Автоматическая машина для формовки проволоки с ЧПУ 1 2-4 5 мм скручивания двойной

- Категория: >>>

- Поставщик: MYT,(Shanghai),Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-16-2025 | 0.99 $* | 0.77 $* |

| Aug-16-2025 | 0.8 $* | 0.19 $* |

| Jul-16-2025 | 0.25 $* | 0.17 $* |

| Jun-16-2025 | 0.41 $* | 0.6 $* |

| May-16-2025 | 0.45 $* | 0.24 $* |

| Apr-16-2025 | 0.70 $* | 0.54 $* |

| Mar-16-2025 | 0.37 $* | 0.78 $* |

| Feb-16-2025 | 0.33 $* | 0.98 $* |

| Jan-16-2025 | 0.37 $* | 0.84 $* |

Характеристики

Product Overview

MYT BRAND MCNC-1245 camless spring machine

Through the ingenious cam-free and rocker-free design, 12 servo motors respectively control the core parts, it can produce various special-shaped springs, compression springs, double torsion springs, battery springs, leaf springs (clockwork springs) and various wire forming Wait. The debugging of the machine is simple and fast, the processing process is stable and reliable, and the product precision is high.

PRODUCT SPECIFICATIONS

No | Model | MCNC-1225 | MCNC-1230 | MCNC-1245 | ||

1 | Color | Grey/Blue(customized) | Grey/Blue(customized) | Grey/Blue | ||

2 | Diameter of the steel wire(mm) | 0.5-2.5 | 1.2-3.0 | 1.5-4.5 | ||

3 | Total power(Kw) | 14.8 | 17.1 | 25.8 | ||

4 | Number of axes | `12 axes | `12 axes | `12 axes | ||

5 | Number of the wire feed wheel | 3 pairs | 3 pairs | 3 pairs | ||

6 | Servo motor | Wire feeding | 2.9KW | 4.5KW | 5.5KW | |

7 | Rotary wrie | 2.9KW | 2.9KW | 5.5KW | ||

8 | Rotary mandrel | 0.75KW | 1KW | 1.2KW | ||

9 | Curved shaft | 0.75KW | 1KW | 1.5KW | ||

10 | Knife rest of slide | 0.75KWx8 | 1.2KWx8 | 1.5KWx8 | ||

11 | Main machine(LxWxH)(mm) | 1550x1250x1770 | 1650x1350x1880 | 2200x1760x2100 | ||

12 | Net Weight of Machine(kg) | 1400 | 2000 | 3500 | ||

Detail images

Front profile

The machine adopts advanced industrial computer, combined with 12 servo motors to control 8 mechanical arms respectively, and 12 positions of wire feeding, wire transfer, core rotation, and cutter. Can easily complete the production of complex shapes.

Processing area

Through the coordination of eight mechanical arms, wire transfer, core rotation, wire feed, cutter and other 12 positions, various complex springs can be efficiently produced.

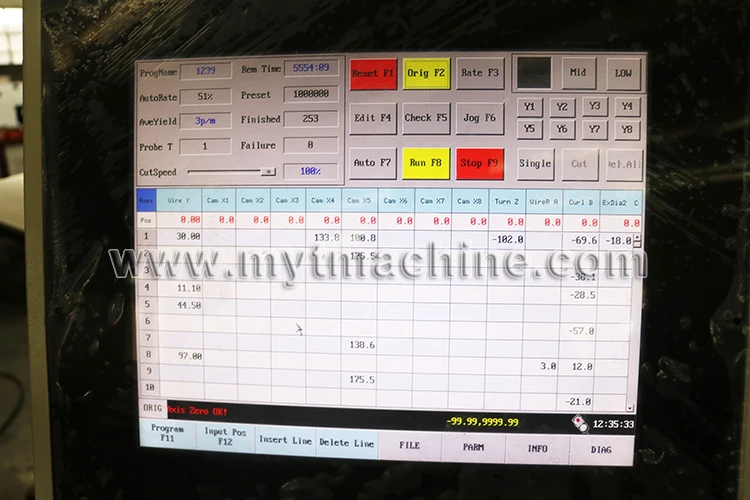

Computer console

Using world-renowned advanced industrial computers, it can efficiently combine 12 servo motors to complete high-precision processing. The operation is simple, the processing speed is fast, and a large number of processed graphics can be stored.

Induction probe

The length of the spring formed by the sensitive probe is controlled.

Portable handheld controller

When debugging the machine, the operator needs to stand in front of the machine and observe the processing process carefully, without access to the control computer. At this point, the portable handheld controller can better cooperate with the operator to complete the debugging process

Disconnection switch

The disconnection switch consists of three disconnection probes and a running alarm. The disconnection position is controlled by the sensitive probe to ensure the product length. During the processing, the running line alarm can assist the operator to quickly find the problem and ensure normal production.

Servo motor and feed wheel

MCNC-1245 adopts 12 Japanese Sanyo or Panasonic servo motors, which can easily complete the processing of various complex products. And equipped with 3 pairs of wire feeding wheels to ensure the stability of wire feeding.

Camless robotic arm

Through the control of the servo motor, the machining efficiency and accuracy of the camless spring machine are much higher than that of the traditional cam spring machine.

Company profile