Автоматическая машина для производства макаронных

- Категория: Машины для приготовления зерновых продуктов >>>

- Поставщик: Henan,Ocean,Machinery,Equipment,Co.,Ltd.

Поделиться:

Описание и отзывы

Трекер стоимости

| Месяц | Минимальная цена | Макс. стоимость |

|---|---|---|

| Sep-15-2025 | 15349.95 $* | 16116.38 $* |

| Aug-15-2025 | 15220.74 $* | 15981.80 $* |

| Jul-15-2025 | 12769.22 $* | 13407.47 $* |

| Jun-15-2025 | 14962.89 $* | 15710.2 $* |

| May-15-2025 | 13027.20 $* | 13678.29 $* |

| Apr-15-2025 | 14704.85 $* | 15439.74 $* |

| Mar-15-2025 | 14575.74 $* | 15304.84 $* |

| Feb-15-2025 | 14446.99 $* | 15168.36 $* |

| Jan-15-2025 | 14317.64 $* | 15033.98 $* |

Характеристики

Automatic pasta machine pasta production line macaroni pasta making machine![QQ20200528161141]()

| Brand | HNOC |

| Name | pasta making machine |

| Type | Automatic |

| Capacity | 2-10T/8H |

| Material | 304 Stainless Steel |

| Usage | Processing Macaroni Pasta |

| Size | 21000*1200*2200mm |

| MOQ | 1 SET |

| Packing | Wooden Case |

| Motor | ABB |

The production line of macaroni food is a small food made of flour, corn starch, potato starch, etc.After different molds can produce shells, spiral, square tube, 3D food, round tube, lotus root slice, conch snail, fat intestine and other innovative and unique shape products.

Can be used for cooking or frying, suitable for daily meals and restaurants.

Production line advantages:

1, feed, main drive, rotary cutting are used frequency conversion speed regulation system, strong power, stable operation, energy saving.

2. The extrusion system is equipped with multiple temperature control and automatic cooling devices, which makes the temperature control accurate and reliable.

3, the double helix forced feeding and photoelectric eye material tracking, feeding uniform, to prevent the lack of materials.

4.Raw material conditioning system can be configured to improve product quality.

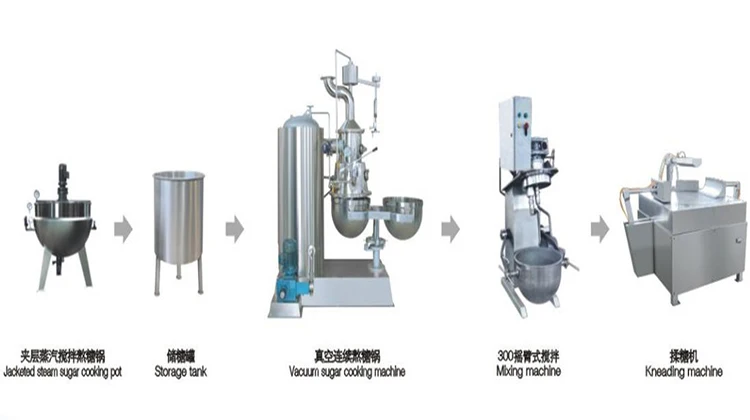

[production process]

Mixing of raw materials → extrusion molding (cutting molding →) → cooling → drying → cooling → packaging

Mixing of raw materials → extrusion molding (cut molding →) → cooling → drying → frying → deoiling → seasoning → cooling → packaging

[equipment configuration]

1) mix machine 2) spiral feeder 3) single screw bulking extruders

4) vibrating screen 5) plastic cutting machine 6) hoist

7) multilayer oven 8) fully automatic fryer 9) seasoning line

10) cooling machine 11) packaging machine

|  |  |

Henan Ocean Machinery Equipment Co.,Ltd.,

an ISO9001 certified and High-tech Enterprise established more than 10 years ago, is a professional manufacturer specialized in R&D, production and sales of Mechanical Equipment products such as Snack Food Processing Machine, Fruit and Vegetable Machine, Food & Packaging Machine, Water Well Drilling Rig and Poultry Equivalents, etc., which are widely sold worldwide and we have been recognized by our customers year after year.

On the principle "Customer-oriented, Quality First", Ocean Machinery is committed to providing our customers with high good quality products and perfect after-sale service.

1.Could we visit your factory to check the machine carefully and closely?

Highly appreciated factory visiting,will provide machines testing service,face-face discussing,turnkey project design solution.

2.How long is your machine's guarantee time?

Reply:1 year without normal wear parts,machine itself life guaranteed.

3.If we have very special request for the production lone,could you help me to do the design?

Reply:Experienced mechanical designer customized-design provided.

4.If we show you our layout of factory,can you help to design the whole process line?

Reply:Layout design service provided after received customer's factory layout size.

5.If we have samples of new products,can you help to analysis and design the machine?

Reply:Yes.Our technical department can help to analysis,design and test the new products you offered.