is changed to ensure that one joint has one roll of film.

Product Paremeter

S/N | Item | Paremeter |

1 | Model | BT-JDLM 1300/80 |

2 | Screw Diameter | φ80 mm |

3 | L/D | 33:1 |

4 | Product Width | 600-1200MM |

5 | Coating | 0.01-0.10MM |

6 | Coating Material (Lamination Grade) | LDPE , LLDPE , PP,EVA,EAA |

7 | Designed Line Speed | 210M/MIN |

8 | Max Extrusion | 150kg/h |

9 | Main Motor | 30kw |

10 | Total Power | 77KW |

11 | Main Un-Winder | ≤φ1200 MM |

2nd Un-Winder | ≤φ500 MM | |

12 | Winder | ≤φ1200 mm |

13 | Weight | 6T |

14 | Overal Demension | 7400x7000x3200MM |

15 | Power Supply | 380/3/4/50(Volt/Ph/Line/Hz) |

Product configuration

Похожие товары

Машина для ламинирования мягкой пленки с жидким клеем

US $11000-$12000

Высокоскоростная машина для ламинирования рулонов без растворителей

US $80000-$120000

Деревообрабатывающая машина для ламинирования ПВХ пленки МДФ

US $8300-$52000